List Technical Parameters of “form fill seal packaging machine”

Form fill seal packaging machines come with various technical parameters that determine their performance and capabilities. Some of these parameters include:

1. Speed: The speed at which the machine can package products, usually measured in units per minute.

2. Machine size: The overall dimensions of the machine, including length, width, and height.

3. Packaging material compatibility: The types of materials that can be used with the machine, such as film, foil, or paper.

4. Bag size range: The range of bag sizes that the machine can accommodate, from small packets to larger containers.

5. Filling range: The range of product weights or volumes that the machine can handle during the packaging process.

6. Sealing type: The type of sealing mechanism used by the machine, such as heat sealing, ultrasonic sealing, or zipper sealing.

7. Power supply: The electrical requirements of the machine, including voltage and frequency.

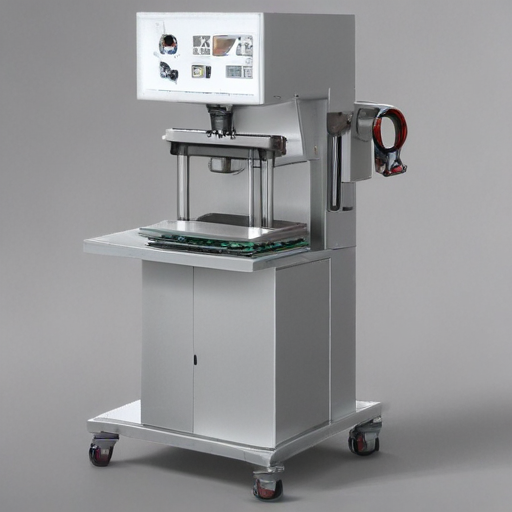

8. Control system: The type of control system used to operate the machine, such as PLC or touchscreen.

9. Safety features: The various safety mechanisms incorporated into the machine to prevent accidents or damage.

10. Maintenance requirements: The recommended maintenance schedule and procedures for keeping the machine in good working condition.

These technical parameters play a crucial role in determining the overall performance and efficiency of a form fill seal packaging machine, making it essential for manufacturers to consider them when selecting the right machine for their packaging needs.

List Product features of “form fill seal packaging machine”

Some product features of a form fill seal packaging machine include:

1. Versatility: These machines are able to package a wide range of products including liquids, powders, granules, and solid items. This makes them suitable for various industries such as food and beverage, pharmaceutical, and cosmetics.

2. Efficiency: Form fill seal machines are known for their high-speed packaging capabilities, allowing for quick and efficient production. This can help companies increase their output and meet customer demands.

3. Customization: These machines offer the flexibility to customize packaging options such as pouch size, shape, and material, ensuring that the final product meets the specific requirements of the customer.

4. Easy to use: Form fill seal machines are user-friendly and can be easily operated with minimal training. This helps to reduce downtime and improve overall productivity in the production process.

5. Cost-effective: Investing in a form fill seal packaging machine can help companies save money in the long run. These machines are durable and require minimal maintenance, reducing operating costs over time.

6. Hygienic: Many form fill seal machines are designed with sanitary features that help maintain product integrity and extend shelf life. This is particularly important in industries such as food and pharmaceuticals where hygiene is crucial.

7. Compact design: Form fill seal machines are typically compact in size, making them suitable for companies with limited floor space. This allows for easy integration into existing production lines.

Overall, form fill seal packaging machines offer a range of benefits for companies looking to improve their packaging processes, increase efficiency, and reduce costs.

List Application of “form fill seal packaging machine”

1. Food Industry: Form fill seal packaging machines are commonly used in the food industry to package a wide range of products such as snacks, candies, frozen foods, grains, and spices. These machines ensure that the products are securely sealed in pouches or bags to maintain their freshness and extend their shelf life.

2. Pharmaceutical Industry: In the pharmaceutical industry, form fill seal packaging machines are used to package medications, supplements, and other healthcare products. These machines provide efficient and reliable packaging solutions that comply with strict regulations and ensure the safety and integrity of the products.

3. Cosmetics Industry: Form fill seal packaging machines are also utilized in the cosmetics industry to package various beauty and personal care products such as lotions, creams, serums, and masks. These machines enable manufacturers to efficiently package their products in airtight pouches or sachets to preserve their quality and extend their shelf life.

