List Technical Parameters of “horizontal ffs machine”

Sure, here are the key technical parameters for a horizontal form-fill-seal (FFS) machine:

1. **Machine Dimensions**:

– Length, Width, Height

2. **Bag Dimensions**:

– Max. and Min. Length

– Max. and Min. Width

3. **Film Type**:

– Material compatibility (e.g., PE, PET, PP)

4. **Film Thickness**:

– Range (e.g., 20-100 microns)

5. **Film Roll Diameter**:

– Max. Roll Diameter

– Inner Core Diameter

6. **Sealing Type**:

– Heat Sealing

– Cold Sealing

7. **Sealing Temperature**:

– Adjustable range (e.g., 0 – 300°C)

8. **Sealing Pressure**:

– Adjustable range (e.g., 0-10 bar)

9. **Sealing Time**:

– Adjustable in milliseconds or seconds

10. **Production Speed**:

– Bags per minute (e.g., 20-100 BPM)

11. **Filling Volume**:

– Minimum and Maximum Volume (if volumetric filling)

12. **Dosage Accuracy**:

– Typically given as a percentage or weight range

13. **Power Supply**:

– Voltage (e.g., 220V, 380V)

– Frequency (e.g., 50Hz, 60Hz)

14. **Power Consumption**:

– Total wattage (e.g., 2 kW, 5 kW)

15. **Air Supply**:

– Pressure (e.g., 6-8 bar)

– Air Consumption (e.g., 0.5 cubic meters/hr)

16. **Control System**:

– PLC control

– HMI touch screen

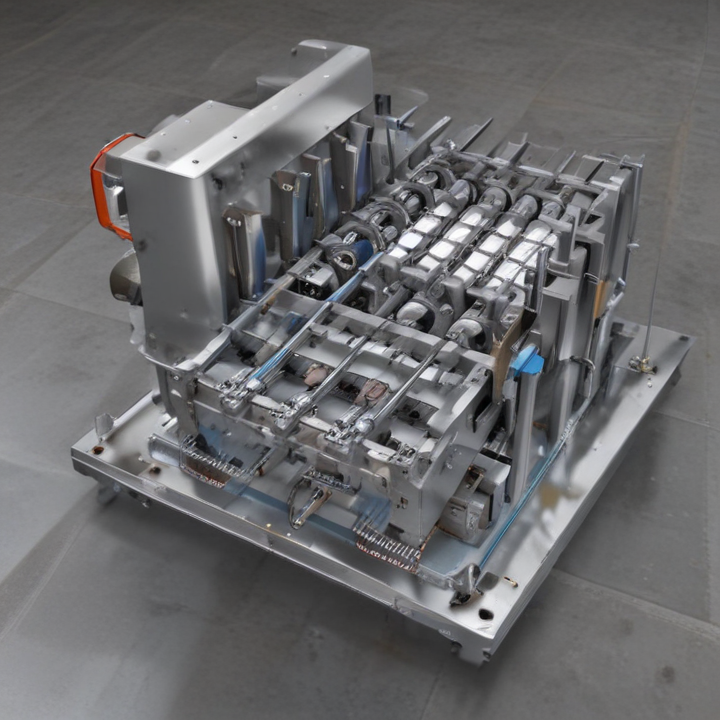

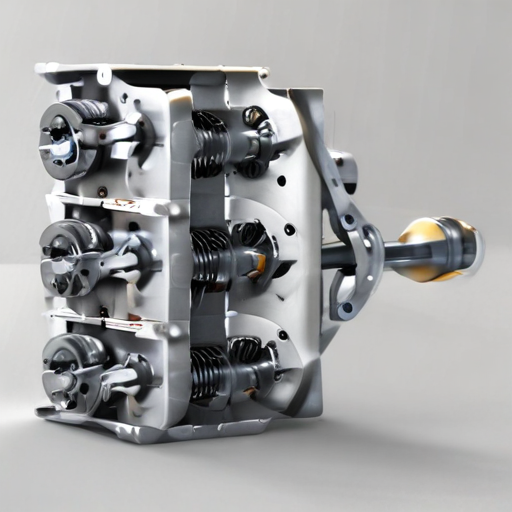

17. **Drive System**:

– Servo motors

– Pneumatic components

18. **Material Handling**:

– Conveyor type

– Product alignment features

19. **Machine Weight**:

– Total weight (e.g., 1500 Kg)

20. **Operating Environment**:

– Temperature range

– Humidity range

21. **Safety Features**:

– Emergency stop button

– Safety guards

22. **Compliance Standards**:

– CE, ISO, GMP

These parameters ensure the horizontal FFS machine is correctly specified and suited to the production requirements.

