Top 10 form fill seal packaging machine in China introduce,list main products and website if have

Sure, here are 10 top form-fill-seal (FFS) packaging machine manufacturers in China, including a brief introduction, main products, and websites if available:

1. **JOIEPACK Industrial Co., Ltd.**

– **Main Products:** Horizontal form-fill-seal machines, automatic and semi-automatic packing systems.

– **Website:** [joiepack.com](http://www.joiepack.com/)

2. **Ruian Honetop Machinery Co., Ltd.**

– **Main Products:** Vertical form-fill-seal machines, multi-head weighers, flow pack machines.

– **Website:** [honetop.com](http://www.honetop.com/)

3. **Wenzhou Echo Machinery Co., Ltd.**

– **Main Products:** Rotary and vertical form-fill-seal machines, packaging lines for snacks, powders, liquids.

– **Website:** [echomachinery.com](http://www.echomachinery.com/)

4. **Shanghai Acepack Intelligent Technology Co., Ltd.**

– **Main Products:** Vertical and horizontal form-fill-seal machines, stand-up pouch packing machines.

– **Website:** [acepackgroup.com](http://www.acepackgroup.com/)

5. **Foshan Coretamp Packaging Machinery Co., Ltd.**

– **Main Products:** Vertical form-fill-seal machines, pillow packing machines, granule/powder/liquid packing machines.

– **Website:** [coretamp.com](http://www.coretamp.com/)

6. **Zhejiang Dingye Machinery Co., Ltd.**

– **Main Products:** Vertical and horizontal form-fill-seal machines, vacuum packaging machines.

– **Website:** [ding-ye.com](http://www.ding-ye.com/)

7. **Ruian Trustar Pharma & Packing Equipment Co., Ltd.**

– **Main Products:** Vertical form-fill-seal machines, sachet packing machines, capsule filling machines.

– **Website:** [trustarmachinery.com](http://www.trustarmachinery.com/)

8. **Hunan Grand Packing Machinery Co., Ltd.**

– **Main Products:** Horizontal form-fill-seal machines, pharmaceutical packing machines, blister packing machines.

– **Website:** [grand-packing.com](http://www.grand-packing.com/)

9. **Xiamen Sengong Packing Equipment Co., Ltd.**

– **Main Products:** Vertical form-fill-seal machines, vacuum packing machines, granule/powder packing machines.

Types of form fill seal packaging machine

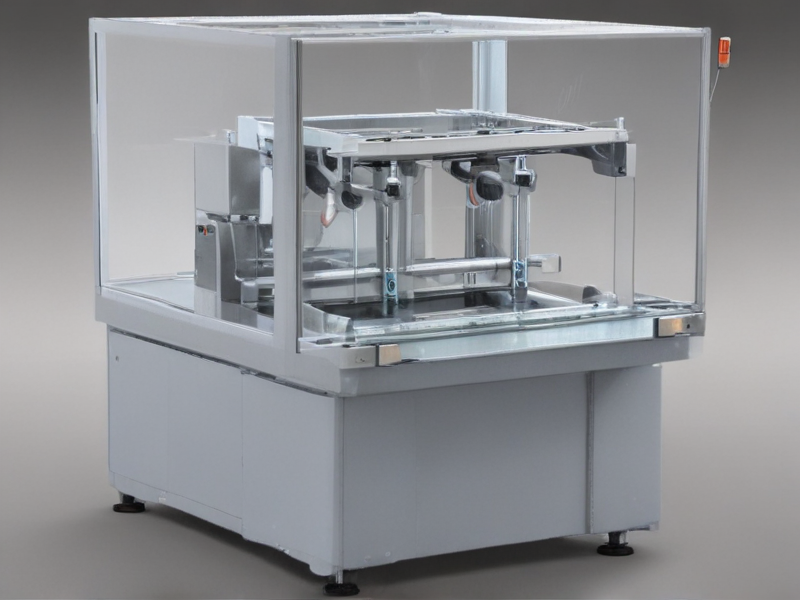

Form fill seal (FFS) packaging machines are classified based on their orientation and application. Here are the primary types:

1. **Vertical Form Fill Seal (VFFS) Machines**: These machines form, fill, and seal packages in a vertical orientation. They are ideal for packaging granules, powders, liquids, and semi-liquids. VFFS machines are widely used for snacks, coffee, spices, and sauces. Key advantages include high-speed operation and compact footprint.