4. Household Products Industry: Form fill seal packaging machines are widely used in the household products industry to package cleaning agents, detergents, and other household consumables. These machines help manufacturers package their products quickly and efficiently while ensuring that they are securely sealed to prevent leaks or spills.

5. Pet Food Industry: Form fill seal packaging machines are essential in the pet food industry for packaging dry kibble, treats, and supplements for pets. These machines enable manufacturers to package pet food products in pouches or bags that are sealed to maintain freshness and prevent contamination.

Overall, form fill seal packaging machines are versatile and widely used across various industries to efficiently package a wide range of products while ensuring product quality, safety, and shelf life.

List Various Types of “form fill seal packaging machine”

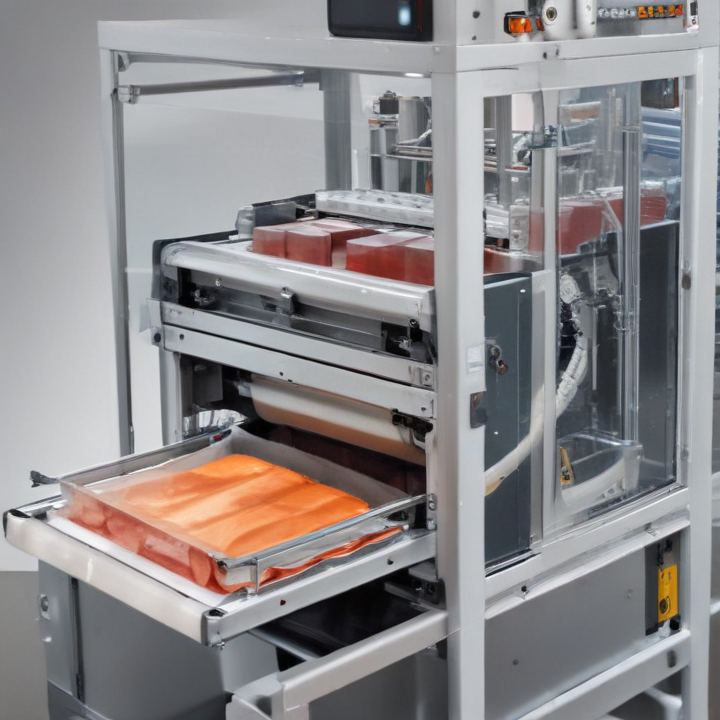

1. Vertical Form Fill Seal (VFFS) Machine: This type of packaging machine is commonly used for packing various types of products like snacks, grains, powder, and liquid in the form of bags. The machine forms the bag from a roll of film, fills it with the product, and seals it, all in a vertical motion.

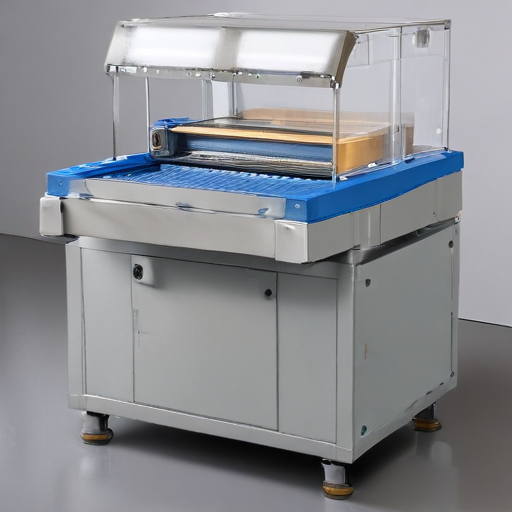

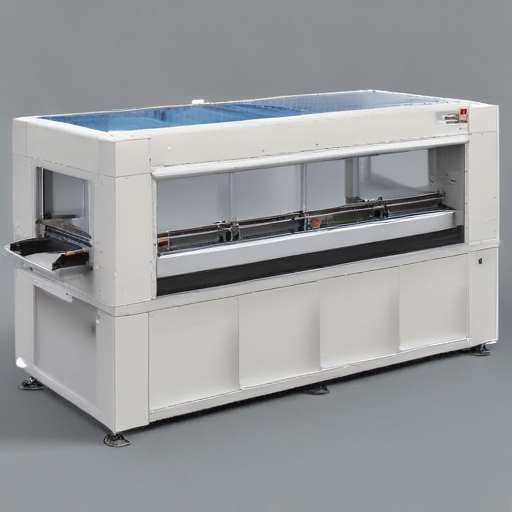

2. Horizontal Form Fill Seal (HFFS) Machine: HFFS machines are used for packing products like bars, cookies, and other solid items in pouches or sachets. The machine forms the pouch horizontally, fills it with the product, and seals it in a continuous process.