List Product features of “horizontal ffs machine”

A horizontal form-fill-seal (HFFS) machine is an automated packaging system that forms, fills, and seals products within a single continuous process. Key features include:

1. **Versatility**: Capable of handling various product types, including solids, liquids, powders, and granules.

2. **Customizable Packaging**: Supports different package shapes and sizes, such as pouches, sachets, and bags.

3. **High-Speed Operation**: Efficiently produces large quantities with high precision to meet industrial demands.

4. **Automation**: Reduces the need for manual intervention, enhancing productivity and consistency.

5. **User-Friendly Interface**: Equipped with an intuitive control panel, often touchscreen, for easy operation and adjustments.

6. **Material Compatibility**: Works with a range of packaging materials, including laminated films, paper, and foil.

7. **Accurate Dosing**: Ensures precise filling to maintain product consistency and minimize waste.

8. **Integrated Printing**: Allows for the inclusion of date codes, batch numbers, and branding directly on the package.

9. **Robust Construction**: Made from durable materials like stainless steel for longevity and hygiene.

10. **Multi-Lane Capability**: Some models can handle multiple lanes simultaneously, boosting output.

11. **Seal Integrity**: Provides reliable sealing methods, such as heat or ultrasonic sealing, to ensure product freshness and safety.

12. **Easy Maintenance**: Designed for straightforward cleaning and maintenance, reducing downtime.

13. **Safety Features**: Includes guards and interlocks to protect operators and comply with safety regulations.

14. **Energy Efficiency**: Optimized to consume less energy, lowering operational costs.

15. **Data Integration**: Supports connectivity for real-time monitoring and integration with existing production systems.

These features make HFFS machines a valuable asset for various industries, including food, pharmaceuticals, and consumer goods, offering efficiency, flexibility, and reliability.

List Application of “horizontal ffs machine”

Horizontal Form-Fill-Seal (HFFS) machines are versatile packaging systems primarily used in a variety of industries for efficient, high-speed packaging. Here are key applications:

1. **Food Industry**: HFFS machines package products like snacks, ready-to-eat meals, sauces, cream cheese, soups, confectionery items, dairy products, and coffee. They ensure airtight sealing, extending shelf life and maintaining freshness.

2. **Pharmaceuticals**: Used to package capsules, tablets, medical devices, and powders. The hermetic seals preserve product integrity and prevent contamination.

3. **Cosmetics and Personal Care**: Products such as creams, lotions, shampoos, and facial masks are packaged using HFFS machines. This facilitates precise portion control and offers tamper-evidence.

4. **Automotive and Industrial Goods**: HFFS machines package small mechanical parts, fasteners, and electrical components, ensuring they are protected from environmental factors like moisture and dust.

5. **Agriculture**: Seeds, fertilizers, pesticides, and other agricultural products are effectively packaged using HFFS machines. This not only protects the products but also makes handling and transportation easier.

6. **Pet Food**: Provides sealed packaging for dry and wet pet foods, ensuring freshness and ease of use for pet owners.

7. **Frozen Foods**: Items such as vegetables, fruits, and ready-to-cook meals are packaged to withstand low temperatures without compromising packaging integrity.

8. **Medical and Surgical Supplies**: Packaging of syringes, bandages, and diagnostic devices. The sterile packaging is crucial for maintaining the hygiene of medical supplies.

In summary, HFFS machines are integral to various industries for their ability to deliver high-speed, reliable, and flexible packaging solutions that help maintain product quality, safety, and consumer convenience.

List Various Types of “horizontal ffs machine”

Horizontal Form Fill Seal (FFS) machines are versatile packaging systems that create packages from a roll of film, fill them with product, and then seal them. Below are some common types of horizontal FFS machines:

1. **Pillow Pouch FFS Machines**:

– Create a simple, cost-effective pillow-shaped pouch.

– Commonly used for snacks, confections, and small items.