2. **Horizontal Form Fill Seal (HFFS) Machines**: In HFFS machines, packaging starts horizontally. Ideal for packaging larger items or items that need to lie flat, such as biscuits, candies, and medical devices. These machines are particularly suitable for products that require precise placement or bundling.

3. **Thermoforming FFS Machines**: These machines use heat to mold packaging material into specific shapes before filling and sealing. Commonly used for dairy products, meat, and pharmaceutical items, thermoforming machines offer robust and tamper-evident packaging solutions.

4. **Blister Packaging Machines**: A subset of thermoforming FFS machines, blister packaging is used mainly for pharmaceuticals, consumer goods, and small electronics. Blisters provide a clear, protective cover for individual items, enhancing product visibility and security.

5. **Sachet Packaging Machines**: These machines produce small, single-use packets (sachets) for various products like shampoo, sauces, and powders. Sachet packaging offers convenience in dosage, portability, and extended shelf life.

Each type of FFS machine serves specific packaging needs, enhancing product preservation, safety, and consumer convenience. Selecting the right machine depends on factors such as product type, production volume, and packaging material.

Pros and Cons of Using form fill seal packaging machine

**Form Fill Seal (FFS) Packaging Machine: Pros and Cons**

**Pros:**

1. **Efficiency:**

– **Speed:** FFS machines can operate at high speeds, significantly increasing production rates.

– **Automation:** Reduces manual labor, minimizes human error, and ensures consistent quality.

2. **Cost-Effective:**

– **Material Efficiency:** Utilizes materials efficiently, often resulting in lower packaging costs.

– **Reduced Labor Costs:** Less manual operation decreases overall labor expenses.

3. **Versatility:**

– **Product Variety:** Suitable for a wide range of products including liquids, powders, and solids.

– **Packaging Styles:** Accommodates various packaging formats like sachets, pouches, and bags.

4. **Hygiene and Safety:**

– **Sealed Environment:** Reduces contamination risks by packaging products in a controlled environment.

– **Compliance:** Often conforms to strict hygiene standards, crucial for food and pharmaceutical industries.

5. **Customization:**

– **Branding:** Allows for customizable packaging designs, enhancing brand visibility.

– **Flexibility:** Adjustable to different sizes and packaging requirements.

**Cons:**

1. **Initial Investment:**

– **High Cost:** FFS machines can be expensive to purchase and install, which might be a barrier for small businesses.

2. **Maintenance:**

– **Technical Expertise:** Requires skilled personnel for maintenance and troubleshooting.

– **Downtime:** Maintenance and repairs can lead to production downtime, affecting efficiency.

3. **Complexity:**

– **Setup:** Initial setup and configuration can be complex and time-consuming.

– **Training:** Operators require training to handle machine operations effectively.

4. **Material Limitations:**

– **Compatibility:** Not all packaging materials are compatible with FFS machines, limiting material choices.

5. **Energy Consumption:**

– **High Energy Use:** These machines can consume considerable amounts of energy, impacting operational costs and environmental footprint.

In summary, FFS packaging machines offer significant efficiency, versatility, and hygiene benefits, but they come with high initial costs, maintenance requirements, and energy consumption considerations. Businesses must weigh these factors to determine if FFS technology aligns with their operational goals.

form fill seal packaging machine Reference Specifications (varies for different product)

A Form Fill Seal (FFS) packaging machine is a versatile piece of equipment used in various industries for packaging products efficiently. The specifications of an FFS machine may vary according to the type of products being packaged—such as powders, granules, liquids, or solids. Here are some key reference specifications commonly considered:

### Machine Type

1. **Horizontal Form Fill Seal (HFFS):** Suitable for solid products, snacks, biscuits.

2. **Vertical Form Fill Seal (VFFS):** Ideal for powders, grains, liquids.

### Speed & Capacity

– **Production Speed:** Ranges from 30 to 150 packs per minute.

– **Packaging Volume:** Adjustable, typically from 5g to 5000g depending on product and pouch size.

### Material Compatibility

– **Film Type:** Suitable for laminated films, PE, PP, and other heat-sealable materials.

### Pouch Formats

– Capable of forming various pouch types such as pillow, gusseted, stand-up pouches, three- or four-side seal, and more.

