-

- Packaging Equipment

- Bottling And Capping Machine

- Capping Machine

- Carton Packaging Machine

- Case Packing Machine

- Bagging Machine

- Bag Packing Machine

- Bag Filling Equipment

- Bag Handling Equipment

- Bag Labeling Machine

- Automated Bagging Machine

- Weighing And Bagging Machine

- Vertical Bagging Machine

- Seed Bagging Machine

- Bulk Bagging Machine

- Stand Up Bag Machine

- Vertical Bagging Equipment

- Poly Bag Packing Machine

- Drip Coffee Bag Packing Machine

- Weighing Packaging Machine

- Product Filling Machine

- Bottle Capping Machine

- High Speed Capping Machine

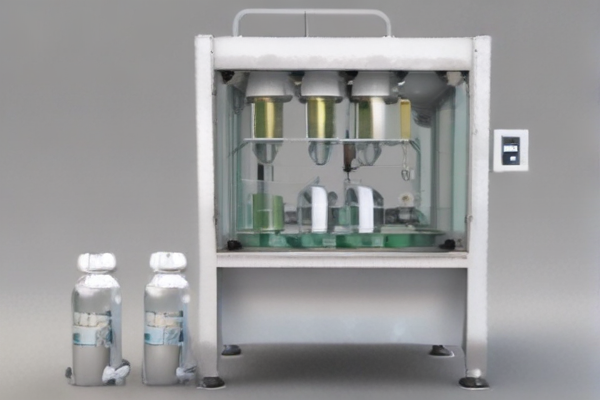

- Nasal Spray Filling Machine

- Filling And Capping Machine

- Weighing And Filling Machine

- Weigh Filling Equipment

- Net Weigh Filler Machine

- Pre Roll Filling Machine

- Form Fill Seal Machine

- Tray Filling Machine

- Spice Filling Machine

- Rotary Filling Machine

- Horizontal Form Fill And Seal Machine

- Container Filling Machine

- Container Filling Machines

- Counting And Filling Machine

- Cup Filling Equipment

- Cup Filling Machine

- Filling And Sealing Machine

- High Speed Filling Machine

- Sealing Machine

- Vacuum Packaging Machines

- Vertical Packaging Machine

- Tray Packaging Machine

- Food Packaging Machine

- Meat Poultry Packaging Machines

- Cheese Packaging Machines

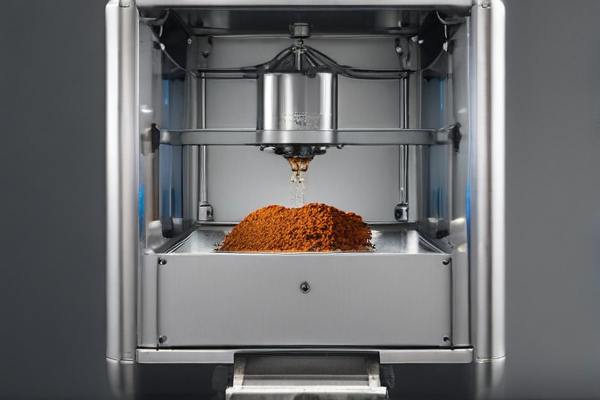

- Powder Packing Machine

- Food Packaging Machinery

- Food Packaging Equipment

- Frozen Food Packaging Machines

- Bulk Food Packaging Machine

- Candy Packaging Machine

- Coffee Packaging Equipment

- Snack Food Packaging Machinery

- Cannabis Packaging Machines

- Vegetable Packaging Machines

- Ice Cream Packaging Machine

- Pasta Packing Machine

- Sugar Packing Machine

- Chips Packing Machine

- Pet Food Packaging Machines

- Fruit Vegetable Packaging Machines

- Rice Packing Machine

- Salt Packing Machine

- Seeds Packing Machine

- Snack Packaging Machine

- Pouch Packaging Machine

- Container Packaging Machine

- Flow Pack Machine

- Primary Packaging Machines

- Specialized Packaging Machines

- Post Printing Machines

- Shrink Wrapping Machine

- Tube Packaging Machine

- High Speed Wrapping Machine

- Box Forming Machine

- Secondary Packaging Machine

- Automation

- Automatic Packaging Equipment

- Packaging Label Machine

- Packaging Machinery

- Palletizer System

- Self Service Equipment

- Visual Inspection Equipment

- Inspection Equipment

- Optical Counting Machine

- Depositing Equipment

- Depositor Machine

- Front And Back Labeling Machine

- Auxiliary Packaging Equipment

- Canada Packaging Machines

- Products List

- Industries Application

- Nutraceutical Pharmaceutical Packaging Machines

- Biomass Industry Packing Machine

- Fertilizer Packaging

- Candy Packaging Machines

- Cannabis Packaging Machines

- Flour Packing Machine

- Chemical Packaging Machine

- Powder Packaging Machines

- Bakery Packaging Machines

- Beauty Cosmetic Packaging Machines

- Granola Packaging Machine

- Food Packaging Machine

- Coffee Packaging Machines

- Candy Packaging Machines

- Cannabis Packaging Equipment

- Vegetable Packaging Machine

- Coffee Packaging Machine

- Mushroom Packaging Machine

- Cookie Packaging Machine

- Meat Poultry Packaging Machines

- Pet Food Packaging Machines

- Snack Packaging Machine

- Granule Packing Machine

- Seafood Packaging Machine

- Fast Food Packaging Machine

- Ice Cream Packaging Machine

- Sugar Packing Machine

- Salt Packing Machine

- Rice Packing Machine

- Cheese Packaging Machines

- Alcohol Filling Machine

- Chemical Packaging Machine

- Hardware Packaging Machine

- Fastener Packaging Machine