2. **Gusseted Pouch FFS Machines**:

– Feature side gussets to allow for more product volume.

– Ideal for products like coffee, pet food, and powders.

3. **Doypack or Stand-Up Pouch FFS Machines**:

– Pouches have a bottom gusset enabling them to stand upright.

– Popular for liquids, granules, and pet treats.

4. **Four-Side Seal Pouch FFS Machines**:

– Seal all four sides, offering both stability and a sleek look.

– Suitable for pharmaceuticals, condiments, and medical devices.

5. **Zipper Pouch FFS Machines**:

– Include a resealable zipper mechanism for convenience.

– Used for snack foods, dried fruits, and freezer items.

6. **Sachet Pouch FFS Machines**:

– Small, flat pouches typically used for single servings.

– Often found in sample sizes of shampoo, sauces, or spices.

7. **Stick Pack FFS Machines**:

– Create long, slender pouches.

– Perfect for single-serve applications such as powders, liquid supplements, and candies.

8. **Flow Wrap FFS Machines**:

– Wrap individual items or group of items horizontally in a continuous film.

– Widely used for biscuits, bars, and medical devices.

9. **Shrink Wrap FFS Machines**:

– Package is formed and then shrink-wrapped using heat.

– Commonly used in multipacks of bottled or canned beverages.

10. **Custom-Shaped Pouch FFS Machines**:

– Can create pouches in unique shapes tailored to brand aesthetics.

– Used for marketing-differentiated products or promotions.

Each type focuses on enhancing the shelf presence, storage convenience, and user experience, often tailored to the specific product requirements.

Custom Manufacturing Options for horizontal ffs machine

Custom manufacturing options for horizontal form-fill-seal (FFS) machines can significantly enhance performance and cater to specific production needs. Below are key customization possibilities:

1. **Material Handling**:

– **Film Type**: Customize for different film types (PE, PET, laminates).

– **Film Feeding**: Options for servo-driven systems for precise control.

2. **Sealing Technology**:

– **Heat Sealing**: Configure to either impulse or constant heat sealing.

– **Ultrasonic Sealing**: For sensitive materials requiring minimal thermal impact.

3. **Forming Configurations**:

– **Pouch Types**: Adapt to manufacture various pouch types (stand-up, pillow, gusseted).

– **Size Adjustment**: Quick change tooling for different pouch sizes.

4. **Filling Systems**:

– **Multi-ingredient Filling**: Support for powders, liquids, and solids.

– **Dosage Accuracy**: Advanced systems like multi-head weighers or volumetric fillers.

5. **Operational Control**:

– **Automation**: Integration with PLC and HMI for real-time monitoring and adjustments.

– **Speed Control**: Variable speed drives for flexibility in production rates.

6. **Quality and Safety**:

– **Validation Systems**: Vision systems for pouch integrity and print quality.

– **Safety Features**: Include interlocks, emergency stops, and protective guarding.

7. **Cleaning and Maintenance**:

– **CIP Systems**: Designed for easy cleaning in compliance with hygiene standards.

– **Tool-less Maintenance**: Simplified parts removal and reassembly.

8. **Integration Capabilities**:

– **Secondary Packaging**: Interfaces for automated cartoning and palletizing.

– **Industry 4.0**: Connectivity for data acquisition and predictive maintenance.

9. **Energy Efficiency**:

– **Eco-mode**: Energy-saving modes and efficient heating elements to reduce consumption.

Customizing an FFS machine ensures it aligns with specific operational requirements, enhancing productivity, and ensuring high-quality output.

List Quality Control and The Manufacturing Process of “horizontal ffs machine”

### Quality Control

1. **Raw Material Inspection**: All raw materials, such as metal sheets, electronic components, and plastic parts, are inspected for quality and compliance with industry standards before use.

2. **Component Testing**: Each component, from motors to sensors, undergoes functional testing to ensure it meets required specifications.

3. **In-Process Monitoring**: Continuous monitoring during assembly ensures that each step adheres to standards. This includes torque checks for screws and bolts, alignment verification, and weld quality inspection.

4. **Calibrations**: Regular calibration of measurement tools and instruments is performed to ensure accuracy.

5. **Final Machine Testing**: Completed machines are subjected to rigorous tests, including operational testing, speed tests, and safety checks to ensure they function as intended.

