Top 10 innovation in packaging in China introduce,list main products and website if have

1. Smart Packaging

– Main Products: QR codes, NFC tags

– Website: JD.com, Alibaba.com

2. Sustainable Packaging

– Main Products: Biodegradable packaging, recyclable materials

– Website: Blueland.cn

3. Edible Packaging

– Main Products: Edible films, coatings

– Website: MoguJie.com

4. Active Packaging

– Main Products: Oxygen absorbers, moisture control packs

– Website: Scio-360.com

5. Antimicrobial Packaging

– Main Products: Antimicrobial films, coatings

– Website: Sino-Pack.com

6. 3D Printed Packaging

– Main Products: Customizable packaging shapes, structures

– Website: Made-in-China.com

7. Interactive Packaging

– Main Products: Augmented reality (AR) labels, smart apps

– Website: JD.com

8. Lightweight Packaging

– Main Products: Thin-walled containers, reduced material usage

– Website: Suntech-packing.com

9. Temperature-Sensitive Packaging

– Main Products: Insulated containers, temperature indicators

– Website: Qxyz.com

10. Flexible Packaging

– Main Products: Pouches, films

– Website: ShanghaiDaren.com

These innovations leverage China’s advanced technological capabilities and its commitment to sustainability, impacting various industries from food and beverage to cosmetics and electronics.

Types of innovation in packaging

Packaging innovation plays a crucial role in enhancing product appeal, functionality, sustainability, and branding. Here are key types of innovation in packaging:

1. Sustainable Packaging:

– Focuses on reducing environmental impact. Utilizes recyclable, biodegradable, or compostable materials. Reduces packaging volume and encourages the use of renewable resources.

2. Smart Packaging:

– Incorporates technology such as QR codes, RFID tags, or NFC chips. Provides consumers with additional information like product origin, authenticity, and interactive experiences. Can also monitor freshness or temperature conditions of the product.

3. Convenience Packaging:

– Designed to simplify the consumer experience. Features easy-open/close mechanisms, portion control, or resealable packaging. Lightweight and portable options also fall under this category.

4. Aesthetic and Enhanced Brand Packaging:

– Focuses on visual appeal and brand differentiation through innovative designs, textures, and colors. Customizable and limited-edition packaging can create a sense of exclusivity and attract customers.

5. Functionality-focused Packaging:

– Enhances product usability and protection. Examples include tamper-evident seals, moisture barriers, and shock-absorbent materials. Multifunctional designs like packages that transform into dispensers or serving trays also count.

6. Minimalist Packaging:

– Emphasizes simplicity and efficiency. Uses fewer materials and incorporates clean design principles. Often associated with luxury brands and eco-friendly products.

7. Inclusive Packaging:

– Aims to be user-friendly for all demographics, including the elderly and disabled. Uses larger fonts, clearer instructions, and adaptive designs to accommodate various needs.

8. Edible Packaging:

– Innovative and eco-friendly, involves packaging made from edible materials. An example is packaging made from seaweed or other food-grade components, which reduces waste as the packaging can be consumed alongside the product.

By integrating these innovative approaches, brands can enhance user experience, promote sustainability, and stand out in a competitive market.

Pros and Cons of Using innovation in packaging

Pros:

1. Sustainability: Innovative packaging can utilize eco-friendly materials, reducing the environmental impact. Biodegradable and recyclable options decrease waste and carbon footprint.

2. Brand Differentiation: Unique packaging designs help brands stand out on the shelves and can create a memorable customer experience. This can enhance brand loyalty and attract new customers.