3. Pre-Made Pouch Fill Seal Machine: This type of machine is used for filling pre-made pouches with products like snacks, coffee, and pet food. The machine only fills and seals the pouch, eliminating the need for forming the pouch from a roll of film.

4. Thermoform Fill Seal (TFFS) Machine: TFFS machines are used for packing products like meat, cheese, and pharmaceuticals in trays or containers. The machine forms the tray from a roll of film, fills it with the product, and seals it using heat.

5. Stick Pack Fill Seal Machine: Stick pack machines are used for packing products like sugar, salt, and instant coffee in stick-shaped pouches. The machine forms the stick pouch, fills it with the product, and seals it in a narrow and elongated form.

6. Sachet Fill Seal Machine: Sachet machines are used for packing single-dose products like sugar, sauce, and shampoo in small pouches. The machine forms the sachet, fills it with the product, and seals it for individual use.

Each type of form fill seal packaging machine offers specific advantages and is designed to meet the packaging needs of different industries and products.

Custom Manufacturing Options for form fill seal packaging machine

When looking for custom manufacturing options for a form fill seal packaging machine, there are several key factors to consider. These machines are used to automatically fill and seal bags or pouches with various products, such as food items, pharmaceuticals, or household goods.

One option to consider is the size and capacity of the machine. Depending on the volume and type of products to be packaged, you may need a machine with specific dimensions and capabilities. Customizing the size of the machine can ensure it fits seamlessly into your production line and meets your packaging needs.

Another important consideration is the type of material the machine is designed to work with. Some form fill seal machines are designed for specific types of packaging materials, such as plastic films, foil, or paper. Customizing the machine to accommodate the specific material you plan to use can ensure optimal performance and quality of the finished product.

You may also want to explore custom features and functions to enhance the efficiency and versatility of the machine. This could include options for adjusting fill weights, adding printing or labeling capabilities, integrating with other packaging equipment, or incorporating automation technology for increased speed and accuracy.

Overall, custom manufacturing options for form fill seal packaging machines can be tailored to your specific requirements and preferences. By working with a reputable manufacturer or supplier, you can ensure your machine is optimized for your unique production needs and helps you achieve your packaging goals.

List Quality Control and The Manufacturing Process of “form fill seal packaging machine”

Quality control for a form fill seal packaging machine involves several key steps to ensure its efficient operation and production of high-quality packaging. The manufacturing process includes the following quality control measures:

1. Material inspection: Quality control starts with the inspection of raw materials used in the manufacturing of the machine. This ensures that only high-quality materials are used, which are crucial for the durability and performance of the machine.

2. Component testing: Each component of the packaging machine is tested for functionality, durability, and compatibility with other components. This helps in identifying any defects or issues that may affect the overall performance of the machine.

3. Assembly inspection: Once all components are tested and approved, they are assembled to form the complete machine. The assembled machine is then inspected to ensure that all parts are properly aligned and functioning correctly.

4. Operational testing: After assembly, the machine undergoes extensive testing to ensure that it meets the required operational standards. This includes testing its speed, accuracy, and functionality in producing and sealing packaging.

5. Final inspection: Before the machine is shipped to the customer, a final inspection is carried out to ensure that it meets all quality control standards. Any defects or issues are addressed and resolved before the machine is delivered.

Overall, quality control is an essential part of the manufacturing process of a form fill seal packaging machine to ensure that it meets the highest standards of quality and performance. By following these quality control measures, manufacturers can ensure that their machines operate efficiently and produce high-quality packaging for their customers.