### Dimensions

– **Machine Dimensions:** Depend on model but generally vary from compact models for small businesses to larger units for high production rates.

– **Pouch Dimensions:** Customizable, generally ranging from 50mm x 50mm to 300mm x 400mm.

### Filling Mechanism

– **Volumetric:** For granules and free-flowing products.

– **Auger:** For powdered products.

– **Pump/Flow Meter:** For liquids.

### Control Systems

– **PLC (Programmable Logic Controller):** For user-friendly operations and automation.

– **HMI (Human Machine Interface):** Touchscreen interface for easy control and monitoring.

### Power & Air Requirements

– **Electrical:** Typically 220V/380V, 50/60Hz.

– **Air Supply:** 6-8 bar for pneumatic operations.

### Additional Features

– **Weighing System:** Integrated load cells for accurate product dosing.

– **Printer Integration:** For date codes and batch numbers.

– **Sensors:** For film detection, product presence, and other safety measures.

### Construction Material

– **Stainless Steel:** For parts in contact with products, ensuring hygiene and compliance with food safety standards.

These specifications ensure the FFS packaging machine can meet diverse packaging needs across various industries, offering efficiency, flexibility, and reliability.

Applications of form fill seal packaging machine

Form Fill Seal (FFS) packaging machines are versatile and widely used in various industries due to their efficiency, cost-effectiveness, and ability to maintain product integrity. Here are some key applications:

1. **Food and Beverage Industry**:

– **Snack Foods**: Chips, nuts, and popcorn are commonly packaged using FFS machines to ensure freshness and extended shelf life.

– **Dairy**: Yogurt, cheese, and milk are often packed in pouches or sachets.

– **Liquids**: Juices, sauces, and soups use FFS technology for precise volume control and convenient packaging formats.

2. **Pharmaceuticals**:

– **Tablets and Capsules**: Blister packs and sachets protect against contamination and are easy to dispense.

– **Liquids**: Syrups and topical medications benefit from aseptic packaging options to maintain sterility.

3. **Personal Care and Cosmetics**:

– **Creams and Lotions**: Convenient tube or sachet packaging makes application easy.

– **Shampoos and Conditioners**: Single-use sachets are popular for travel and samples.

4. **Cleaning and Household Products**:

– **Detergents**: Powders, tablets, and liquids are efficiently packed in various sizes.

– **Cleaners**: Small sachets for single-use convenience or larger packets for daily use.

5. **Agricultural Products**:

– **Seeds and Fertilizers**: Secure packaging ensures product integrity during distribution.

– **Pesticides**: Safe and precise packaging minimizes user exposure and environmental impact.

6. **Medical Devices**:

– **Single-use Devices**: Sterile pouches for items like syringes and bandages ensure hygiene and safety.

7. **Industrial Goods**:

– **Hardware**: Small parts like screws and nails can be efficiently sorted and packaged.

– **Chemicals**: Protects volatile or moisture-sensitive products.

FFS technology’s adaptability to different materials, including plastic films, laminates, and aluminum, alongside its ability to handle various product forms (liquid, powder, granules, and solids), makes it indispensable in modern manufacturing and packaging.

Material of form fill seal packaging machine

A Form Fill Seal (FFS) packaging machine is a type of automated assembly-line product packaging system commonly used for food, pharmaceuticals, and a variety of other consumer goods. The materials used in constructing these machines are essential for ensuring durability, reliability, and hygienic operations. Key materials include:

1. **Stainless Steel**:

– **Grades**: Typically 304 or 316 stainless steel.

– **Usage**: This is the most common material used in FFS machines. It offers excellent corrosion resistance, especially critical in wet environments or for packaging sensitive products such as food and pharmaceuticals. Stainless steel also has a smooth surface that’s easy to clean and sterilize, making it suitable for maintaining hygiene standards.

2. **Aluminum**:

– **Usage**: Certain parts of the machine, like the framework or lightweight components, may be constructed from aluminum. It provides a good balance of strength and light weight and is also resistant to corrosion.

3. **Plastics**:

– **Types**: Engineering plastics such as Polyethylene (PE), Polyethylene Terephthalate (PET), and Polyvinyl Chloride (PVC).

– **Usage**: These are used for parts that require flexibility, impact resistance, and low friction. Plastics are often used for components like the film feeding mechanisms and sealing jaws.

4. **Titanium**:

– **Usage**: Used in high-wear parts, titanium offers superior strength, corrosion resistance, and longevity, although it is more costly.