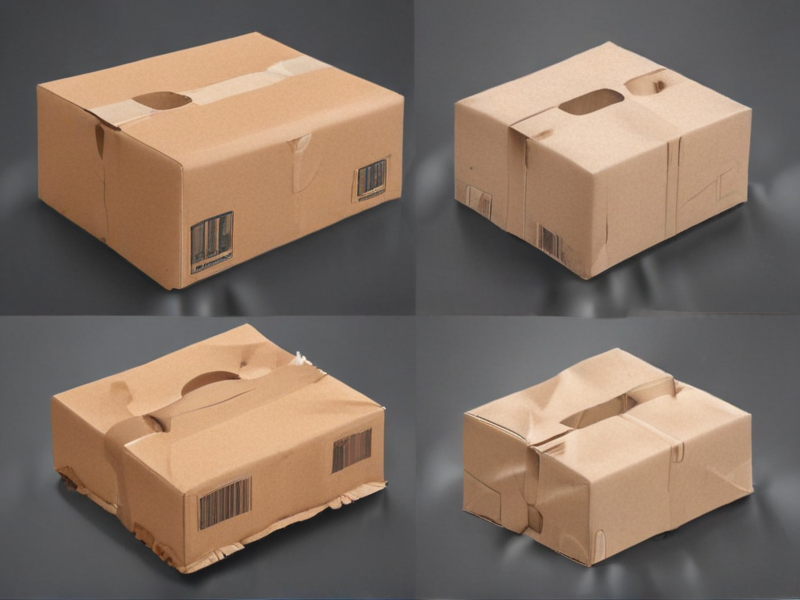

3. Product Protection: Advanced packaging solutions can offer better protection against damage, contamination, and spoilage. This is particularly crucial for perishable and sensitive products.

4. Cost Efficiency: Innovative packaging materials and designs can reduce shipping costs by being lighter or more compact. Automation in packaging can also lower labor costs and increase efficiency.

5. Regulatory Compliance: New packaging can meet evolving regulatory requirements related to safety, labeling, and environmental standards, thus avoiding legal issues and fines.

6. Convenience: User-friendly packaging designs can improve consumer convenience, enhancing the overall customer experience. Resealable, easy-to-open packages, for example, add value.

Cons:

1. Cost of Development: Innovation often requires significant investment in research, development, and production. This can be a financial burden, particularly for smaller companies.

2. Implementation Time: The time required to research, develop, and implement new packaging solutions can be lengthy, possibly delaying product launches.

3. Risk of Failure: Not all innovative solutions succeed in the market. There is a risk that consumers may not accept or prefer new packaging formats, leading to wasted investment.

4. Complexity: Advanced packaging might require sophisticated manufacturing processes and technologies, increasing operational complexity and the potential for technical issues.

5. Supply Chain Adjustments: Introducing new packaging materials or designs may necessitate changes in the supply chain, including sourcing, storage, and transportation, which can be disruptive.

6. Consumer Adaptation: Consumers may need time to adapt to new packaging, especially if it changes their user habits or requires them to learn new ways to handle the product.

In conclusion, while innovative packaging offers significant benefits, including sustainability, brand differentiation, and efficiency, it also poses challenges such as higher development costs, implementation time, and potential market risks. Balancing these factors is essential for successful adoption.

innovation in packaging Reference Specifications (varies for different product)

Innovation in packaging has revolutionized how products are protected, presented, and perceived, catering to varied reference specifications unique to each product type. One key aspect of innovative packaging is customization, ensuring that each design meets the specific needs of the product it encases.

1. Sustainability: Environmentally friendly materials are at the forefront, with biodegradable, recyclable, or reusable packaging gaining traction. Brands are innovating with materials like plant-based plastics, mushroom packaging, and recycled paper to reduce their ecological footprint.

2. Functionality: Advanced features such as resealable zippers, easy-open tabs, and compartmentalized designs add convenience for users. For perishable goods, active packaging incorporating moisture absorbers or antimicrobial agents extends shelf life and maintains freshness.

3. Protection: For sensitive electronics or fragile items, shock-absorbing foams, air cushions, and tamper-evident seals ensure safe transit and maintain integrity. Anti-static packages are crucial for semiconductor and electronics industries to prevent damage from static electricity.

4. Smart Packaging: Integration of QR codes, RFID tags, and NFC chips offers interactive experiences and traceability, enhancing security and customer engagement. Smart labels can monitor temperature and humidity, providing data on product condition and ensuring quality is maintained.

