List Technical Parameters of “stretch hood wrapping machine”

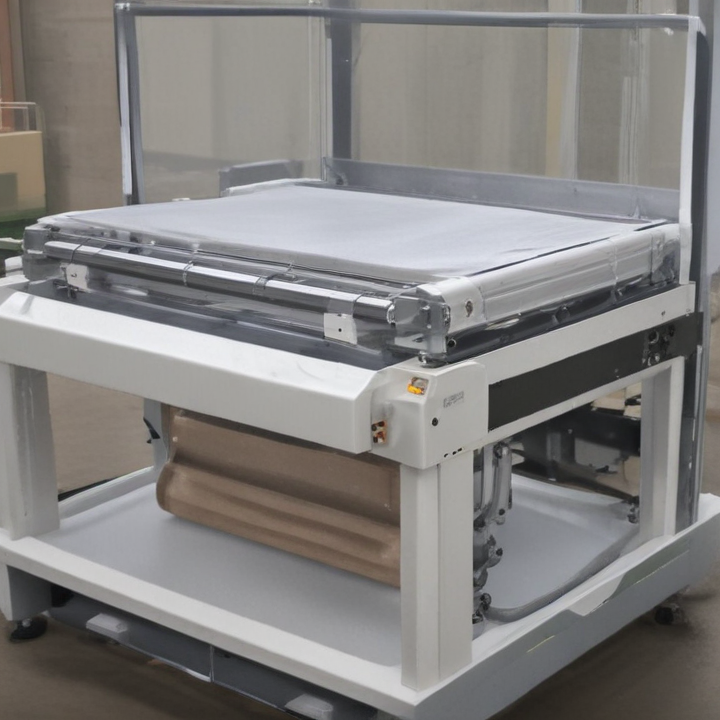

A stretch hood wrapping machine is used for securing loads and providing stability during transportation. It does so by drawing a pre-stretched plastic film over a palletized load. Key technical parameters of a stretch hood wrapping machine include:

1. Wrapping Speed: Typically measured in loads per hour, the speed determines the efficiency of the machine. Standard machines can wrap anywhere from 30 to 150 loads per hour.

2. Film Type and Thickness: Compatibility with various film types (e.g., polyethylene) and thicknesses, usually ranging from 30 to 150 microns, is crucial.

3. Control System: Advanced machines feature user-friendly interfaces, often with touchscreen controls, and programmable logic controllers (PLC) for precision and customization.

4. Load Dimensions: Maximum and minimum load dimensions (width, length, height) that the machine can handle. Common ranges are:

– Width: 800-1,200 mm

– Length: 1,000-1,200 mm

– Height: up to 2,400 mm

5. Load Weight: Maximum load weight capacity, which generally ranges from 1,000 to 2,500 kg.

6. Power Requirements: Voltage and power specifications, typically around 230-480V and 50-60Hz with different power consumption levels based on the machine’s size and capabilities.

7. Film Stretch and Retraction Rate: The degree to which the film is stretched during application and its subsequent rate of retraction, typically between 200-300%.

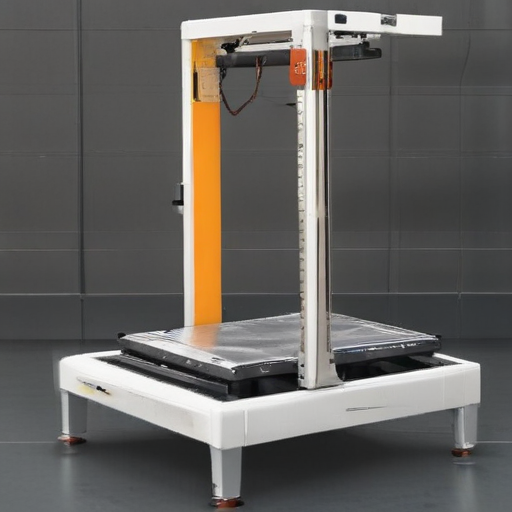

8. Machine Dimensions and Weight: Overall footprint and weight of the machine itself, which vary depending on the design, but generally remain manageable for integration into existing production lines.

9. Environmental Ratings: Temperature and humidity ranges within which the machine operates efficiently. Most machines function well between 0°C and 40°C.

10. Safety Features: Includes guards, emergency stop buttons, and adherence to safety standards like CE or UL.

11. Maintenance Requirements: Frequency and ease of maintenance, typically involving routine checks and part replacements to ensure longevity and functionality.