How to use “form fill seal packaging machine”

Form fill seal packaging machines are used to automatically form, fill, and seal bags or pouches with various products such as snacks, liquids, powders, and frozen foods. Here’s how to use a form fill seal packaging machine:

1. Preparation: Before using the machine, make sure it is properly set up and calibrated for the specific product and packaging material being used. This includes adjusting the machine settings for bag length, width, and sealing temperature.

2. Loading: Place the roll of packaging film onto the machine’s film unwind shaft and thread it through the machine’s rollers and sealing jaws. Make sure the film is aligned correctly and secure the film in place.

3. Forming: The machine will then automatically form the packaging material into a bag or pouch by creating the desired shape and size based on the machine settings.

4. Filling: Once the bag is formed, fill it with the desired product using a product feeder or vibratory feeder. The machine will ensure accurate and consistent filling of each bag.

5. Sealing: The machine will then seal the filled bag using heat sealing or ultrasonic sealing technology, depending on the machine configuration. The bags are sealed to prevent contamination and ensure product freshness.

6. Cutting and finishing: After sealing, the machine will cut the bags apart and deliver them to the output conveyor for further processing or packaging.

7. Monitoring: Throughout the packaging process, monitor the machine’s performance, product flow, and bag quality to ensure everything is running smoothly.

By following these steps, you can effectively use a form fill seal packaging machine to efficiently package various products for retail or distribution.

List Properties and Terms of “form fill seal packaging machine”

Form fill seal packaging machines are versatile systems used in the packaging industry to automate the filling, sealing, and packaging of various types of products. Some key properties and terms associated with form fill seal packaging machines include:

1. Forming: The process of creating packaging containers or bags from a roll of film or pre-made pouches.

2. Filling: The automated process of filling the formed packaging containers with the desired product, whether it be liquid, solid, or powdered.

3. Sealing: The process of sealing the filled packaging containers to protect the product inside and ensure product freshness.

4. Packaging speed: The speed at which the machine can form, fill, and seal the packaging containers, typically measured in units per minute or hour.

5. Film roll: The roll of packaging material, such as plastic film, that is used to create the packaging containers.

6. Hopper: The container where the product is stored before being fed into the packaging machine for filling.

7. PLC control: Programmable Logic Controller that governs the operations of the machine, including filling, sealing, and packaging.

8. Changeover time: The time it takes to switch the machine from one product or packaging format to another.

9. OEE (Overall Equipment Efficiency): A metric used to measure the effectiveness and productivity of the packaging machine.

10. Auger filler: A type of filling mechanism that uses an auger to accurately dispense powdered or granular products into the packaging containers.

Overall, form fill seal packaging machines are valuable assets in the packaging industry, offering efficiency, speed, and versatility in packaging a wide range of products for various industries.

List The Evolution history of “form fill seal packaging machine”

The form fill seal packaging machine has evolved significantly over the years, continually improving in efficiency, speed, and versatility.

The early versions of the form fill seal machines were quite basic, using manual labor to fill products into pre-formed bags which were then sealed. As technology advanced, so did the machines, with the introduction of automatic weighing, filling, and sealing processes.

In the 1960s and 70s, vertical form fill seal machines became popular, allowing for faster and more efficient packaging of products such as snacks and candies. These machines were able to form the bags, fill them with product, and then seal them in one continuous process.

By the 1980s, horizontal form fill seal machines were introduced, offering even more flexibility and speed in packaging. These machines could handle a wider range of product sizes and shapes, making them ideal for a variety of industries including food, pharmaceuticals, and household products.

In recent years, advancements in technology have led to the development of high-speed form fill seal machines that can package products at rates of up to 200 bags per minute. These machines are capable of handling a wide range of packaging materials including flexible films, paper, and foil.

Overall, the evolution of form fill seal packaging machines has been marked by continuous innovation and improvement, resulting in machines that are faster, more efficient, and more versatile than ever before.

How to Select a Reliable form fill seal packaging machine

When selecting a reliable form fill seal (FFS) packaging machine, there are several key factors to consider to ensure you choose the right machine for your specific packaging needs.

First, determine the type of product you will be packaging and the packaging requirements, such as size, weight, and type of material. This will help you narrow down the options and find a machine that can handle your specific product.

Next, consider the speed and efficiency of the machine. Look for a machine that can meet your production requirements and can keep up with the demand without sacrificing quality. Additionally, consider the ease of use and maintenance of the machine to ensure smooth operation and minimize downtime.