5. Visual and Structural Design: Eye-catching graphics and unique structural designs improve shelf appeal and brand recognition. High-quality printing techniques and 3D textures add to the sensory experience, enticing consumers and conveying premium quality.

6. Ergonomics: Packaging that is easy to handle, lightweight, and tailored for comfort enhances user experience, especially for elderly and disabled customers.

7. Customization and Personalization: Digital printing allows for tailored designs, personalized messages, and limited edition runs, fostering a personal connection between brands and consumers.

Each of these innovations aligns with different product specifications, ensuring that the packaging not only protects but also enhances the overall consumer experience.

Applications of innovation in packaging

Innovation in packaging has ushered in a range of applications that enhance functionality, sustainability, and consumer engagement across various industries. Here are key examples:

1. Sustainable Packaging: Brands are increasingly using biodegradable, compostable, and recyclable materials. Innovations such as plant-based plastics, mushroom-based packaging, and edible packaging films reduce environmental impact.

2. Smart Packaging: Integration of technology, such as QR codes, NFC tags, and RFID, allows for improved supply chain tracking, anti-counterfeiting measures, and enhanced customer interaction. These technologies enable consumers to access product information, verify authenticity, and engage with brands through their smartphones.

3. Active Packaging: This type of packaging interacts with the contents to extend shelf life and maintain product freshness. Oxygen scavengers, moisture absorbers, and antimicrobial layers are embedded to preserve perishable items like food and pharmaceuticals.

4. Enhanced Convenience: Packaging designs that prioritize user-friendliness, such as resealable bags, single-serve options, and easy-open features, cater to busy lifestyles and improve usability.

5. Eco-Design: Lightweighting, or reducing the amount of material used in packaging, helps minimize waste and transportation costs. Nestable and collapsible designs also save storage space and reduce carbon footprints.

6. Personalization: Advances in digital printing and customization technology allow brands to create personalized packaging for consumers. This can lead to higher consumer engagement and brand loyalty, as seen with campaigns like Coca-Cola’s personalized bottles.

7. Innovative Shapes and Textures: Unique designs and tactile elements can make products stand out on the shelf and improve the user experience. Ergonomically designed packaging also ensures better handling and product safety.

By leveraging these innovations, companies can not only improve their products’ marketability but also contribute to global sustainability efforts and meet evolving consumer demands.

Material of innovation in packaging

The push for sustainability has driven remarkable innovations in packaging materials. Among these, several standout options are gaining traction due to their environmental benefits, versatility, and performance.

1. Biodegradable Plastics: Derived from natural sources such as cornstarch or sugarcane, biodegradable plastics like polylactic acid (PLA) are designed to break down more quickly than traditional plastics. Though they still require industrial composting facilities, they significantly reduce long-term environmental impact.

2. Mushroom Packaging: Created from agricultural waste and mycelium (the root structure of mushrooms), this material is entirely compostable and offers a sustainable alternative for packaging fragile items. It grows in a matter of days and decomposes in natural environments without leaving toxic residues.

3. Seaweed-Based Packaging: Leveraging the abundant and rapidly renewable properties of seaweed, companies are producing packaging solutions like edible films and sachets. Seaweed packaging is biodegradable and dissolvable, making it ideal for reducing plastic waste in the food industry.

4. Recycled Paper and Cardboard: While not new, innovations in recycling processes have greatly improved the viability of recycled paper and cardboard. Advanced techniques produce high-quality, durable packaging options that are fully recyclable, often reducing the need for virgin materials.

5. Plantable Packaging: This innovative approach embeds seeds into biodegradable packaging materials. Once the packaging is no longer needed, it can be planted to grow herbs, flowers, or vegetables, offering a unique, eco-friendly lifecycle.

6. Bioplastic Films and Bags: Made from renewable plant materials, bioplastic films and bags offer a flexible, lightweight option for food and product packaging. They decompose more readily than petroleum-based plastics, aligning with growing regulatory pressures for sustainable solutions.