5. **Rubber and Elastomers**:

– **Types**: Food-grade silicone and other specialized rubbers.

– **Usage**: Employed in seals, gaskets, and other components requiring elasticity and chemical resistance.

6. **Special Coatings**:

– **Types**: Teflon or other non-stick coatings.

– **Usage**: Applied to surfaces that come into contact with adhesive products to prevent sticking and facilitate easy cleaning.

In summary, the materials used in FFS machines are chosen based on their strength, corrosion resistance, hygiene, and suitability for contact with various products. Stainless steel remains the preferred choice due to its robust properties and compliance with health standards.

Quality Testing Methods for form fill seal packaging machine and how to control the quality

Quality testing for form fill seal (FFS) packaging machines is crucial to ensure product safety, compliance, and customer satisfaction. Key methods and controls include:

1. **Leak Testing**: Conduct vacuum testing or dye penetration to detect seal integrity issues. Leak detectors can be integrated with the machine for continuous monitoring.

2. **Seal Strength Testing**: Utilize tensile testers to measure the force required to break the seal, ensuring consistent strength across all packages.

3. **Visual Inspections**: Regularly inspect packages for defects such as wrinkles, misalignments, or contaminants. Automated vision systems can enhance precision.

4. **Material Quality Tests**: Check packaging material characteristics like thickness, barrier properties, and compatibility with the product to maintain package integrity.

5. **Environmental Control**: Maintain proper storage conditions (temperature, humidity) for packaging materials to prevent degradation.

6. **Performance Validation**: Conduct regular performance tests to ensure the machine operates within specified parameters, including filling accuracy and sealing temperature.

7. **Calibration and Maintenance**: Routine calibration of sensors and actuators, along with scheduled preventive maintenance, helps in maintaining optimal machine performance.

8. **Statistical Process Control (SPC)**: Implement SPC to monitor and control the production process. Collect data on critical parameters and use control charts to identify and address variations.

9. **Traceability Systems**: Integrate traceability systems to track batches and identify any issues promptly, ensuring quick corrective actions.

10. **Operator Training**: Ensure that operators are well-trained in machine operation, troubleshooting, and quality control procedures.

By combining these methods, manufacturers can effectively control and improve the quality of FFS packaging, leading to higher reliability and customer satisfaction.

The Work Process and how to use form fill seal packaging machine

A Form Fill Seal (FFS) packaging machine automates the packaging process by forming, filling, and sealing bags or pouches from a continuous roll of packaging film. Here’s a concise outline of its work process and usage:

### Work Process:

1. **Film Unwinding**: A roll of flat packaging film is loaded onto the machine. The film gradually unwinds and feeds into the machine.

2. **Forming**: The machine folds the film into the desired shape, typically a tube. This is often achieved through forming collars or molds.

3. **Sealing the Sides**: The machine seals the film along its edges to create a continuous tube. This step ensures that the package will be secure and leak-proof.

4. **Filling**: The product (liquid, granules, or powders) is dispensed into the formed tube. The filling unit works in synchronization with the package forming process to ensure accurate and efficient filling.

5. **Top and Bottom Sealing**: After filling, the top of one package and the bottom of the next are sealed simultaneously. This process may involve heat sealing, ultrasonic sealing, or adhesive application.

6. **Cutting**: The filled and sealed package is cut from the continuous film, creating individual, ready-for-sale products.

### How to Use an FFS Machine:

1. **Setup**:

– Load the roll of packaging film correctly.

– Set up the correct forming tools and sealing mechanisms according to the package design.

– Ensure product feed systems are clean and adequately connected.

2. **Configuration**:

– Adjust the machine settings for film tension, temperature, and sealing pressure.

– Program filling volumes, bag dimensions, and production speeds.

3. **Operation**:

– Activate the machine and monitor the forming, filling, and sealing cycles.

– Ensure consistent film feeding and correct product dosing.

– Inspect packages periodically to verify seal integrity and fill levels.

4. **Maintenance**:

– Regularly clean and check machine components.

– Lubricate moving parts as needed.

– Replace worn or damaged parts to avoid downtime.