Understanding these parameters ensures efficient matching of a stretch hood wrapping machine to operational needs.

List Product features of “stretch hood wrapping machine”

Sure, here are the concise product features of a “stretch hood wrapping machine”:

1. Automated Operation: Reduces manual labor and increases operational efficiency through automated wrapping processes.

2. Versatile Application: Suitable for various pallet sizes and configurations, including irregularly shaped loads.

3. High Throughput: Capable of wrapping multiple pallets per hour, ensuring quick and efficient packaging.

4. Secure Wrapping: Provides high-load stability and protection with tightly secured film, minimizing movement during transportation.

5. Adjustable Film Tension: Allows customization of film tension to accommodate different load types ensuring optimum wrap quality.

6. Energy Efficient: Consumes less power compared to heat-shrink packaging methods, promoting lower operational costs.

7. Film Saving: Innovative film stretching mechanisms ensure optimal material use, reducing waste.

8. User-Friendly Interface: Typically equipped with an intuitive control panel for easy operation and monitoring.

9. Durable Construction: Built with robust materials to ensure longevity and reliable performance even under heavy-duty use.

10. Safety Features: Incorporates multiple safety mechanisms including emergency stops and safety guards to protect operators.

11. Low Maintenance: Engineered for minimal maintenance requirements, ensuring uninterrupted operation and reduced downtime.

12. Consistent Performance: Delivers uniform wrapping quality across all packages, enhancing overall packaging standard.

13. Environmentally Friendly: Reduces plastic film usage significantly compared to traditional methods, supporting eco-friendly practices.

14. Customizable Options: Offers a range of customization such as film type, color, and thickness to meet specific packaging needs.

15. Integrable with Existing Systems: Easily integrated into existing production lines for seamless operation and increased productivity.

16. Remote Monitoring and Diagnostics: Some models offer remote access for monitoring performance and troubleshooting, reducing the need for on-site technical support.

These features collectively enhance packaging efficiency, product protection, and cost-effectiveness for businesses using stretch hood wrapping machines.

List Application of “stretch hood wrapping machine”

A stretch hood wrapping machine is employed in various industries to secure and protect palletized goods during transportation and storage. Here are its key applications:

1. Logistics and Warehousing: Stretch hood wrapping machines are extensively used in warehouses and distribution centers. They ensure pallets are tightly wrapped, minimizing the risk of product displacement and damage during transit. This enhances load stability and safety.

2. Food and Beverage Industry: These machines offer excellent protection for perishable products. They maintain the freshness of food items and provide a tamper-evident seal, which is crucial for consumer safety.

3. Chemical and Pharmaceutical Industries: These sectors often deal with volatile and sensitive materials. Stretch hood wrapping provides an airtight seal, protecting products from environmental factors such as moisture and contaminants, and ensuring compliance with strict regulatory standards.

4. Building Materials: Products like bricks, tiles, cement bags, and other bulky construction materials are efficiently wrapped using stretch hood machines. This keeps dust, moisture, and debris out, preserving the integrity of the building materials.

5. Consumer Goods: Electronics, household items, and other consumer goods are wrapped to guard against damage from handling and environmental factors. The clear film allows easy identification and barcode scanning.

6. Agriculture: Agricultural products like seeds, fertilizers, and grains are securely wrapped to prevent spoilage and contamination. This ensures long-term storage stability and integrity during seasonal changes.

7. Automotive and Parts: The automotive industry benefits from stretch hood wrapping to protect components and spare parts from dust, moisture, and mechanical damage, ensuring they arrive at the assembly line in pristine condition.

8. Textiles and Paper Industries: Rolls of fabrics, paper, and corrugated materials are protected from dust and moisture, keeping them clean and dry until used in manufacturing or retail.

By offering robust product protection, enhanced load stability, and improved handling efficiency, stretch hood wrapping machines serve as essential tools across diverse industrial applications.

List Various Types of “stretch hood wrapping machine”

Certainly! Stretch hood wrapping machines are advanced packaging systems used to secure and protect palletized goods by applying a stretchable plastic hood. Here are various types:

1. Fully Automatic Stretch Hood Wrapping Machines:

– High-Speed Models: Designed for large-scale operations, capable of handling high throughput with minimal downtime.

– Standard Models: Suitable for mid-sized operations, balancing efficiency and cost.

2. Semi-Automatic Stretch Hood Wrapping Machines:

– These require some human intervention for loading and positioning but automate the wrapping process itself.