It is also important to consider the reputation and reliability of the manufacturer. Look for a reputable company with a proven track record of producing high-quality packaging machines that are reliable and durable. Reading reviews and testimonials from other customers can also help you gauge the reliability of the machine.

Lastly, consider your budget and compare prices from different manufacturers to find a machine that fits within your budget while still meeting your packaging requirements. Keep in mind that investing in a higher quality machine may cost more upfront but can save you money in the long run by reducing maintenance and repair costs.

Overall, selecting a reliable FFS packaging machine involves careful consideration of your specific packaging needs, the machine’s speed and efficiency, the manufacturer’s reputation, and your budget. By taking the time to research and compare different options, you can ensure you choose a reliable machine that will meet your packaging needs for years to come.

List “form fill seal packaging machine” FAQ

1. What is a form fill seal packaging machine?

A form fill seal packaging machine is a type of packaging equipment that forms the packaging, fills it with a product, and then seals it all in one continuous process. It is commonly used in the food, pharmaceutical, and personal care industries.

2. How does a form fill seal packaging machine work?

The machine starts by forming a packaging material into a specific shape, then it fills the formed pouch with the product, and finally seals the pouch to ensure it is secure and airtight. This process is automated and can be adjusted based on the specific requirements of the product being packaged.

3. What are the benefits of using a form fill seal packaging machine?

Some of the key benefits of using a form fill seal packaging machine include increased production speed, reduced labor costs, improved product consistency, and enhanced packaging efficiency. Additionally, the machines are versatile and can be easily customized to accommodate different shapes and sizes of packaging.

4. Are form fill seal packaging machines suitable for all types of products?

Form fill seal packaging machines are versatile and can be used for a wide range of products including dry goods, liquids, powders, granules, and even products with irregular shapes. However, it is important to consult with a packaging expert to determine the best machine and packaging material for your specific product.

5. How can I maintain and troubleshoot a form fill seal packaging machine?

Regular maintenance, cleaning, and calibration of the machine are essential to ensure optimal performance. Additionally, having a trained operator who can troubleshoot common issues such as sealing problems, fill accuracy, and machine malfunctions is crucial to maintain productivity and efficiency.

Top 10 FAQ with answer about form fill seal packaging machine for Buyer Sourcing from China

1. What is a form fill seal packaging machine?

A form fill seal packaging machine is a type of automated packaging equipment used to form a package, fill it with a product, and seal it all in one continuous process.

2. What are the advantages of using a form fill seal packaging machine?

Some advantages of using a form fill seal packaging machine include increased efficiency, reduced labor costs, improved packaging consistency, and decreased risk of contamination.

3. How do I choose the right form fill seal packaging machine for my product?

When choosing a form fill seal packaging machine, consider factors such as the type of product being packaged, desired packaging style, production speed, and budget.

4. What types of products can be packaged using a form fill seal packaging machine?

Form fill seal packaging machines are versatile and can package a wide range of products, including powders, granules, liquids, and solids.

5. What is the production capacity of a form fill seal packaging machine?

Production capacity varies depending on the machine’s specifications, but most form fill seal packaging machines can package hundreds to thousands of units per hour.

6. How reliable are form fill seal packaging machines from China?

Chinese form fill seal packaging machines are known for their reliability, efficiency, and affordability. However, it is important to research and verify the reputation of the manufacturer before making a purchase.

7. Can a form fill seal packaging machine be customized to fit specific packaging requirements?

Yes, many manufacturers offer customization options to tailor the machine to meet specific packaging requirements, such as bag size, shape, and material.

8. How long does it take to install and set up a form fill seal packaging machine?

Installation and setup time can vary depending on the complexity of the machine and the manufacturer’s instructions. Typically, it may take a few hours to a few days to fully install and set up the machine.

9. What kind of maintenance is required for a form fill seal packaging machine?

Regular maintenance, such as cleaning, lubricating, and inspecting components, is essential to ensure the machine’s optimal performance and longevity.

10. Is training provided for operating a form fill seal packaging machine?

Many manufacturers offer training programs or guides to help operators learn how to properly operate and maintain the form fill seal packaging machine.