- Blog

- Contact

- Newsletter

- Whatsapp 8615951276160

- Packaging Equipment

- Bottling And Capping Machine

- Capping Machine

- Carton Packaging Machine

- Case Packing Machine

- Bagging Machine

- Bag Packing Machine

- Bag Filling Equipment

- Bag Handling Equipment

- Bag Labeling Machine

- Automated Bagging Machine

- Weighing And Bagging Machine

- Vertical Bagging Machine

- Seed Bagging Machine

- Bulk Bagging Machine

- Stand Up Bag Machine

- Vertical Bagging Equipment

- Poly Bag Packing Machine

- Drip Coffee Bag Packing Machine

- Weighing Packaging Machine

- Product Filling Machine

- Bottle Capping Machine

- High Speed Capping Machine

- Nasal Spray Filling Machine

- Filling And Capping Machine

- Weighing And Filling Machine

- Weigh Filling Equipment

- Net Weigh Filler Machine

- Pre Roll Filling Machine

- Form Fill Seal Machine

- Tray Filling Machine

- Spice Filling Machine

- Rotary Filling Machine

- Horizontal Form Fill And Seal Machine

- Container Filling Machine

- Container Filling Machines

- Counting And Filling Machine

- Cup Filling Equipment

- Cup Filling Machine

- Filling And Sealing Machine

- High Speed Filling Machine

- Sealing Machine

- Vacuum Packaging Machines

- Vertical Packaging Machine

- Tray Packaging Machine

- Food Packaging Machine

- Meat Poultry Packaging Machines

- Cheese Packaging Machines

- Powder Packing Machine

- Food Packaging Machinery

- Food Packaging Equipment

- Frozen Food Packaging Machines

- Bulk Food Packaging Machine

- Candy Packaging Machine

- Coffee Packaging Equipment

- Snack Food Packaging Machinery

- Cannabis Packaging Machines

- Vegetable Packaging Machines

- Ice Cream Packaging Machine

- Pasta Packing Machine

- Sugar Packing Machine

- Chips Packing Machine

- Pet Food Packaging Machines

- Fruit Vegetable Packaging Machines

- Rice Packing Machine

- Salt Packing Machine

- Seeds Packing Machine

- Snack Packaging Machine

- Pouch Packaging Machine

- Container Packaging Machine

- Flow Pack Machine

- Primary Packaging Machines

- Specialized Packaging Machines

- Post Printing Machines

- Shrink Wrapping Machine

- Tube Packaging Machine

- High Speed Wrapping Machine

- Box Forming Machine

- Secondary Packaging Machine

- Automation

- Automatic Packaging Equipment

- Packaging Label Machine

- Packaging Machinery

- Palletizer System

- Self Service Equipment

- Visual Inspection Equipment

- Inspection Equipment

- Optical Counting Machine

- Depositing Equipment

- Depositor Machine

- Front And Back Labeling Machine

- Auxiliary Packaging Equipment

- Canada Packaging Machines

- Products List

- Industries Application

- Nutraceutical Pharmaceutical Packaging Machines

- Biomass Industry Packing Machine

- Fertilizer Packaging

- Candy Packaging Machines

- Cannabis Packaging Machines

- Flour Packing Machine

- Chemical Packaging Machine

- Powder Packaging Machines

- Bakery Packaging Machines

- Beauty Cosmetic Packaging Machines

- Granola Packaging Machine

- Food Packaging Machine

- Coffee Packaging Machines

- Candy Packaging Machines

- Cannabis Packaging Equipment

- Vegetable Packaging Machine

- Coffee Packaging Machine

- Mushroom Packaging Machine

- Cookie Packaging Machine

- Meat Poultry Packaging Machines

- Pet Food Packaging Machines

- Snack Packaging Machine

- Granule Packing Machine

- Seafood Packaging Machine

- Fast Food Packaging Machine

- Ice Cream Packaging Machine

- Sugar Packing Machine

- Salt Packing Machine

- Rice Packing Machine

- Cheese Packaging Machines

- Alcohol Filling Machine

- Chemical Packaging Machine

- Hardware Packaging Machine

- Fastener Packaging Machine

- Blog

- Contact