3. Compact Stretch Hood Wrapping Machines:

– Ideal for smaller facilities with limited floor space. They offer basic functionalities, ensuring compactness without compromising on effectiveness.

4. Rotary Arm Stretch Hood Wrapping Machines:

– Utilizes a rotating arm to apply the stretch hood, suitable for unstable or lightweight pallet loads.

5. Turntable Stretch Hood Wrapping Machines:

– The pallet is placed on a turntable that rotates while the stretch hood is applied, ensuring even distribution of the wrapping material.

6. Inline Stretch Hood Wrapping Machines:

– Integrates seamlessly with existing production lines, providing continuous, high-volume wrapping without interruption.

7. Customized Stretch Hood Wrapping Machines:

– Tailor-made to meet specific requirements, including unique pallet sizes, shapes, or special wrapping materials.

8. Mobile Stretch Hood Wrapping Machines:

– Portable units that can be moved to different locations within a facility, offering flexibility for wrapping at various points.

9. Heavy-Duty Stretch Hood Wrapping Machines:

– Engineered for robust use in demanding environments, capable of handling heavy and large pallet loads.

Each type serves different needs, from high-speed operations to compact or specialized applications, providing versatile solutions for securing palletized goods efficiently and effectively.

Custom Manufacturing Options for stretch hood wrapping machine

When procuring a stretch hood wrapping machine, custom manufacturing options can significantly enhance operational efficiency and align the equipment with specific business needs. Key customization choices include:

1. Size and Capacity: Machines can be tailored to accommodate various pallet sizes, weights, and shapes, ensuring a perfect fit for your production requirements.

2. Film Compatibility: Customization can be done to handle different types of stretch films, including those with varying thicknesses, pre-stretched films, and eco-friendly options.

3. Control Systems: Advanced programmable logic controllers (PLCs) and human-machine interfaces (HMIs) can be customized to offer intuitive controls and integration with existing warehouse management systems (WMS) for enhanced efficiency.

4. Speed and Output: Adjustments in the mechanical design can optimize wrapping speeds and throughput, accommodating high-speed production lines or specialized wrapping requirements.

5. Safety Features: Custom safety solutions, such as protective guards, emergency stop buttons, and interlock systems, can be added to meet regulatory standards and ensure operator safety.

6. Automation Integration: Custom options might include full integration with automated guided vehicles (AGVs) and conveyor systems for seamless, end-to-end automation.

7. Environmental Adaptations: Machines can be outfitted with climate-resistant coatings and components to operate in harsh environments, such as cold storage or high-humidity areas.

8. Custom Tooling and Add-ons: Additional features like corner applicators, top sheet dispensers, and in-line weighing systems can be integrated to enhance the versatility of the machine.

9. Ergonomics and Accessibility: Customizing the machine’s height, control placement, and accessibility features can improve operator comfort and reduce fatigue.

10. Aesthetic and Branding: Custom colors, branding, and design modifications can align the machine with corporate identity guidelines.

By leveraging these customization options, businesses can ensure their stretch hood wrapping machines are perfectly suited to their unique operational needs, driving productivity and ensuring long-term value.

List Quality Control and The Manufacturing Process of “stretch hood wrapping machine”

### Quality Control

1. Component Inspection:

– Incoming Materials: All raw materials and components, such as motors, sensors, and frames, are inspected for quality and specifications.

– Supplier Verification: Regular audits of suppliers ensure they meet quality standards.

2. Assembly Line Checks:

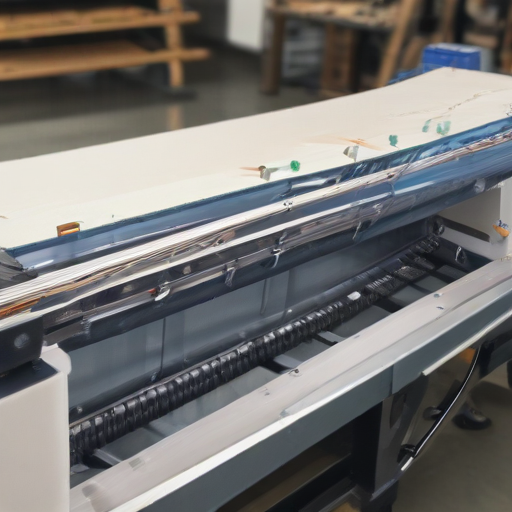

– Sub-Assemblies: Critical sub-assemblies like tensioning systems, sealing units, and control panels are tested individually.

– Process Audits: In-process inspections are conducted to ensure adherence to assembly protocols.

