List Technical Parameters of “gutkha packing machine”

A “gutkha packing machine” is designed to automate the packaging process of gutkha, a type of chewing tobacco. Here are the key technical parameters:

1. Production Capacity: Typically ranges from 40-200 packs per minute, depending on the model and specific requirements.

2. Power Specification: Generally operates on 220V single-phase or 380V three-phase power supply with power consumption around 2-6 kW.

3. Machine Dimensions: Generally around 1000mm x 800mm x 1600mm, though this can vary based on design specifications.

4. Weight: Typically between 300-700 kg, depending on the model and build materials.

5. Packaging Material: Compatible with a variety of films such as polyester, aluminum foil, and laminated films.

6. Film Width: Supports widths commonly ranging from 100mm to 300mm, depending on the required pouch size.

7. Sealing Type: Heat sealing, which can include both vertical and horizontal sealing mechanisms.

8. Pouch Formats: Can handle various types such as pillow packs, three-side seal, four-side seal, or center seal.

9. Filling Mechanism: Generally utilizes volumetric cup fillers or auger fillers to ensure consistent product dosing.

10. Control System: Incorporates PLC (Programmable Logic Controller) with HMI (Human-Machine Interface) for easy operation, adjustment, and monitoring.

11. Sensors: Equipped with photoelectric sensors for precise cutting and alignment.

12. Speed Control: Variable speed control through frequency inverters for adaptable packaging speeds.

13. Accuracy: High filling accuracy, generally ±1-2% variance.

14. Build Material: Made from stainless steel to ensure hygienic conditions and durability.

15. Hopper Capacity: Usually ranges from 10-30 kg, to accommodate substantial quantities for continuous production.

16. Compatibility: Supports various pack sizes and weights, often up to 100 grams per pouch.

17. Automation: Options for different levels of automation including semi-automatic and fully automatic models.

18. Safety Features: Includes emergency stop switches, overload protection, and compliance with industrial safety standards.

These parameters collectively ensure efficient, accurate, and versatile packaging to meet industrial requirements.

List Product features of “gutkha packing machine”

A “gutkha packing machine” is designed to efficiently package gutkha, a chewing tobacco product that often includes crushed areca nut, betel leaf pastes, and flavorings. Here are the key features of a gutkha packing machine:

1. High-Speed Packaging: Capable of packaging several pouches per minute, ensuring efficient production.

2. Precision Sealing: Ensures airtight and tamper-proof sealing to maintain product freshness and longevity.

3. Automated Operation: Features full automation for filling, sealing, cutting, and ejecting pouches, reducing manual labor and enhancing productivity.

4. User-Friendly Interface: Touchscreen controls and adjustable settings provide ease of operation for users with minimal technical expertise.

5. Material Compatibility: Compatible with a variety of packaging materials such as laminated films, aluminum foil, and multi-layered pouches.

6. Size Flexibility: Adjustable to accommodate different pouch sizes and volumes for varied product offerings.

7. Accurate Dosing: Equipped with sensors and advanced dosing systems for precise measurement of gutkha, minimizing waste and ensuring consistency.

8. Hygienic Design: Constructed with food-grade materials and stainless steel components to ensure hygiene and easy cleaning.

9. Low Maintenance: Engineered for durability with components that require minimal maintenance, resulting in lower downtime and higher efficiency.

10. Safety Features: Includes multiple safety mechanisms such as emergency stops and protective guards to ensure operator safety.

11. Integration Capabilities: Can be integrated with other equipment like weighing scales, labelers, and printers for a seamless production line.

12. Energy Efficient: Designed to consume less power, contributing to cost savings and a reduced environmental footprint.

13. Versatile Applications: While specialized for gutkha, it can often be adapted to pack other granular or powder products.

These features collectively ensure that gutkha packing machines offer reliable, high-speed, and efficient solutions for gutkha manufacturers.

List Application of “gutkha packing machine”

Gutkha packing machines are specialized equipment designed to automate the packaging process of gutkha, a chewable tobacco product popular in some parts of South Asia. Here are some key applications of gutkha packing machines:

1. Mass Production:

– Efficiency: Automates the packing process, increasing the speed and volume of production.