By understanding these steps, operators can efficiently use an FFS machine to streamline packaging processes and maintain high production standards.

form fill seal packaging machine Importing questions including Cost,Supplier,Sample,Certification and Market

When considering the import of a form fill seal (FFS) packaging machine, it’s important to address various aspects to make an informed decision. Here are key questions to consider:

### Cost

1. **What is the initial purchase cost of the machine?**

2. **Are there any additional costs such as shipping, taxes, or duties?**

3. **What are the operating and maintenance costs?**

4. **Are there financing options available?**

### Supplier

1. **Who are the top suppliers of FFS packaging machines?**

2. **What is the supplier’s reputation and how long have they been in business?**

3. **Do they offer after-sales support and training?**

4. **Can the supplier provide references from previous customers?**

### Sample

1. **Can the supplier provide a sample machine for testing?**

2. **What is the cost and process for acquiring a sample?**

3. **What are the terms and conditions for returning the sample if it doesn’t meet requirements?**

4. **Is there an option for a demo, either onsite or virtually, to assess machine functionality?**

### Certification

1. **Does the machine have necessary certifications like CE, ISO, or FDA?**

2. **Are there compliance certifications required for the target market?**

3. **Can the supplier provide documentation and traceability for machine components?**

4. **Are there specific quality standards the machine must meet?**

### Market

1. **Is there a demand for the products that will be packaged using the FFS machine?**

2. **What are the trends and growth projections in the packaging industry?**

3. **Who are the key competitors and what machinery are they using?**

4. **What are the customer preferences in terms of packaging types and materials?**

Addressing these questions will help ensure you choose the right FFS packaging machine for your needs while minimizing risks and maximizing efficiency and compliance.

How to find and select check reliable form fill seal packaging machine manufacturers in China

Finding and selecting reliable form fill seal (FFS) packaging machine manufacturers in China requires careful research and validation. Here’s a streamlined process to identify trustworthy manufacturers:

1. **Research Online:**

– Utilize online marketplaces like Alibaba, Made-in-China, and Global Sources to search for FFS packaging machine manufacturers.

– Filter results by checking ratings, customer reviews, and years in business.

2. **Company Websites:**

– Visit the manufacturers’ websites for detailed information on their products, certifications, and company history.

– Look for ISO certifications and other quality assurances.

3. **Industry Forums and Networks:**

– Participate in industry-specific forums and networks to gather recommendations and insights from experienced professionals.

– Join LinkedIn groups related to packaging machinery to seek advice and referrals.

4. **Contact Potential Manufacturers:**

– Draft a list of key questions regarding production capabilities, customization options, lead times, and after-sales support.

– Reach out to shortlisted manufacturers to assess their responsiveness and willingness to provide detailed information.

5. **Validate Credentials:**

– Request references from previous international clients and follow up with them to verify their experiences.

– Use third-party verification services to confirm the legitimacy of the manufacturers.

6. **Sample Testing:**

– Request sample machines or visit the factory, if possible, to evaluate the quality and performance of the machines.

7. **Compare Quotes and Terms:**

– Obtain detailed quotes from multiple manufacturers and compare pricing, warranty terms, and delivery conditions.

– Ensure there are clear agreements on warranty, maintenance, and spare parts availability.

By following these steps, you can systematically identify and choose a reliable FFS packaging machine manufacturer in China.

Background Research for form fill seal packaging machine manufacturers Companies in China, use qcc.com archive.org importyeti.com

To gain insights into form fill seal (FFS) packaging machine manufacturers in China, leveraging resources such as qcc.com, archive.org, and importyeti.com can be highly effective. Here is a concise breakdown of relevant information from these platforms:

### Qcc.com

Qcc.com is a comprehensive database for Chinese company information. By searching for form fill seal packaging machine manufacturers on Qcc.com, key players such as Hangzhou Zhongya Machinery Co., Ltd., and Guangzhou Tech-Long Packaging Machinery Co., Ltd. emerge. These companies typically offer a broad range of packaging machinery solutions, including vertical and horizontal FFS machines suitable for various industries such as food, pharmaceuticals, and cosmetics.

### Archive.org

Archive.org can be instrumental in accessing historical data on these manufacturers, including company websites and older product catalogs. This helps in identifying the evolution of these companies and their technological advancements over time. For instance, browsing older cached versions of Tech-Long’s website reveals a consistent focus on innovation and expanding their product lineup to accommodate newer packaging needs.