3. Functional Testing:

– Preliminary Testing: Assembled machines undergo preliminary tests to check basic functionality.

– Final Testing: Comprehensive testing includes wrapping performance, load stability, and system integration checks.

4. Calibration and Validation:

– Equipment Calibration: Measuring instruments and control systems are calibrated to ensure precision.

– Validation: Machines are validated against operational and safety benchmarks.

5. Quality Documentation:

– Records: Inspection and testing results are documented for traceability.

– Certification: Machines are certified for compliance with industry standards.

### Manufacturing Process

1. Design and Engineering:

– Concept Design: Initial designs are created based on customer requirements and industry standards.

– Prototyping: Prototypes are developed and tested for feasibility and performance.

2. Material Procurement:

– Sourcing: High-quality materials and components are procured from verified suppliers.

– Inventory Management: Efficient inventory systems ensure timely availability of components.

3. Fabrication and Machining:

– Metal Fabrication: Frames and structural components are cut, welded, and machined to specifications.

– Precision Machining: Critical parts are CNC machined for accuracy.

4. Assembly:

– Sub-Assembly: Key components like motors, rollers, and control units are assembled.

– Main Assembly: Sub-assemblies are integrated into the main machine framework.

5. Wiring and Control Systems:

– Electrical Wiring: Machines are wired for control and power distribution.

– Programming: Control systems are programmed and configured for specific operations.

6. Quality Testing:

– Initial Testing: Basic functionality and safety tests are conducted.

– Final Testing: Comprehensive tests ensure machine performance and compliance.

7. Packaging and Shipping:

– Inspection: Final inspection is performed before packaging.

– Packaging: Machines are securely packaged to prevent damage during transit.

– Shipping: Packaged machines are shipped to customers with required documentation.

By following stringent quality control measures and a structured manufacturing process, manufacturers ensure the stretch hood wrapping machine meets high standards of performance and reliability.

How to use “stretch hood wrapping machine”

Using a stretch hood wrapping machine efficiently is vital for securing pallet loads and protecting goods during transportation and storage. Here’s a step-by-step guide to using a stretch hood wrapping machine:

1. Set Up the Machine:

– Ensure the machine is properly installed and connected to a power source.

– Check that the stretch hood film is correctly loaded on the machine. The film roll should be placed on the designated holder and threaded according to the manufacturer’s instructions.

2. Adjust Settings:

– Configure the machine settings based on the size and type of the load. This includes adjusting parameters like the height of the pallet, film tension, and wrapping speed.

– Select the appropriate wrapping mode (e.g., full-hood, support, or vertical wrap) depending on the application.

3. Load the Pallet:

– Position the palletized goods on the machine’s loading platform. Ensure that the load is stable and centered to prevent any shifting during the wrapping process.

4. Start the Wrapping Process:

– Initiate the wrapping cycle either manually or through an automated system.

– The machine will measure the height of the load and dispense the film accordingly.

– The stretch hood film will be drawn down over the pallet, shrinking and securing the load tightly.

5. Monitoring and Adjustment:

– Observe the wrapping process to ensure the film is applied evenly and without tears or holes.

– Make any necessary adjustments to tension or speed settings if the film is not adhering properly.

6. Finalizing:

– Once the cycle is complete, the machine will cut the film automatically, and the wrapped pallet can be removed.

– Inspect the wrapped pallet to ensure the film is tight and provides adequate protection.

7. Maintenance:

– Regularly check and maintain the machine to ensure optimal performance. This includes cleaning sensors, checking film tensioners, and lubricating moving parts.

By following these steps, you can effectively use a stretch hood wrapping machine to secure and protect your pallet loads.

List Properties and Terms of “stretch hood wrapping machine”

A stretch hood wrapping machine is a versatile and advanced piece of packaging equipment designed to secure and protect palletized loads. It provides a secure, stable, and tamper-evident containment for various products through the application of a stretchable film hood. Below are the properties and terms associated with stretch hood wrapping machines:

### Properties:

1. High Stretchability: Uses stretchable plastic film that can elongate without tearing, ensuring tight wrapping.

2. Protection: Offers dust, dirt, and moisture protection, thereby preserving product integrity.

3. Versatile Application: Suitable for different pallet sizes, shapes, and types of products.

4. Efficiency: High-speed operation, capable of wrapping multiple pallets per hour.

5. Stability: Provides load stability during transport and storage due to the tight fit.

6. Cost-Effectiveness: Reduces film usage compared to shrink wrap, saving material costs.

7. Easy Integration: Can be integrated into existing production lines.

8. Automation: Features automated film detection, cutting, and sealing for minimal manual intervention.

9. Safety: Includes safety features such as emergency stops, interlocks, and guarding.

10. Environmental: Uses recyclable and eco-friendly film materials.

### Terms:

1. Film Roll: The roll of stretchable polyethylene film used in the machine.

2. Pre-Stretch Ratio: The extent to which film can be stretched before application. Higher ratios mean more coverage with less material.