– Consistency: Ensures uniformity in the weight and size of each packed unit.

2. Hygienic Packaging:

– Sanitation: Reduces human contact with the product, maintaining hygiene standards.

– Sealing Quality: Provides better sealing, protecting the product from moisture and contamination.

3. Cost Reduction:

– Labor Savings: Minimizes the need for manual labor, reducing operational costs.

– Material Efficiency: Optimizes the use of packing materials, decreasing waste.

4. Branding and Marketing:

– Customization: Allows for customizable packaging designs, enhancing brand recognition.

– Professional Appearance: Improves the overall presentation and market appeal of the product.

5. Compliance:

– Regulatory Approval: Helps in adhering to legal packing regulations, including labeling requirements.

– Traceability and Batch Coding: Facilitates batch coding for better inventory management and traceability.

6. Durability and Preservation:

– Extended Shelf Life: High-quality sealing preserves freshness and extends the shelf life of gutkha.

– Durability: Packages withstand logistical handling, minimizing damage and losses during transportation.

7. Safety Features:

– Tamper Evident Packing: Ensures product integrity until it reaches the consumer.

– Child-Resistant Packaging: May include features to prevent accidental ingestion by children.

In summary, gutkha packing machines enhance productivity, ensure hygiene, reduce costs, support branding efforts, facilitate regulatory compliance, extend product shelf life, and improve packaging safety. These benefits contribute significantly to the gutkha manufacturing industry’s efficiency and market competitiveness.

List Various Types of “gutkha packing machine”

Gutkha, a form of chewing tobacco, is packaged in various forms requiring different types of packaging machines to ensure efficiency, hygiene, and product integrity. Here are some widely used types of gutkha packing machines:

### 1. Automatic Pouch Packing Machines

– Vertical Form Fill Seal (VFFS) Machines: These machines form pouches from a roll of film, fill them with gutkha, and seal them. Ideal for high-speed and high-volume packaging.

– Horizontal Form Fill Seal (HFFS) Machines: More suited for products that are better handled horizontally. These machines fill and seal pouches and provide higher filling accuracy.

### 2. Pneumatic Pouch Packing Machines

– Multi-Track Machines: Used for high-speed packing operations. They have multiple tracks for forming, filling, and sealing multiple pouches simultaneously.

– Single-Track Machines: Suitable for smaller operations; these machines are simpler and more economical yet efficient.

### 3. Mechanized Pouch Packing Machines

– Filling Machines: Specifically designed for the precise filling of gutkha into pre-formed pouches.

– Sealing Machines: Focus solely on sealing pre-filled pouches, ensuring an airtight and tamper-proof packaging.

### 4. Semi-Automatic Pouch Packing Machines

– These require a combination of manual and automatic operations. Typically used by smaller manufacturers due to their lower cost and simpler operation, though they offer lower production speeds.

### 5. Rotary Packing Machines

– Rotary Fill Seal Machines: Featuring a circular platform where pouches are indexed through various stations for filling, sealing, and coding. Efficient for moderate to high-speed packaging.

### 6. Flow Wrap Machines

– Suitable for wrapping gutkha in a continuous motion, providing a seamless and protective packaging suitable for gutkha sold in stick or rectangular formats.

### 7. Vacuum Packing Machines

– These remove air from the packaging before sealing, extending the shelf life and maintaining the freshness of gutkha.

### 8. Modified Atmosphere Packing (MAP) Machines

– Replace the air inside the packaging with a protective gas mix to enhance product life and preserve flavor.

### Conclusion

Each type of gutkha packing machine offers unique advantages depending on the production needs, volume, and packaging format required. Selections are typically based on operational efficiency, speed, and cost-effectiveness.

Custom Manufacturing Options for gutkha packing machine

When it comes to custom manufacturing options for gutkha packing machines, a range of features can be tailored to meet specific requirements. Here are the main customization aspects:

1. Machine Type and Capacity:

– Automatic, Semi-Automatic, or Manual: Depending on production scale and labor availability.