6. **Documentation and Traceability**: Detailed records are maintained for every machine, documenting inspections, tests, and any corrective actions taken, ensuring traceability and accountability.

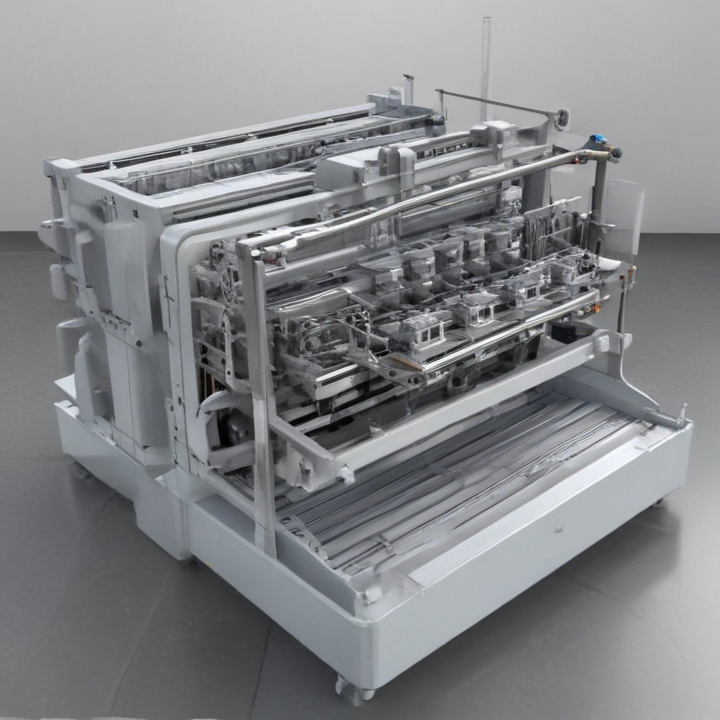

### Manufacturing Process

1. **Design and Planning**: Engineers create detailed designs and schematics, considering customer requirements and industry standards. Material requirements and manufacturing steps are also planned.

2. **Material Procurement**: Necessary raw materials and components are procured from approved vendors.

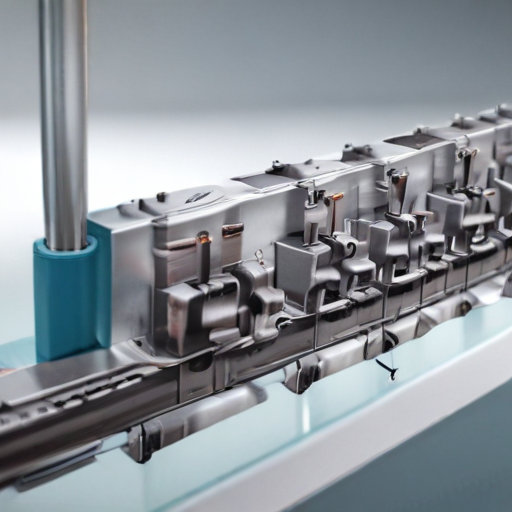

3. **Fabrication**: Materials are cut, machined, and welded into required shapes and forms. CNC machines and other fabrication tools are often used for precision.

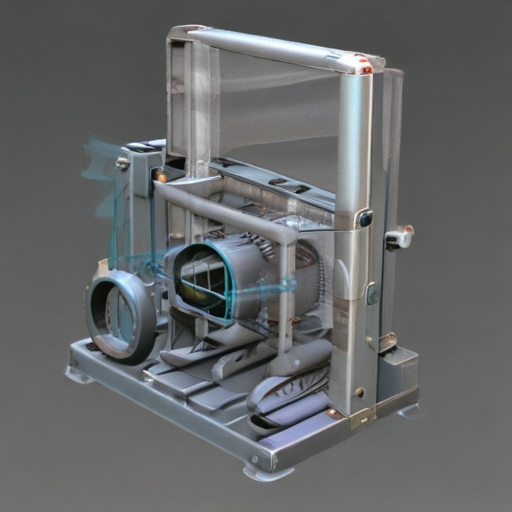

4. **Sub-Assembly**: Individual parts and components are assembled into modules, such as the feeding system, sealing system, and cutting mechanism.

5. **Main Assembly**: Sub-assemblies are brought together into the main frame, aligned, and interconnected, with wiring and plumbing completed.