3. Elastic Recovery: The film’s ability to return to its original shape after stretching.

4. Film Thickness (Micron/Gauge): Determines the durability and strength of the wrapping material.

5. Load Containment: The ability of the film to maintain a secure and stable load during transit.

6. Hooding: The process of creating a ‘hood’ shape that envelopes the pallet.

7. Wrapping Speed: The number of pallets the machine can wrap per hour.

8. Cycle Time: The time taken to complete one full wrapping cycle.

9. Load Profile: Specific dimensions and weight of the palletized load.

10. Control Panel: Interface for operating and programming the machine settings.

Stretch hood wrapping machines offer an efficient and effective solution for securing palletized loads, ensuring product safety, and optimizing material usage.

List The Evolution history of “stretch hood wrapping machine”

The concept and development of stretch hood wrapping machines has evolved significantly over the years, driven by advancements in materials technology and automation.

1. 1980s – Initial Concept: The inception of pallet wrapping primarily involved stretch wrap film applied using semi-automatic machines. While effective, this method required manual intervention and did not always offer comprehensive protection.

2. Early 1990s – Basic Automation: The introduction of more automated stretch wrap machines began. These machines reduced the amount of manual labor required but were still largely focused on conventional stretch wrapping techniques around the pallet.

3. Mid-to-Late 1990s – Emergence of Stretch Hooding: As technologies advanced, the concept of stretch hooding emerged. This innovation involved elastic film hoods that could be stretched and applied over the entirety of a pallet load, providing better stability and protection against environmental factors. Initial machines were relatively simple and aimed at industries dealing with uniform pallet shipments.

4. Early 2000s – Technological Innovations: Improved materials with greater elasticity and strength, combined with more sophisticated automation technologies, significantly enhanced the performance and reliability of stretch hood wrapping machines. These machines became capable of handling varying load sizes and shapes more efficiently.

5. 2010s – Advanced Automation and Efficiency: The integration of IoT (Internet of Things) and more advanced sensors allowed for further optimization. Machines now offered real-time monitoring, predictive maintenance, and integration with broader supply chain management systems.

6. 2020s – Sustainability and Smart Technologies: Recent developments have focused on sustainability, with the use of recyclable and biodegradable films. Enhanced machine learning algorithms and AI have enabled smarter, more adaptive machines that can dynamically adjust wrapping parameters for optimal performance and material usage.

Today, stretch hood wrapping machines are a vital component in the logistics and packaging industry, ensuring goods are securely protected during transit while also embracing efficiency and environmental responsibility.

How to Select a Reliable stretch hood wrapping machine

Selecting a reliable stretch hood wrapping machine is crucial for ensuring efficient packaging and product protection. Here are some key factors to consider:

1. Machine Compatibility:

– Product Dimensions: Ensure the machine can handle the size and shape of your products.

– Material Compatibility: Confirm that the machine is compatible with the type of stretch hood film you plan to use.

2. Quality and Durability:

– Build Quality: Look for machines made from robust materials for longevity.

– Brand Reputation: Opt for well-known brands with positive reviews and reliable service records.

3. Performance:

– Speed: Check the machine’s wrapping speed to ensure it meets your production requirements.

– Consistency: Ensure it provides uniform wrapping without compromising on stability.

4. Automation and Features:

– Automation Level: Evaluate whether a semi-automatic or fully automatic machine suits your operational needs.

– Advanced Features: Look for features like adjustable tension control, multiple wrapping modes, and easy film changeover.

5. Ease of Use and Maintenance:

– User Interface: A user-friendly interface simplifies operation and reduces training time.

– Maintenance: Choose machines known for easy maintenance and minimal downtime.

6. Cost and Return on Investment:

– Initial Cost: Balance between upfront cost and the value it offers.

– Operational Costs: Consider energy efficiency and film consumption.

– Return on Investment (ROI): Factor in productivity gains and potential cost savings.

7. After-Sales Support:

– Customer Service: Ensure the manufacturer offers robust after-sales support including training, troubleshooting, and parts availability.