These innovative materials not only address the critical environmental issues posed by conventional plastics but also offer practical and scalable alternatives for industries committed to sustainability.

Quality Testing Methods for innovation in packaging and how to control the quality

Quality testing methods for innovative packaging are crucial for ensuring product safety, functionality, and consumer satisfaction. Here’s an overview of methods and control mechanisms:

1. Material Testing:

– Tensile and Compression Testing: Assesses the material’s strength and resistance to deformation.

– Barrier Testing: Checks the material’s ability to prevent moisture, oxygen, and other gases from penetrating.

– Chemical Resistance: Ensures the material doesn’t react adversely with the product or environment.

2. Performance Testing:

– Drop Test: Simulates potential impacts during handling and transport.

– Vibration Testing: Evaluates the package’s durability under conditions that simulate transportation.

– Thermal Cycling: Determines how packaging withstands extreme temperature variations.

3. Usability Testing:

– Ergonomic Assessments: Ensures that packaging is easy to use, open, and handle.

– Consumer Feedback: Collects real-world feedback on user experience and identifies areas for improvement.

4. Regulatory and Compliance Testing:

– Safety Standards Compliance: Ensures packaging meets local and international regulations.

– Environmental Testing: Evaluates the eco-friendliness and recyclability of the packaging.

5. Visual and Structural Integrity:

– Inspection Techniques: Includes visual checks for defects and automated scanning systems for structural integrity.

6. Microbiological and Chemical Testing:

– Ensures the packaging doesn’t harbor harmful microorganisms or release toxic substances.

To control and maintain quality:

– Statistical Process Control (SPC): Uses statistical methods to monitor and control production processes.

– Total Quality Management (TQM): Proactive approach involving all employees in continuous improvement of processes.

– ISO Certifications: Following standards like ISO 9001 helps in maintaining consistent quality.

– Supplier Quality Management: Regular audits and quality checks on raw material suppliers.

– Automated Quality Control Systems: Incorporates sensors and machine learning to detect defects in real-time.

Implementing these methods ensures that packaging innovations meet high-quality standards and deliver value to consumers.

The Work Process and how to use innovation in packaging

The work process for integrating innovation into packaging involves distinct stages: ideation, research, design, prototyping, testing, and implementation.

1. Ideation: Start with brainstorming sessions to generate creative ideas. Encourage a diverse team to think outside the box and consider sustainability, user experience, and cost-effectiveness.

2. Research: Conduct thorough market research to understand consumer needs, trends, and competitive offerings. Evaluate new materials, technologies, and regulatory requirements.

3. Design: Translate ideas into practical designs. Utilize CAD software to develop detailed models. Focus on functionality, aesthetics, and scalability while ensuring minimal environmental impact.

4. Prototyping: Create prototypes using 3D printing or conventional methods. Assess the feasibility and refine the design based on initial feedback.

5. Testing: Perform rigorous testing to ensure durability, safety, and compliance with industry standards. Collect consumer feedback through focus groups or pilot programs.

6. Implementation: Finalize the design and engage with manufacturing partners for large-scale production. Incorporate quality control measures and streamline logistics for cost efficiency.

### Innovative Strategies in Packaging:

– Smart Packaging: Integrate QR codes, NFC tags, or augmented reality to enhance user engagement and provide additional information.

– Eco-friendly Materials: Adopt biodegradable, recyclable, or compostable materials. Consider innovations like mushroom-based packaging or plantable paper embedded with seeds.

– Minimalistic Design: Reduce material usage by designing packages that are lightweight but robust. Innovations like collapsible containers can save space and reduce transportation emissions.

– Personalization: Use digital printing technology to create customized packaging, enhancing the consumer experience and brand differentiation.

– Functionality: Design packaging that offers added value, such as resealable features, easy-open mechanisms, or multi-purpose uses (e.g., packaging that transforms into a storage container).

By embedding innovation in these stages, businesses can create packaging solutions that are not only functional and cost-effective but also environmentally responsible and appealing to modern consumers.

innovation in packaging Importing questions including Cost,Supplier,Sample,Certification and Market

When considering importing innovative packaging solutions, several key questions must be addressed to ensure a successful venture:

1. Cost:

– What is the per-unit cost of the packaging?