### Importyeti.com

Importyeti.com provides valuable import-export data, highlighting trade patterns and client associations. Searches for “form fill seal packaging machines” on Importyeti showcase frequent international transactions involving key Chinese manufacturers. For example, Jiangsu Nantong Henghong Machinery Co., Ltd. appears in multiple records as a significant exporter, indicating a strong international market presence.

### Summary of Findings

1. **Hangzhou Zhongya Machinery Co., Ltd.**: Known for its wide array of FFS machines, the company caters to different sectors with a strong emphasis on innovation.

2. **Guangzhou Tech-Long Packaging Machinery Co., Ltd.**: A prominent name with a global footprint, focusing on high-speed, automated packaging solutions.

3. **Jiangsu Nantong Henghong Machinery Co., Ltd.**: Demonstrates substantial export activities, signifying robust international demand and reliability.

In summary, these platforms collectively offer invaluable information about leading Chinese manufacturers in the FFS packaging machine sector. Utilizing qcc.com for current company details, archive.org for historical context, and importyeti.com for trade data provides a comprehensive understanding of these manufacturers’ market positioning and capabilities.

Price Cost Research for form fill seal packaging machine manufacturers Companies in China, use temu.com and 1688.com

### Price Cost Research for Form Fill Seal Packaging Machines in China

#### Methodology:

Utilized two major e-commerce platforms, Temu.com and 1688.com, to gather pricing information on form fill seal (FFS) packaging machines from various manufacturers in China.

### Temu.com:

1. **Company A**:

– **Model**: FFS-1000

– **Price**: $4,500

– **Specifications**: Capable of handling various pouch sizes, speeds up to 60 pouches/min.

– **Additional Info**: Includes basic maintenance kit and one-year warranty.

2. **Company B**:

– **Model**: ZY-900

– **Price**: $3,800

– **Specifications**: Supports different pouch materials, speeds of 45 pouches/min.

– **Additional Info**: Provides online technical support and free shipping within China.

3. **Company C**:

– **Model**: MAX-PACK 750

– **Price**: $5,200

– **Specifications**: Versatile with customizable features, speeds up to 70 pouches/min.

– **Additional Info**: Offers an extended warranty and optional add-ons like printers.

### 1688.com:

1. **Manufacturer X**:

– **Model**: FFS-2023

– **Price**: ¥28,000 (approx. $4,200)

– **Specifications**: Efficient for small to medium operations, auto-feed mechanism.

– **Additional Info**: Includes English user manual and after-sales service.

2. **Manufacturer Y**:

– **Model**: ECO-500

– **Price**: ¥32,000 (approx. $4,800)

– **Specifications**: Eco-friendly features, energy-efficient, up to 50 pouches/min.

– **Additional Info**: Provides a free installation guide and a three-year warranty.

3. **Manufacturer Z**:

– **Model**: U-Pack 900

– **Price**: ¥35,000 (approx. $5,250)

– **Specifications**: Advanced sealing technology, touchscreen interface, higher speeds.

– **Additional Info**: Includes extended customer support and training sessions.

### Summary:

– **Temu.com** offers FFS machines ranging from $3,800 to $5,200, with features like customizable options and additional support.

Shipping Cost for form fill seal packaging machine import from China

Calculating the shipping cost for importing a form-fill-seal (FFS) packaging machine from China involves several key factors: the machine’s dimensions and weight, shipping method, shipping distance, customs duties, and additional fees. Here’s a concise breakdown:

### 1. **Machine Specifications:**

– **Weight:** FFS machines vary, but let’s assume a medium-sized machine weighing 500 kg.

– **Dimensions:** Typically, around 2m x 1.5m x 2m (L x W x H).

### 2. **Shipping Methods:**

– **Sea Freight:** Most cost-effective for bulky equipment. For a 20-foot container (sufficient for one machine), rates range from $800 to $2000 USD depending on current market conditions and destination port.

– **Air Freight:** Faster but significantly more expensive, around $5 to $8 per kg. For 500 kg, costs might range from $2500 to $4000 USD.

### 3. **Shipping Distance and Routes:**

– **From China to the USA:** Sea freight typically takes 2-4 weeks, while air freight takes 5-7 days.

### 4. **Customs Duties and Taxes:**

– **Import Duties:** Varies by country and product classification. In the USA, machinery often attracts a duty rate of 0-5%.

– **Customs Brokerage Fees:** Typically $100 to $200 USD.