– Output Capacity: Machines can be designed for varying output levels, from small batches to high-volume production.

2. Packaging Style:

– Pouch Types: Options include pillow pouches, four-side sealed pouches, and sachets. Also, the possibility for re-sealable pouches.

– Material Compatibility: Customization for packaging materials like laminated films, aluminum foils, and biodegradable options.

3. Size and Shape Flexibility:

– Adapting the machine for different pouch sizes and product quantities.

4. Filling Mechanism:

– Enhanced by auger fillers, volumetric cups, or multi-head weighers for precise product dosing.

5. Automation Features:

– PLC Controls: For automated operations and easy parameter changes.

– Human-Machine Interface (HMI): Touchscreens for monitoring and adjustments.

– Sensors and Detectors: For real-time error detection and quality control.

6. Sealing and Cutting Options:

– Heat Sealing Bars: Different configurations to ensure secure sealing.

– Cutting Mechanism: Customizable to ensure clean and accurate cuts.

7. Quality and Compliance:

– Hygienic Design: Stainless steel construction for easy cleaning and maintenance.

– Regulatory Compliance: Machines designed to meet food safety standards and local regulations.

8. Integration Capabilities:

– Possibility to link with existing production lines and secondary packaging systems.

9. Support and Training:

– Offering comprehensive training and maintenance support tailored to ensure efficient operation.

By focusing on these customization areas, gutkha packing machines can be optimized to deliver efficiency, quality, and reliability specific to production needs.

List Quality Control and The Manufacturing Process of “gutkha packing machine”

### Quality Control and Manufacturing Process of Gutkha Packing Machine

#### Quality Control:

1. Material Inspection: High-grade stainless steel and food-grade materials are inspected for defects and compliance with standards.

2. Component Testing: Individual components, such as motors, sensors, and electronic parts, are tested for performance and reliability.

3. Assembly Verification: During assembly, checks are performed to ensure that all parts fit correctly and are installed as per the design specifications.

4. Operational Testing: The assembled machine undergoes rigorous testing under real-world operating conditions to ensure it functions efficiently and safely.

5. Calibration: Machines are calibrated to ensure accurate packaging weight and sealing precision.

6. Hygiene Check: Machines are scrutinized for ease of cleaning and ensuring they meet hygiene standards appropriate for food products.

7. Final Inspection: A comprehensive final inspection is conducted including visual, mechanical, and functional tests before packaging and dispatch.

#### Manufacturing Process:

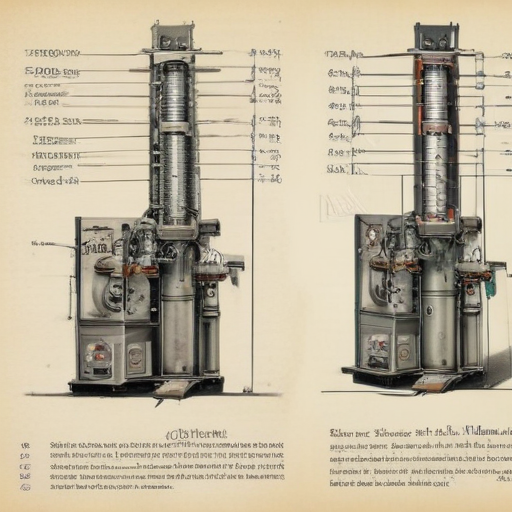

1. Design and Engineering:

– Concept Development: Initial designs and specifications are drafted based on customer requirements.

– CAD Modeling: Detailed 3D CAD models are created, highlighting the machine’s components and assembly.

2. Material Procurement:

– Raw Materials: High-quality stainless steel and other essential materials are sourced.

– Component Sourcing: Motors, sensors, control panels, and other critical components are procured from reliable suppliers.

3. Fabrication:

– Cutting and Shaping: CNC machines precision-cut the metal sheets and parts.

– Welding and Forming: Elements are welded and formed to create the machine’s frame and other structures.

4. Assembly:

– Mechanical Assembly: Assembling the frame, gears, motors, rollers, and other mechanical parts.

– Electronic Integration: Installation of control units, sensors, and wiring.