6. **Software Installation**: Control software is installed, configured, and tested for functionality.

7. **Quality Control Testing**: The machine undergoes various quality control tests, as described above, to ensure performance and compliance.

8. **Packaging**: After final approval, the machine is cleaned, packed carefully to avoid damage during transit, and labeled for shipment.

9. **Shipping**: The finished machine is shipped to the customer with all the necessary documentation, including manuals and compliance certificates.

This concise overview ensures the production of high-quality horizontal FFS (Form, Fill, Seal) machines, balancing efficiency and reliability.

How to use “horizontal ffs machine”

A Horizontal Form Fill Seal (HFFS) machine is used primarily for packaging products in flexible pouches. Here’s a brief guide on how to use it:

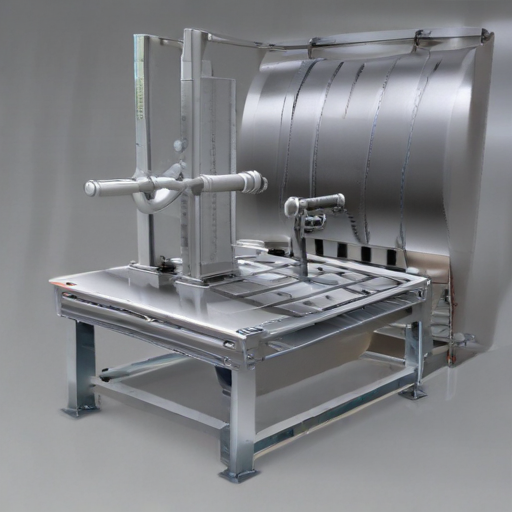

1. **Setup**:

– Place the film roll on the unwind station, ensuring it is correctly oriented.

– Thread the film through the machine, following the manufacturer’s diagram. Ensure the film goes through the forming area, seal bars, and cutting station.

2. **Programming**:

– Input the packaging parameters on the HMI (Human-Machine Interface). This includes pouch length, fill weight, and sealing temperatures.

– Adjust settings for different product types and sizes as needed.

3. **Product Loading**:

– Load the product into the hopper. The product can be powders, granules, or solid items.

– Ensure the product feeder is set to the correct speed and quantity for consistent filling.

4. **Machine Initialization**:

– Turn on the machine and do a trial run to produce a few pouches.

– Check the seal integrity, pouch length, and overall appearance. Adjust the settings if necessary.

5. **Operation**:

– Start the machine for continuous operation.

– The film will be pulled through the machine, formed into a pouch, filled with the product, sealed, and then cut into individual pouches.

6. **Monitoring**:

– Continuously monitor the machine for any issues such as film jams, incorrect fill weights, or poor seals.

– Regularly inspect finished pouches for quality assurance.

7. **Maintenance**:

– Perform regular maintenance as per the manufacturer’s guidelines. This includes cleaning the seal bars, checking for wear and tear, and lubricating moving parts.

– Keep the machine free of product residues to avoid contamination and ensure smoother operation.

By following these steps, the HFFS machine can efficiently produce high-quality pouches for various products. Always refer to the machine’s manual for specific instructions and troubleshooting.

List Properties and Terms of “horizontal ffs machine”

A Horizontal Form-Fill-Seal (HFFS) machine is a type of packaging equipment commonly used in various industries for creating and sealing packages. Below are the key properties and terms associated with HFFS machines:

### Properties:

1. **Orientation**: The machine operates horizontally, suitable for handling products that require gentle packaging.

2. **Flexibility**: Capable of packaging a diverse range of products, from solids and powders to liquids and semi-liquids.

3. **Speed**: Typically offers high-speed operation, enabling efficient mass production.

4. **Versatility**: Supports various packaging materials, including films, foils, and laminates.

5. **Customization**: Can be tailored to create different types of packages, such as sachets, pouches, and bags.

6. **Automation**: Often integrated with automated systems for product feeding, filling, and sealing to minimize human intervention and maximize efficiency.

### Terms:

1. **Film Unwind**: The step where packaging film is unwound from a roll and prepared for molding.

2. **Forming Station**: The section where the film is shaped into a pouch or sachet.

3. **Filling Station**: The area where products are filled into the formed packages.

