Sure, here is a list of Frequently Asked Questions (FAQs) along with their answers for sourcing a Compost Packaging Machine from Yingfeng Machinery Factory:

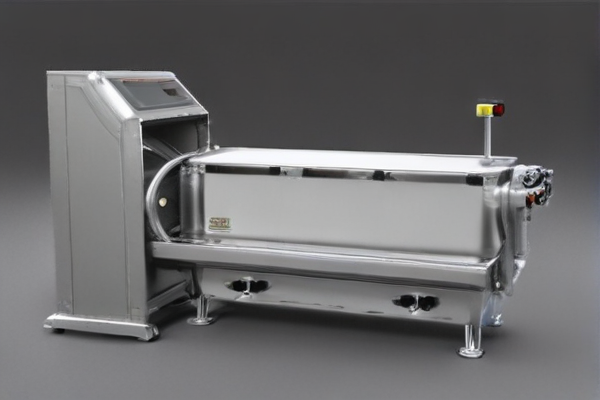

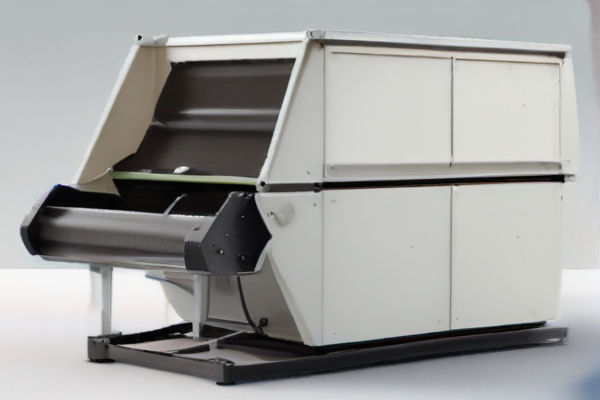

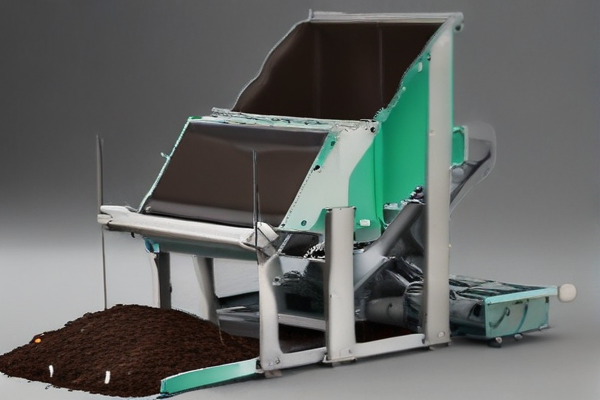

1. What types of compost packaging machines does Yingfeng Machinery offer?

Yingfeng Machinery offers a variety of compost packaging machines, including automatic bagging machines, semi-automatic packing equipment, and custom-built solutions to meet specific requirements for different types of compost materials.

2. How can I request a quote for a compost packaging machine?

To request a quote, you can visit Yingfeng Machinery’s official website and fill out the inquiry form with your details and specific requirements. Alternatively, you can contact their sales team directly via email or phone for a more personalized response.

3. What is the typical lead time for delivery?

The lead time for delivery varies depending on the specific machine model and customization needs. Standard models usually have a lead time of 4-6 weeks, while customized machines may take longer. Contact Yingfeng Machinery for the most accurate delivery estimate.

4. Does Yingfeng Machinery provide installation and training services?

Yes, Yingfeng Machinery provides comprehensive installation and training services. Their technicians can either guide you through the installation process remotely or perform an on-site installation. Training sessions are also available to ensure your team can operate the machine efficiently.

5. What kind of warranty and after-sales support is available?

Yingfeng Machinery offers a standard one-year warranty that covers manufacturing defects and parts replacements. Additionally, they provide ongoing technical support and maintenance services. Extended warranty options may also be available upon request.

6. Can the machine be customized to fit specific packaging requirements?

Absolutely. Yingfeng Machinery specializes in creating customized packaging solutions to suit various compost packaging needs. You can discuss your specific requirements with their engineering team to design a machine that accurately fits your operational demands.

7. What payment methods are accepted?

Yingfeng Machinery accepts multiple payment methods, including bank transfer (T/T), letter of credit (L/C), and other commonly accepted international payment options. It’s best to discuss payment terms directly with their sales team.

8. Is it possible to visit the factory for a machine demonstration?

Yes, Yingfeng Machinery welcomes potential customers to visit their factory. You can schedule a visit through their website or by contacting their sales team. Factory visits allow you to see the machinery in action and discuss any specific requirements in detail.

9. How energy-efficient are Yingfeng’s compost packaging machines?

Yingfeng Machinery designs their compost packaging machines to be energy-efficient, reducing operational costs and environmental impact. Specific energy consumption details can be provided based on the machine model you are interested in.

10. Are spare parts readily available?

Yes, spare parts for Yingfeng Machinery’s compost packaging machines are readily available. They maintain an inventory of essential parts to ensure quick replacements and minimize downtime.

These FAQs provide a basic understanding of sourcing compost packaging machines from Yingfeng Machinery Factory. For more detailed inquiries, it is recommended to contact their customer service or sales representatives directly.