5. Testing and Calibration:

– Machines undergo several tests to check functionality and are calibrated for accuracy in packaging.

6. Finishing:

– Surface Treatment: Polishing, painting, or other surface treatments are applied for aesthetics and protection.

– Quality Control: Final quality inspections are carried out.

7. Packaging and Shipping:

– Machines are securely packed to prevent damage during transport and then dispatched to the customer.

This streamlined process ensures that the gutkha packing machine is both high-quality and reliable, meeting stringent industry standards.

How to use “gutkha packing machine”

Operating a gutkha packing machine involves several essential steps to ensure efficient and safe packaging. Here is a concise guide:

### Preparation:

1. Read the Manual: Familiarize yourself with the machine’s manual for specific instructions and safety guidelines.

2. Workspace Setup: Ensure the workspace is clean and free of any obstructions. Position the machine on a stable surface.

3. Material Ready: Have the gutkha mix and packing materials (like pouches) ready and within reach.

### Machine Setup:

4. Power On: Connect the machine to the power source and turn it on. Ensure the power supply matches the machine’s requirements.

5. Load Material: Fill the hopper with the gutkha mix. Avoid overfilling to prevent jams.

6. Adjust Settings: Set the machine parameters like pouch size, filling weight, sealing time, and temperature as per the product requirements.

### Operation:

7. Test Run: Run the machine without material for a few cycles to check its working condition and ensure all parts are moving smoothly.

8. Start Packing:

– Automatic Machines: Activate the start button. The machine will automatically fill, seal, and cut the pouches.

– Semi-Automatic Machines: Manually place the pouch, and activate the filling and sealing operations as per the machine design.

9. Monitor: Continuously monitor the machine to ensure it’s operating correctly. Look out for issues like improper sealing or incorrect fill weight.

### Post-Operation:

10. Turn Off: After packing, turn off the machine and disconnect the power supply.

11. Clean: Clean the machine thoroughly to remove any residual gutkha and prevent contamination or mechanical issues in future operations.

12. Maintenance: Regularly check and maintain parts like the hopper, sealing jaws, and cutting blades as specified in the manual.

### Safety Precautions:

– Always use personal protective equipment (PPE) like gloves and masks.

– Keep hands and tools away from moving parts during operation.

– In case of malfunctions, stop the machine immediately and perform troubleshooting as per the manual.

By following these steps, you can efficiently use a gutkha packing machine to ensure consistent and high-quality packaging.

List Properties and Terms of “gutkha packing machine”

### Properties of Gutkha Packing Machine

1. Construction Material: Typically made from stainless steel for durability and hygiene.

2. Automation: Fully automated or semi-automated options available.

3. Sealing Type: Heat sealing for airtight packs.

4. Speed: High-speed operation with adjustable settings.

5. Precision: Accurate dosing and weight control for consistent packing.

6. Versatility: Suitable for various pouch sizes and materials (LDPE, PET, Aluminum Foil).

7. User Interface: Touchscreen or button-controlled for ease of operation.

8. Output Capacity: Can range from hundreds to thousands of pouches per hour.

9. Safety Features: Emergency stop buttons, overload protection.

10. Maintenance: Easy access for cleaning and part replacement.

11. Power Consumption: Designed for energy efficiency.

### Terms Associated with Gutkha Packing Machine

1. Dosing Unit: Device that measures and dispenses the correct quantity of gutkha.

2. Feeder: Mechanism that supplies raw material (gutkha) to the machine.

3. Pouch: Packaging material used for enclosing gutkha.

4. Heat Sealer: Component that seals the pouches.

5. Conveyor: Belt system that transports pouches through different stages.

6. PLC (Programmable Logic Controller): Controls the machine operations.

7. HMI (Human Machine Interface): Interface for operators to control and monitor the machine.

8. Form-Fill-Seal Technology: Process of forming the pouch, filling it with gutkha, and sealing it shut.

9. Microcomputer Control: Ensures high precision and automation.

10. Modular Design: Allows for upgrades and custom configurations.

11. Servo Motor: Provides high precision in the packing operations.

12. Vacuum Pump: Removes air for a tight seal.

13. Batch Coding: Prints manufacturing details on each pouch.

14. Intermittent Motion: Stops and starts for precise operations.

15. Continuous Motion: Continuous operation for high-speed processes.

These machines are pivotal in the packaged gutkha industry, ensuring consistency, hygiene, and efficiency in production.