– Are there volume discounts available?

– What are the shipping and import taxes associated with logistics?

– Are there any hidden costs, such as handling fees or custom duties?

2. Supplier:

– Who are the reputable suppliers in the market offering these packaging solutions?

– What is the supplier’s track record in terms of quality, reliability, and delivery timelines?

– Can the supplier provide references or case studies from existing clients?

– What are the terms of payment? Do they offer favorable credit terms?

3. Sample:

– Is it possible to get samples of the innovative packaging before placing a bulk order?

– Are the samples free, or is there a cost associated?

– How long does it take to receive the samples?

– Can the samples be customized to specific needs during the trial phase?

4. Certification:

– Does the packaging comply with international and local safety and quality standards?

– What certifications does the packaging hold, such as ISO, FDA, or CE?

– Are there eco-friendly certifications like FSC (Forest Stewardship Council) or another sustainability standard?

– Can the supplier provide documentation and proof of these certifications?

5. Market:

– What is the demand for innovative packaging in the target market?

– Who are the competitors and what solutions are they offering?

– What is the potential market size and growth rate?

– Are there any regulatory restrictions or preferences for certain types of packaging materials in the target market?

Addressing these questions thoroughly can help ensure that the imported innovative packaging solutions are cost-effective, reliable, compliant, and have a strong market demand.

How to find and select check reliable innovation in packaging manufacturers in China

Finding and selecting reliable innovation in packaging manufacturers in China requires a systematic approach:

1. Research and Identify Potential Manufacturers:

– Online B2B Platforms: Utilize platforms like Alibaba, Global Sources, and Made-in-China to identify manufacturers. Filter by high ratings and read buyer reviews.

– Industry Directories: Check industry-specific directories and trade show listings for reputable companies.

– Trade Associations: Contact packaging industry associations for manufacturer recommendations.

2. Evaluate Credibility:

– Certifications: Verify ISO9001, ISO14001, and other relevant certifications.

– Business License and Compliance: Ensure the manufacturer is legally registered and complies with local regulations.

– Experience: Look for manufacturers with a significant history and a strong track record in innovative packaging.

3. Assess Quality and Innovation:

– Portfolio Review: Request samples and review portfolios for previous innovations.

– R&D Capabilities: Check if they have a dedicated R&D department and inquire about recent product innovations.

– Quality Control: Understand their quality control processes to ensure consistent product quality.

4. Communication and Support:

– Responsiveness: Gauge their communication efficiency and professionalism.

– English Proficiency: Ensure the key contacts are proficient in English for clear communication.

5. Assess Financial Stability:

– Credit Report: Obtain a credit report from a financial institution or through trade references to ensure financial stability.

6. Visit the Facility:

– On-Site Visit: If possible, visit their manufacturing facility to inspect their operation, quality control, and working conditions.

7. Customer References:

– Testimonials: Ask for references from current or past clients and follow up on them.

By following these steps, you can find and select reliable, innovative packaging manufacturers in China.

Background Research for innovation in packaging manufacturers Companies in China, use qcc.com archive.org importyeti.com

China’s packaging manufacturing industry has been undergoing significant innovation driven by increasing demand for sustainable and efficient packaging solutions. Companies are focusing on eco-friendly materials, advanced manufacturing technologies, and smart packaging to meet international standards and consumer preferences.

Key Trends and Companies:

1. Sustainable Materials: Leading manufacturers such as Amcor and Mondi have set up operations in China, emphasizing the use of recycled materials and biodegradable options. Local companies like Changzhou HP Medtech are also innovating with sustainable packaging solutions.

2. Smart Packaging: Chinese firms are integrating IoT and QR code technologies into packaging. Companies like Shenzhen YUTO Packaging are at the forefront, offering smart packaging solutions that provide real-time tracking and anti-counterfeiting features.