4. **Sealing Station**: The point at which packages are sealed, typically using heat sealing.

5. **Cutting Station**: The stage where the sealed packages are cut and separated into individual units.

6. **Control Panel**: The interface for operators to control and monitor the machine’s functions and settings.

7. **Servo Motor**: Used for precise control of the machine’s movements and operations.

8. **Vacuum System**: Often employed to ensure proper product placement and film management.

9. **Dosing System**: Mechanism for accurately measuring and dispensing the product into the packaging.

10. **Web Tracking**: Ensures accurate alignment of the film to maintain package integrity and appearance.

### Summary:

HFFS machines provide an efficient and versatile solution for high-speed packaging of various products, utilizing automated and customizable processes to ensure precise filling, forming, and sealing.

List The Evolution history of “horizontal ffs machine”

The horizontal form-fill-seal (HFFS) machine has a rich evolutionary history, marked by technological advancements that have shaped modern packaging.

1. **Early Mechanization (1900s – 1930s)**: The advent of early mechanization in packaging began with rudimentary machines designed for simple filling and sealing tasks. These machines were manually operated and limited in functionality, focusing on basic applications like wrapping candies and filling bags.

2. **Emergence of Horizontal Form-Fill-Seal (1950s – 1960s)**: The concept of HFFS machines began to take shape with the development of more sophisticated automation technologies. These early HFFS machines were developed for packaging items like biscuits and soap bars, utilizing horizontal film feeding mechanisms to form pouches, fill them with product, and seal them.

3. **Advancements in Electronics (1970s – 1980s)**: The introduction of electronic controls and better materials science revolutionized HFFS machines. This era witnessed the incorporation of programmable logic controllers (PLCs) and servo motors, enhancing precision and versatility. The machines could handle a broader range of package shapes and sizes, improving efficiency in various industries from food to pharmaceuticals.

4. **Integration and Automation (1990s – 2000s)**: The integration of more advanced computer systems and automation technologies further improved HFFS machines. Features like touch-screen interfaces, real-time monitoring, and more sophisticated sealing technologies emerged. These improvements allowed for greater adaptability, better quality control, and reduced waste.

5. **Smart Technologies and Sustainability (2010s – Present)**: The latest generation of HFFS machines incorporates smart technologies, such as IoT (Internet of Things), AI (Artificial Intelligence), and machine learning. These machines offer predictive maintenance, enhanced traceability, and energy efficiency. Sustainability has also become a major focus, with machines designed to work with eco-friendly materials and reduce the carbon footprint.

The evolution of the HFFS machine reflects ongoing technological advancements aimed at improving efficiency, versatility, and sustainability in packaging processes.

How to Select a Reliable horizontal ffs machine

Selecting a reliable horizontal form-fill-seal (FFS) machine requires careful consideration of several key factors:

1. **Material Compatibility**: Ensure the machine can handle the types of materials you use, such as films, laminates, or foils.

2. **Production Speed and Efficiency**: Match the machine’s speed with your production requirements. Evaluate its cycle rates and downtime to ensure it meets your output needs.

3. **Versatility**: Look for machines that can handle various types of packaging, sizes, and formats, providing flexibility for future changes in product lineup.

4. **Ease of Use and Maintenance**: Opt for machines with intuitive interfaces and minimal maintenance requirements. Features like tool-less changeovers can save time and reduce operational complexity.

5. **Precision and Quality**: The machine should guarantee consistent sealing and cutting accuracy to maintain product quality and minimize waste.

6. **Reputation and Support**: Choose a machine from a reputable manufacturer with a track record of reliability and good customer service. Check reviews, ask for references, and ensure they offer robust support and training.

7. **Cost and ROI**: Evaluate the total cost of ownership, including initial investment, maintenance, and operational costs. Consider the long-term return on investment through increased efficiency and reduced labor costs.

8. **Compliance and Standards**: Ensure the machine complies with industry standards and regulations relevant to your product, such as food safety or pharmaceutical standards.

By focusing on these aspects, you can select a horizontal FFS machine that enhances your production efficiency and product quality.

List “horizontal ffs machine” FAQ

### Horizontal Form Fill Seal (FFS) Machine FAQ

**1. What is a Horizontal FFS Machine?**

A horizontal form fill seal (FFS) machine is an automated packaging machine that forms, fills, and seals products into pouches or bags on a horizontal plane. It’s commonly used in the food, pharmaceutical, and cosmetic industries.