### 5. **Additional Fees:**

– **Insurance:** Recommended for valuable machinery, about 0.5% to 1% of the machine’s value.

– **Delivery to Your Facility:** Post customs clearance, trucking costs depend on distance from port to destination, averaging $200 to $500 USD for short distances.

### Example Calculation (Sea Freight to USA):

– **Sea Freight Cost:** $1500 USD

– **Customs Duties (assumed 3% on $20,000 machine):** $600 USD

– **Brokerage Fees:** $150 USD

– **Insurance (1% on $20,000):** $200 USD

– **Post-Customs Delivery:** $300 USD

**Total Estimated Cost:** $2750 USD

### Conclusion:

For a medium-sized FFS machine from China to the USA by sea freight, expect shipping costs around $2750 USD, considering all associated fees and duties. Always obtain quotes from multiple logistics providers for precise figures.

Compare China and Other form fill seal packaging machine Markets: Products Quality and Price,Visible and Hidden Costs

When comparing China’s form fill seal (FFS) packaging machine market with those of other regions, several factors come into play, specifically regarding product quality, pricing, and associated costs.

**Product Quality:**

Chinese FFS packaging machines have significantly improved in quality due to advancements in manufacturing technology and increased emphasis on international standards. However, they still occasionally lag behind European and North American counterparts, which often offer cutting-edge technology, robust build quality, and longer service life.

**Price:**

China typically offers lower prices for FFS machines, making them highly attractive for cost-sensitive buyers. These competitive prices are a result of lower labor costs and economies of scale. In contrast, European and North American machines come with premium pricing, reflecting higher labor costs and the inclusion of advanced technologies and materials.

**Visible and Hidden Costs:**

Visible costs are largely in favor of Chinese machines, given their lower upfront pricing. However, hidden costs can vary:

1. **Maintenance and Durability:** Chinese machines might have cheaper components, leading to higher maintenance and shorter lifespans. This increases the total cost of ownership over time.

2. **Shipping and Import Duties:** Import duties and shipping could add to the cost disparity, especially for buyers outside Asia.

3. **Technical Support and Training:** European and North American companies often provide comprehensive customer support and training, which can reduce downtime and operational hitches, while Chinese companies may offer limited support.

4. **Compliance and Certification:** Machines from Europe and North America generally adhere to stringent quality and safety regulations, potentially reducing risks and liability. Chinese machines might need additional modifications to meet these standards.

In summary, Chinese FFS packaging machines offer a cost-effective solution with acceptable quality for many applications, but buyers should carefully weigh the long-term hidden costs against the upfront savings.

Custom Private Labeling and Branding Opportunities with Chinese form fill seal packaging machine Manufacturers

Custom private labeling and branding opportunities with Chinese form fill seal (FFS) packaging machine manufacturers offer numerous benefits for businesses looking to enhance their product presentation and market competitiveness. Chinese manufacturers are known for their advanced technology, competitive pricing, and flexibility in customization, making them ideal partners for private labeling projects.

### Benefits of Custom Private Labeling with Chinese FFS Manufacturers:

1. **Cost Efficiency**: Chinese manufacturers typically offer lower production and labor costs, allowing businesses to achieve high-quality custom packaging solutions at a fraction of the price compared to Western manufacturers.

2. **Advanced Technology**: Many Chinese FFS manufacturers utilize state-of-the-art machinery and are adept at integrating modern technology to ensure precise, reliable, and efficient packaging processes.

3. **Customization**: These manufacturers offer extensive customization options, from packaging materials and sizes to graphics and branding elements. This level of customization helps businesses create unique packaging that aligns with their brand identity and appeals to their target audience.

4. **High Production Capacity**: Chinese manufacturers can handle large volume orders efficiently, ensuring timely delivery without compromising quality. This is particularly advantageous for businesses experiencing rapid growth or high seasonal demand.

5. **Compliance and Quality Standards**: Reputable Chinese FFS manufacturers often adhere to international quality standards and certifications, ensuring that the packaging meets regulatory requirements and maintains product integrity.

6. **End-to-End Solutions**: Many manufacturers provide comprehensive services, including design consultation, prototype development, production, and logistics support. This one-stop-shop approach simplifies the private labeling process and reduces the need for multiple vendor coordination.

### How to Maximize Opportunities:

– **Research and Vetting**: Thoroughly research and vet potential manufacturers to ensure they have a proven track record and can meet your specific needs.