3. Advanced Manufacturing: The adoption of automation and AI in the manufacturing process is on the rise. Firms such as Greatview Aseptic Packaging are utilizing robots and AI to optimize production efficiency and quality control.

Resource Utilization:

– qcc.com: This platform highlights economic activities, financial health, and innovation indices of companies. For example, data on companies like Shandong Lipeng shows investment in R&D for sustainable products.

– archive.org: Historical data and publications reveal the evolution of China’s packaging industry. Reports from the early 2000s show the industry’s shift towards eco-friendly practices.

– importyeti.com: Trade data indicates that companies such as Xiamen Yongxin are exporting innovative packaging solutions globally, showing their competitiveness and adherence to international standards.

Overall, China’s packaging manufacturing landscape is vibrant with innovation focusing on sustainability, smart technology, and advanced manufacturing processes. Major global and local players are leveraging these innovations to enhance their market competitiveness and meet evolving consumer demands.

Price Cost Research for innovation in packaging manufacturers Companies in China, use temu.com and 1688.com

Conducting price cost research for innovation in packaging manufacturing companies in China through platforms like Temu.com and 1688.com can provide you a good understanding of market dynamics and costs. Here’s a brief overview based on recent data.

### Temu.com

Temu.com is a comprehensive marketplace with a wide array of packaging options. While the prices can vary widely based on materials, quantities, and customization, here are some general observations:

1. Eco-Friendly Packaging:

– Kraft paper bags with custom printing: Approximately $0.10 – $0.30 per unit for bulk orders (10,000+ units).

– Biodegradable plastic packaging: Around $0.50 – $0.80 per unit.

2. Innovative and Smart Packaging:

– QR Code enabled packaging for product tracking and consumer interaction: Around $0.20 – $0.40 per unit.

– Temperature-sensitive labels: $0.60 – $1.00 per unit.

### 1688.com

1688.com is a wholesale platform that’s part of the Alibaba Group, similar to Alibaba but primarily serving the Chinese market. Prices tend to be lower here due to direct access to manufacturers.

1. Standard Packaging Solutions:

– Custom printed cardboard boxes: $0.05 – $0.15 per unit for high volumes (20,000+ units).

– Plastic packaging, various shapes and sizes: $0.03 – $0.08 per unit.

2. Innovative Materials and Designs:

– Recyclable packaging with lamination: $0.12 – $0.25 per unit.

– Multi-functional packaging (e.g., packaging that doubles as a display stand): $0.30 – $0.50 per unit.

### Considerations

– MOQ (Minimum Order Quantity): Both platforms often have high MOQs which can affect pricing.

– Customization: Detailed customization typically incurs additional costs.

– Shipping and Import Duties: These will add to the overall cost, especially for international buyers.

### Conclusion

If seeking innovative packaging solutions, both Temu.com and 1688.com offer competitive pricing with the advantage of a wide selection and potential for customization. For cost efficiency, high volume orders directly from manufacturers on 1688.com could provide better rates. Keep an eye on shipping costs and other import fees, which are crucial in the final costing for international buyers.

Shipping Cost for innovation in packaging import from China

When importing innovative packaging materials from China, the shipping cost can vary significantly depending on various factors. Understanding these factors will help you manage your budget effectively.

### Key Determinants of Shipping Costs

1. Mode of Shipping:

– Air Freight: Fast but expensive, suitable for lightweight and high-value items.

– Sea Freight: Cost-effective for bulk shipments but slower.

2. Weight and Volume:

– Carriers often charge by volume weight (dimensional weight) or actual weight, whichever is greater.

3. Shipping Route and Distance:

– The origin (port in China) and destination (your country) influence the cost.

4. Type of Packaging:

– Fragile or hazardous materials may incur higher shipping fees due to special handling requirements.

5. Customs and Duties:

– Import duties and taxes vary by country and can add to your overall cost.

6. Additional Services:

– Insurance, tracking, and expedited services can increase costs.