List The Evolution history of “gutkha packing machine”

The evolution history of the gutkha packing machine can be traced through several key phases, reflecting technological advancements and changes in packaging needs:

1. Manual Packaging Era (Pre-1980s):

– Initially, gutkha was manually packed, often in handmade paper or small tin containers. This method was labor-intensive and inconsistent, offering limited protection against moisture and contamination.

2. Semi-Automatic Machines (1980s-1990s):

– As demand increased, semi-automatic machines were introduced. These machines still required substantial human oversight but mechanized certain tasks, such as sealing and cutting packets.

– These machines improved consistency in packaging and increased production speed, although human error still posed a significant risk to product quality.

3. Fully Automatic Packing Machines (Late 1990s-2000s):

– The advent of fully automatic gutkha packing machines marked a significant technological leap. These machines could handle everything from filling to sealing and labeling with minimal human intervention.

– Integrated systems with Programmable Logic Controllers (PLCs) enhanced precision and efficiency, significantly reducing waste and increasing productivity.

4. Advanced Technology Integration (2010s):

– Modern gutkha packing machines began incorporating advanced technologies such as servo motors and touch-screen Human-Machine Interfaces (HMIs) for better control and diagnostics.

– Enhanced material handling capabilities allowed for better packaging materials, including multi-layer foils and customized designs that improved shelf life and product appeal.

5. Automation and IoT (2020s):

– The latest iterations include IoT-enabled systems that provide real-time monitoring and analytics. These machines can predict maintenance needs, reducing downtime and enhancing efficiency.

– Robotics and machine learning algorithms are increasingly used for quality control, ensuring that each packet meets stringent standards.

Throughout these phases, the focus has been on increasing efficiency, reducing human error, and improving product safety and consistency, reflecting the broader trends in industrial automation and packaging technology.

How to Select a Reliable gutkha packing machine

Selecting a reliable gutkha packing machine requires careful consideration of various factors to ensure efficiency, durability, and compliance with safety standards. Here’s a concise guide:

### 1. Machine Quality and Build:

– Material: Choose machines made of high-grade stainless steel to avoid corrosion and maintain hygiene.

– Durability: Look for robust construction to withstand continuous use.

### 2. Automation Level:

– Semi-Automatic vs. Fully Automatic: Determine your production needs and opt for a machine that provides the required automation level for maximum efficiency.

### 3. Speed and Capacity:

– Assess the machine’s packing speed (packs per minute) and capacity to ensure it meets your production targets.

### 4. Accuracy and Precision:

– Ensure the machine offers consistent and precise packing, which is crucial for maintaining product quality and compliance with regulations.

### 5. Ease of Operation and Maintenance:

– Choose a machine with a user-friendly interface. Easy maintenance and availability of spare parts are critical to minimize downtime.

### 6. Technological Features:

– Advanced features like touch-screen controls, automated fault detection, and remote monitoring can significantly enhance productivity.

### 7. Safety Standards and Compliance:

– Verify that the machine adheres to local and international safety standards, ensuring safe operation.

### 8. Supplier Reputation and After-Sales Service:

– Research the manufacturer’s reputation. Reliable suppliers offer excellent after-sales service, including training, troubleshooting, and spare parts availability.

### 9. Cost and Return on Investment:

– While cost is a factor, focus on the long-term return on investment. Quality machines may have higher upfront costs but offer better longevity and efficiency.

### 10. References and Reviews:

– Conduct a thorough review of customer testimonials and case studies. Request references from the supplier to gauge customer satisfaction.

### Conclusion

A reliable gutkha packing machine is a blend of quality, efficiency, technology, and support. Prioritizing these factors will help you select a machine that enhances your production line’s performance while ensuring safety and compliance.