– Warranty: A solid warranty can provide peace of mind and protect against defects.

8. Safety Features:

– Protective Mechanisms: Ensure it includes safety features to protect operators and prevent accidents.

Research thoroughly, compare options, and perhaps seek recommendations or case studies from industry peers to find a reliable stretch hood wrapping machine that meets your needs.

List “stretch hood wrapping machine” FAQ

Stretch Hood Wrapping Machine FAQ

1. What is a stretch hood wrapping machine?

A stretch hood wrapping machine is an automated system used to secure and stabilize palletized loads using a continuous tubular film. Unlike stretch wrap or shrink wrap, stretch hood film forms a hood over the load, providing enhanced protection and stability.

2. How does it work?

The machine draws a piece of tubular stretch film from a roll, stretches it to fit over the palletized load, and then releases it. The elastic properties of the film ensure it snugly conforms to the shape of the load, offering tight containment.

3. What are the benefits of using a stretch hood machine?

– Enhanced Load Stability: The film provides excellent holding force.

– Weather Protection: Offers superior protection against dust, moisture, and UV rays.

– Cost Efficiency: Reduces the amount of film needed compared to other wrapping methods.

– Safety: Minimizes the risk of load shifting during transport.

– Automation: Increases productivity and reduces labor costs.

4. What types of businesses can benefit?

Industries such as food and beverage, construction materials, chemicals, and logistics can greatly benefit from using a stretch hood wrapping machine for their palletized goods.

5. Is it compatible with different load sizes and shapes?

Yes, stretch hood machines are highly versatile and can accommodate a variety of load sizes, shapes, and pallet configurations.

6. How fast can it operate?

Depending on the model, a stretch hood machine can wrap between 150 to 250 pallets per hour, offering significant time savings in high-volume operations.

7. What maintenance is required?

Regular maintenance includes routine inspections, cleaning, and lubrication of moving parts. It’s also essential to check and replace worn-out components like the cutting device and film guides.

8. What types of film are used?

High-performance polyethylene (PE) stretch hood films are most commonly used, offering excellent stretch and cling properties.

9. Can it be integrated into an existing production line?

Yes, most stretch hood wrapping machines can be seamlessly integrated into existing production lines with minimal disruption.

10. Are there options for customization?

Many manufacturers offer customizable options to meet specific requirements, including different film widths, load heights, and additional features like print registration for branded packaging.

Top 10 FAQ with answer about stretch hood wrapping machine for Buyer Sourcing from China

1. What is a stretch hood wrapping machine?

– A stretch hood wrapping machine is an automated packaging device used to secure loads on pallets using a stretchable plastic film. The hood-like film protects goods during transportation and storage.

2. Why should I consider sourcing from China?

– China provides cost-effective manufacturing, advanced technology, a wide variety of models, and robust supply chains. Additionally, many Chinese suppliers offer customization and after-sales support.

3. How do I ensure the quality of the stretch hood wrapping machine?

– Ensure quality by checking certifications like ISO, CE, and conducting factory audits. Requesting product samples, reading customer reviews, and working with established suppliers also help.

4. What are the key features to look for?

– Look for adjustable tension control, high-speed wrapping capabilities, user-friendly interface, compatibility with various pallet sizes, and energy efficiency. Safety features are also crucial.

5. Does the machine require special maintenance?

– Regular maintenance includes checking mechanical parts, lubrication, cleaning sensors, and software updates. Many manufacturers provide a maintenance schedule and guidelines.

6. Can these machines be customized?

– Yes, many Chinese manufacturers offer customization options to cater to specific needs, such as film type, color, machine dimensions, and additional features.

7. What is the typical lead time for delivery?

– Lead times vary depending on the manufacturer but typically range from 4 to 8 weeks for production. Shipping time depends on the chosen method (air, sea, rail).

8. What shipping options are available?

– Options include air freight for faster delivery or sea freight for cost-effective bulk shipping. Consult your supplier for the best shipping method based on urgency and budget.

9. How do I handle import duties and documentation?

– Work with an experienced freight forwarder or customs broker. Ensure all necessary documents, such as the commercial invoice, bill of lading, and certificate of origin, are in order.

10. What after-sales support is offered?

– Reliable suppliers provide after-sales support, including installation guidance, training, spare parts, and technical assistance. Verify the support services included in the contract.

By addressing these frequently asked questions, potential buyers can make informed decisions when sourcing stretch hood wrapping machines from China.