**2. How Does a Horizontal FFS Machine Work?**

The machine forms pouches from a spool of flat packaging material, fills them with the product, and seals them. The process typically involves feeding the packaging material, forming it into the desired shape, filling the formed package with the product, and sealing it closed.

**3. What Types of Products Can Be Packaged?**

These machines can package a wide range of products such as powders, granules, liquids, and semi-solids like pastes. They are ideal for items like snacks, coffee, sauces, pharmaceuticals, and personal care products.

**4. What Are the Advantages of Using a Horizontal FFS Machine?**

– **Efficiency:** Automates the packaging process, reducing labor costs.

– **Versatility:** Can handle various product types and packaging materials.

– **Consistency:** Ensures uniform packaging and sealing quality.

– **Speed:** Capable of high-speed operation to meet production demands.

**5. What Materials Can Be Used for Packaging?**

Common materials include polyethylene, polypropylene, laminates, and co-extruded films. The choice depends on the product’s requirements and desired shelf life.

**6. Can the Machine Handle Multiple Packaging Sizes?**

Yes, most horizontal FFS machines are adjustable and can handle different pouch sizes by changing the machine settings or tooling.

**7. What Maintenance is Required?**

Regular maintenance includes cleaning, lubrication, and inspection of machine components for wear. Scheduled preventative maintenance can minimize downtime and extend machine life.

**8. How Do I Choose the Right Horizontal FFS Machine?**

Consider your product type, production volume, packaging material, and specific features you need such as speed, flexibility, and automation level. Consulting with a manufacturer or supplier can help tailor the machine to your requirements.

**9. Are There Any Limitations?**

While versatile, the machine may have limitations in packaging extremely delicate or oversized products. Customizations can address some limitations but may increase cost.

**10. What Are the Initial Costs?**

The cost varies widely based on features, size, and customization but generally ranges from tens of thousands to hundreds of thousands of dollars.

Always consult with a specialist to get the best configuration for your application.

Top 10 FAQ with answer about horizontal ffs machine for Buyer Sourcing from China

Certainly! Here are the top 10 Frequently Asked Questions (FAQ) about horizontal form-fill-seal (HFFS) machines for buyer sourcing from China, with concise answers:

1. **What is a Horizontal Form-Fill-Seal (HFFS) machine?**

– An HFFS machine is equipment used for automatic packaging where the product is loaded horizontally, and the machine forms, fills, and seals the packages in one continuous process.

2. **Why should I consider sourcing an HFFS machine from China?**

– China offers competitive pricing, advanced manufacturing capabilities, a vast selection of suppliers, and the ability to customize equipment to specific needs.

3. **How do I assess the quality of an HFFS machine from a Chinese supplier?**

– Check certifications (ISO, CE), request pre-shipment inspections, watch operation videos, and review customer testimonials or references.

4. **What are the lead times for manufacturing and shipping an HFFS machine from China?**

– Lead times typically range from 4 to 12 weeks, depending on customization and production schedules. Shipping times vary based on the destination and shipping method.

5. **What customization options are available for HFFS machines?**

– Customizations can include variations in machine size, packaging types, filling mechanisms, and specific automation requirements.

6. **Are there language barriers when dealing with Chinese suppliers, and how to overcome them?**

– Language barriers can exist, but many suppliers have English-speaking representatives. Using clear, written communication and third-party translation services can mitigate this issue.

7. **What payment terms are typically expected by Chinese suppliers?**

– Common terms include a downpayment (30-50%) before production starts and the remaining balance before shipping. Letters of credit (L/C) are also frequently used.

8. **What kind of after-sales support can I expect?**

– Reliable suppliers offer remote assistance, on-site training, spare parts availability, and sometimes local service centers or technicians.

9. **How do I ensure my HFFS machine complies with international standards?**

– Verify supplier certifications, comply with your country’s regulatory requirements, and specify any additional compliance needs in the contract.

10. **What are the essential factors to consider when choosing a supplier in China?**

– Evaluate the supplier’s manufacturing capability, quality control processes, experience in the industry, client references, and after-sales service.

By addressing these questions, you can make a more informed decision when sourcing HFFS machines from China.