List “gutkha packing machine” FAQ

Sure! Here are some frequently asked questions (FAQ) regarding “gutkha packing machine”:

### Gutkha Packing Machine FAQ

#### 1. What is a gutkha packing machine?

A gutkha packing machine is a specialized piece of equipment designed to automate the process of packaging gutkha, a chewed tobacco product, into sachets or pouches.

#### 2. What materials can it package?

It primarily packages gutkha, but can sometimes be adapted to package other similar substances such as supari (areca nut), pan masala, and related products.

#### 3. What are the types of gutkha packing machines?

The main types are:

– Semi-automatic machines: Require manual intervention for certain steps.

– Fully automatic machines: Handle the entire packaging process, from feeding the gutkha to sealing the pouches, without manual intervention.

#### 4. What is the packaging speed?

Packaging speed varies, typically between 30 to 100 pouches per minute, depending on the machine’s model and configuration.

#### 5. What sizes of pouches can it handle?

Most machines can be adjusted to package a range of pouch sizes, commonly from 1 gram to 10 grams.

#### 6. What are the power requirements?

Standard gutkha packing machines usually require an electrical power supply between 220V to 380V, with a power consumption of approximately 3-5 kW.

#### 7. What materials are used for construction?

High-quality stainless steel or food-grade materials are generally used to ensure hygiene and durability.

#### 8. Is it easy to operate and maintain?

Yes, most machines come with user-friendly interfaces and manuals. Routine maintenance includes regular cleaning and periodic checks of mechanical parts.

#### 9. What is the approximate cost?

Costs can range from $5,000 to $50,000 depending on the machine’s features and capacity.

#### 10. Does it comply with safety standards?

Reputable manufacturers ensure their machines comply with relevant health and safety standards, including features such as emergency stop buttons and safety guards.

#### 11. Are there customization options?

Yes, many manufacturers offer customization options to meet specific packaging needs or space constraints.

#### 12. What is the warranty period?

Warranty periods typically range from 1 to 3 years, depending on the manufacturer.

#### 13. Where can I purchase it?

Gutkha packing machines can be purchased from specialized industrial machinery suppliers, either through direct sales or online platforms.

Top 10 FAQ with answer about gutkha packing machine for Buyer Sourcing from China

Sure, here’s an FAQ section for a gutkha packing machine for buyers sourcing from China:

1. What is the primary purpose of a gutkha packing machine?

– The gutkha packing machine is used for packaging gutkha, a form of chewing tobacco, into sealed pouches for retail distribution.

2. Are Chinese gutkha packing machines reliable?

– Yes, many Chinese manufacturers offer reliable and efficient gutkha packing machines, but it’s essential to verify the supplier’s credibility and product quality.

3. What are the main features to look for in a gutkha packing machine?

– Key features include automated operation, high-speed packaging, precise dosing, low maintenance, and the ability to handle diverse pouch sizes.

4. Can the machine be customized to specific requirements?

– Many Chinese suppliers offer customization options, including alterations to pouch sizes, branding, and functionality adjustments based on the buyer’s needs.

5. What certifications should the machine have?

– Ensure the machine is CE certified and conforms to international quality standards. Compliance with ISO and other industry-specific standards is also recommended.

6. What is the average lead time for a gutkha packing machine?

– The lead time typically ranges from 30 to 60 days, depending on the machine’s complexity and the manufacturer’s production schedule.

7. How do I ensure the machine is easy to operate and maintain?

– Look for machines with user-friendly interfaces and request maintenance manuals or training sessions from the supplier.

8. Are spare parts readily available?

– Confirm with the supplier that spare parts are easily accessible and inquire about their inventory policies to avoid future disruptions.

9. What is the typical price range for these machines?

– Prices can vary widely based on features and capacity, ranging from $10,000 to $50,000. Request detailed quotes from multiple suppliers for comparison.

10. How do I handle potential shipping concerns?

– Work with experienced logistics companies and verify that the supplier follows proper export protocols. Ask about packaging details to avoid damage during transit.

These FAQs should help buyers make informed decisions when sourcing gutkha packing machines from China.