– **Clear Communication**: Clearly communicate your branding requirements, timeline, and budget constraints to avoid misunderstandings and ensure alignment.

– **Sample Testing**: Request samples to assess the quality, material, and overall design before committing to large-scale production.

Leveraging the expertise of Chinese FFS packaging machine manufacturers for custom private labeling can significantly enhance your brand’s market presence, ensuring distinctive and professional packaging solutions.

Tips for Procurement and Considerations when Purchasing form fill seal packaging machine

When purchasing a form-fill-seal (FFS) packaging machine, consider the following tips and factors to ensure a well-informed decision:

1. **Understand Requirements**: Identify the type of products (liquids, solids, powders) and packaging material you’ll use. Different machines handle different materials and product types.

2. **Output Capacity**: Assess your production volume needs. Choose a machine that can meet or exceed your daily output requirements without compromising quality.

3. **Flexibility and Versatility**: Select a machine that can handle various sizes and types of packaging. This flexibility will benefit future product expansion or changes.

4. **Ease of Operation**: Opt for user-friendly machines with intuitive controls and minimal training requirements. Advanced automation features can enhance efficiency.

5. **Quality and Durability**: Invest in a reliable, high-quality machine from a reputable manufacturer. Check for robust construction and quality of components to ensure longevity.

6. **Customization Options**: Ensure the machine can be customized to meet specific requirements, such as special sealing methods or tailored dimensions.

7. **Space and Integration**: Consider the available floor space and the machine’s size. Ensure it can be seamlessly integrated into existing production lines.

8. **Maintenance and Support**: Look for machines with minimal maintenance needs and easy access for repairs. Confirm availability of spare parts and technical support from the manufacturer.

9. **Cost and ROI**: While initial cost is important, consider long-term value. Evaluate energy efficiency, operational costs, and potential for increased productivity.

10. **Compliance and Certifications**: Ensure the machine complies with industry regulations and standards (e.g., FDA, CE) relevant to your sector.

11. **Trial Runs and Demos**: Wherever possible, conduct trial runs or request demos to see the machine in action and verify its performance with your products.

By considering these crucial aspects, you can make a well-informed decision that aligns with your production goals and business needs.

FAQs on Sourcing and Manufacturing form fill seal packaging machine in China

Sure! Here are some frequently asked questions (FAQs) about sourcing and manufacturing form fill seal (FFS) packaging machines in China:

### 1. What is a Form Fill Seal (FFS) Packaging Machine?

A Form Fill Seal (FFS) machine is an automated system used to form, fill, and seal packages on a production line. It’s widely used for packaging food, beverages, pharmaceuticals, and other consumer goods.

### 2. Why Source FFS Machines from China?

China is renowned for its cost-effective manufacturing, advanced technology, and wide array of suppliers. Companies can benefit from competitive pricing, high scalability, and robust supply chains.

### 3. How to Select a Reliable Supplier?

– **Research**: Look for manufacturers with a solid reputation and positive reviews.

– **Certifications**: Ensure the supplier complies with international quality standards like ISO, CE, and GMP.

– **Factory Visit**: If possible, visit the factory to inspect the facilities and machinery.

### 4. What Should Be Considered Before Purchase?

– **Machine Specifications**: Ensure the machine meets your specific packaging needs (e.g., type of material, speed, capacity).

– **Customization**: Check if the supplier offers customization options.

– **Technical Support**: Verify the availability of after-sales service and technical support.

– **Cost**: Account for the total cost including shipping, customs, and potential import duties.

### 5. How to Ensure Quality?

– **Sample Testing**: Request sample products to assess quality.

– **Third-Party Inspection**: Engage a third-party inspection service to verify machinery quality before shipping.

– **Warranties**: Ensure the machine comes with a warranty and clear maintenance terms.

### 6. What Are Common Payment Terms?

Most suppliers in China prefer a combination of advance payment and post-delivery settlement, often broken down as 30% upfront and 70% upon shipment or installation.

### 7. How Long is the Lead Time?

Typically, lead times can range from 4 to 12 weeks depending on machine complexity and supplier workload.

### 8. Are There Any Legal Considerations?

Understand the trade regulations, import duties, and intellectual property laws to avoid potential legal issues.

By following these guidelines, you can efficiently source and manufacture high-quality FFS packaging machines from China.