### Example Cost Breakdown

1. Air Freight: Typically ranges from $5 to $10 per kilogram.

2. Sea Freight: Ranges from $1,000 to $3,000 for a 20-foot container.

3. Customs Duties: Vary by product classification but can be a percentage of the shipment’s value.

### Cost-Saving Tips

1. Bulk Shipping: Reduces per-unit cost.

2. Strategic Shipping Schedules: Avoid peak seasons.

3. Trusted Freight Forwarders: Can offer discounts and streamlined customs processes.

### Final Considerations

Planning and negotiating with suppliers and shipping companies can significantly affect your shipping costs. Always get multiple quotes and understand each expense line item. For an exact estimate tailored to your specific shipment needs, consult with a logistics expert or a reputable freight forwarder.

By carefully considering these factors, you can efficiently manage your shipping costs for importing innovative packaging from China.

Compare China and Other innovation in packaging Markets: Products Quality and Price,Visible and Hidden Costs

China and other innovation hubs in packaging markets present distinct profiles in terms of product quality, pricing, and associated costs.

Product Quality and Pricing:

Chinese packaging manufacturers are known for offering relatively low prices due to cheaper labor and material costs. While high-end Chinese manufacturers produce quality comparable to global standards, consistency remains a concern, especially among lower-tier suppliers. In contrast, packaging solutions from Western Europe, North America, and Japan typically exhibit superior quality control, advanced materials, and innovative designs, albeit at higher prices. American and German packaging firms, for example, are leaders in high-tech and sustainable packaging solutions.

Visible and Hidden Costs:

Visible costs include the unit price of packaging products and shipping expenses. Chinese suppliers often offer competitively lower unit prices, which attract volume-driven buyers. However, hidden costs can sway the overall economic benefit. These hidden costs involve quality control, longer lead times, higher defect rates necessitating replacements, and potential compliance issues with international standards. Additionally, the logistical complexity of international shipping from China can incur supplementary costs such as customs duties and handling fees.

In contrast, other innovation hubs, though pricier upfront, may present fewer hidden costs. Their stronger emphasis on R&D leads to innovative solutions, such as biodegradable packaging and smart packaging, which could result in long-term savings through reduced environmental impact or enhanced product shelf-life. Additionally, proximity to Western markets can reduce logistical hurdles.

In summary, while China offers competitive pricing and growing improvements in quality, hidden costs related to quality control and logistics need careful consideration. Other innovation centers, offering advanced, reliable, and sustainable packaging options, may justify their higher prices through reduced hidden costs and superior product quality. The choice hinges on balancing upfront costs with long-term value and specific business needs.

Custom Private Labeling and Branding Opportunities with Chinese innovation in packaging Manufacturers

Custom private labeling and branding represent significant opportunities for businesses, especially when collaborating with China’s innovative packaging manufacturers. These manufacturers are renowned for their advanced technology, cost-efficiency, and rapid production capabilities, making them ideal partners for launching distinctive packaging solutions.

1. Innovative Designs: Chinese manufacturers frequently invest in R&D, resulting in cutting-edge packaging designs that stand out. They offer customizable options in materials, shapes, colors, and finishes, enabling businesses to craft unique branding experiences that catch consumer attention.

2. Sustainability Focus: With the global pivot towards eco-friendly solutions, many Chinese manufacturers provide sustainable packaging options. Using biodegradable materials, recycled content, and minimalistic designs, they help brands align with environmentally conscious market trends and regulatory requirements.

3. Cost Efficiency: Competitive pricing is a hallmark of Chinese manufacturing, allowing businesses to achieve high-quality packaging without breaking the bank. This cost efficiency extends to both small and large production runs, making it accessible for startups and established companies alike.

4. Rapid Turnaround: The agility of Chinese production facilities ensures quick turnarounds, critical for businesses aiming to respond swiftly to market demands and seasonal trends. Advanced logistics networks further support timely global distribution.

5. Advanced Printing and Finishing: High-quality printing techniques such as UV printing, embossing, and foil stamping offered by Chinese manufacturers enable intricate and premium branding. These enhancements elevate product perception and reinforce brand identity.

6. Integrated Services: Many Chinese manufacturers provide end-to-end services, from initial design consultation and prototyping to full-scale production and packaging. This holistic approach simplifies the supply chain, reducing coordination efforts and ensuring consistency.

Engaging with Chinese packaging innovators provides a gateway to exceptional custom private labeling and branding opportunities. By leveraging their technological prowess, sustainability practices, and cost benefits, businesses can enhance their product appeal and market presence effectively.

Tips for Procurement and Considerations when Purchasing innovation in packaging

When procuring innovative packaging solutions, there are several key considerations to ensure the best outcomes for both product protection and market appeal.

1. Sustainability: Opt for materials that are eco-friendly, recyclable, or compostable. Consumers are increasingly driven by environmental concerns, and sustainable packaging can improve brand image and customer loyalty.

2. Functionality: The packaging must effectively protect the product from damage, contamination, and spoilage. Ensure it provides a seal that maintains product integrity throughout its shelf life and transportation.

3. Cost-Efficiency: While innovation often comes at a premium, evaluate the cost-benefit ratio. Consider long-term savings from reduced waste, improved logistics, and potential for increased sales due to better customer experience.

4. Consumer Convenience: Easy-to-open, resealable, and ergonomic designs enhance user experience. Packaging that offers convenience can differentiate your product in a crowded market.

5. Regulatory Compliance: Ensure the packaging materials and design meet all relevant regulations and standards in the regions where your product will be sold. This includes food safety regulations, labeling requirements, and material restrictions.

6. Brand Alignment: The packaging should reflect your brand’s ethos and messaging. Innovative design can help convey your brand’s commitment to quality and cutting-edge solutions.

7. Technology Integration: Consider smart packaging solutions that incorporate technology like QR codes, NFC tags, or AR features. These can enhance consumer engagement, provide additional information, and support traceability.

8. Supplier Reliability: Select vendors with a proven track record of quality and innovation. Reliable suppliers can offer consistency, flexibility, and support for scaling up production as needed.

In summary, balancing functionality, sustainability, cost, and consumer appeal while aligning with regulatory standards and brand ethos are crucial when purchasing innovative packaging solutions.

FAQs on Sourcing and Manufacturing innovation in packaging in China

Certainly! Here are some Frequently Asked Questions (FAQs) on Sourcing and Manufacturing Innovation in Packaging in China:

1. Why should I consider sourcing packaging from China?

China offers competitive pricing, a wide range of materials, advanced manufacturing technologies, and a vast supplier network. Coupled with increasing innovation in packaging, sourcing from China can lead to cost-efficiency and high-quality products.

2. What types of innovative packaging solutions are available in China?

China is increasingly adopting sustainable packaging materials like biodegradable plastics, recyclable paper, and reusable containers. Smart packaging solutions, such as QR code-enabled tracking and interactive elements, are also widely available.

3. How do I find reliable suppliers in China for packaging?

Start with thorough research using B2B platforms like Alibaba, Global Sources, and Made-in-China. Make sure to request samples, check company certifications (ISO, FSC, etc.), and consider third-party audits or inspections.

4. What are the key considerations for quality control?

Establish clear specifications and standards, conduct regular inspections, and consider working with third-party quality assurance companies. Keeping close communication with your supplier helps ensure alignment on quality expectations.

5. Are Chinese packaging manufacturers adhering to global sustainability standards?

Many manufacturers are increasingly compliant with international sustainability standards, such as ISO 14001 for environmental management. It is essential to verify certifications and request documentation.

6. What is the typical lead time for packaging orders?

Lead times vary but generally range from 2 to 6 weeks, depending on the complexity of the order and the manufacturer’s capacity. Always plan for additional time for shipping and customs clearance.

7. How does the innovation in Chinese packaging benefit my business?

Innovative packaging solutions from China can improve product aesthetic, enhance consumer engagement, and reduce environmental impact, thereby boosting your brand’s marketability and sustainability credentials.

By understanding these key aspects, businesses can effectively leverage China’s extensive resources and innovation in packaging to their advantage.