Top 10 case erector with tape in China introduce,list main products and website if have

1. Jiaxing Ruide Packaging Machinery Co., Ltd. – This company offers a variety of case erectors with tape including automatic case erectors, semi-automatic case erectors, and fully automatic case erectors. Their main products also include case packers, case sealers, and carton erectors.

Website: https://ruidepack.com/

2. Hualian Machinery Group – Hualian Machinery Group Co., Ltd. is specialized in case erectors with tape, carton sealers, and other packaging machinery. They offer a wide range of case erectors suitable for different industrial needs.

Website: http://www.hualian.cn/

3. Qingdao Ausense Packing Equipment Co., Ltd. – This company provides case erectors with tape, automatic carton packing machines, and other packaging equipment. Their products are widely used in food, beverage, household and personal care, pharmaceutical, chemical, and automotive industries.

Website: https://www.ausense.com/

4. Wenzhou Zhonghuan Packaging Machinery Co., Ltd. – Zhonghuan Packaging Machinery offers automatic case erectors with tape, case sealing machines, and other packaging machinery. Their products are known for their high efficiency and reliability.

Website: https://www.chinazhonghuan.com/

5. Sengong Machinery Manufacturing Co., Ltd. – Sengong Machinery specializes in the production of fully automatic case erectors with tape, case packers, case sealers, and palletizers. They cater to various industries such as food, beverage, pharmaceutical, and chemical.

Website: http://www.sengong.net.cn/

6. Shanghai Joygoal Food Machinery Co., Ltd. – Joygoal Food Machinery provides case erectors with tape, carton and box sealing machines, and other packaging solutions. They serve the food and beverage, pharmaceutical, and cosmetic industries.

Website: https://www.shjoygoal.com/

7. Qingdao Feifan Packing Machinery Co., Ltd. – Feifan offers case erectors with tape, carton sealing machines, and wrapping machinery. They cater to a wide range of industries including food, beverage, and logistics.

Website: https://www.feifanpack.com/

8. Qingdao Fusheng Sirui Automatic Equipment Co., Ltd. – Fusheng Sirui specializes in case erectors with tape, case packers, and packaging lines. Their products are known for their durability and high performance.

Website: http://www.siruimachine.com/

Types of case erector with tape

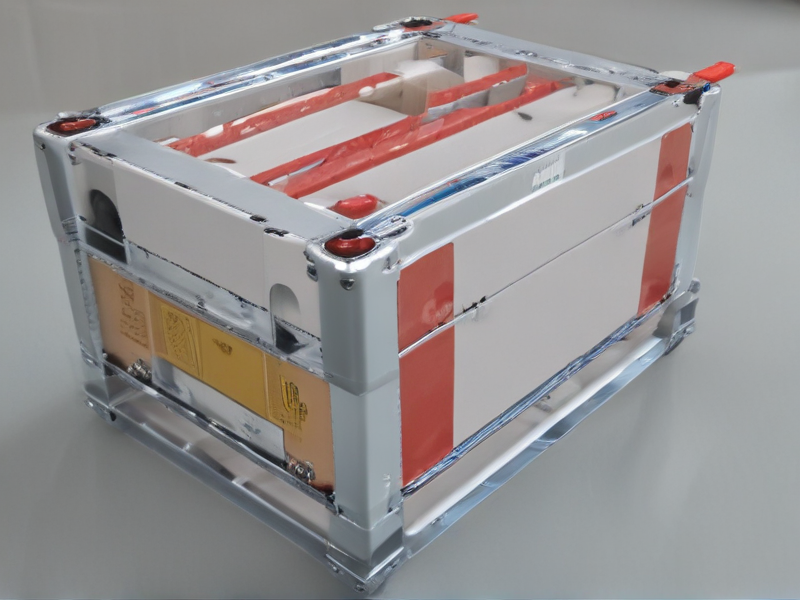

Case erectors with tape are machinery designed to automatically fold and seal cardboard boxes using adhesive tape. There are several types of case erectors with tape, each with its own unique features and benefits.

1. Random case erectors: Random case erectors are able to automatically adjust to different sizes and shapes of boxes, making them ideal for applications where multiple box sizes are used. These machines can quickly and efficiently seal boxes of varying dimensions without the need for manual adjustments.

2. Uniform case erectors: Uniform case erectors are designed for applications where only one size of box is used. These machines are more streamlined in their design and are optimized for high-volume production of boxes of a consistent size.

3. Side belt case erectors: Side belt case erectors use two conveyor belts on the sides of the machine to feed the boxes through the case erector and fold and seal the flaps with tape. This type of case erector is commonly used in medium to high-speed packaging lines.

4. Top belt case erectors: Top belt case erectors utilize a conveyor belt on the top of the machine to drive the boxes through the erector and seal them with tape. This design is often preferred for applications where boxes may be heavier or where the bottom of the box needs to remain flat.

Overall, case erectors with tape offer increased efficiency, speed, and consistency in the packaging process. They are essential equipment for industries that require a high volume of boxed products to be shipped or stored. By automating the box sealing process, these machines can help companies save time and labor costs while ensuring that their products are securely packaged.

Pros and Cons of Using case erector with tape

Case erectors with tape offer several benefits for companies in need of packaging solutions. These machines are designed to efficiently and accurately form and seal cases, which can ultimately increase productivity and reduce labor costs. By automating the process of erecting and taping cases, businesses can save time and improve consistency in their packaging operations. This is especially beneficial for companies with high-volume production and packaging needs.

With the use of a case erector with tape, companies can also minimize the risk of ergonomic injuries associated with manual case forming and taping. This can lead to a safer work environment and lower the likelihood of workplace accidents. Additionally, automated case erecting and taping can help improve the overall appearance of the packaging, providing a more professional and uniform look for the products, which can positively impact brand perception and customer satisfaction.

However, there are also drawbacks to consider when using case erectors with tape. These machines require regular maintenance and upkeep to ensure they continue to function properly. This can result in additional costs and downtime for businesses. Furthermore, the initial investment in purchasing a case erector with tape may be high, and companies will need to consider the return on investment over time. Additionally, the machines may have some limitations in terms of the types and sizes of cases they can handle, which can be a constraint for companies with diverse packaging needs.

In conclusion, the use of case erectors with tape can provide various advantages for companies looking to streamline their packaging process and improve efficiency. However, it is important for businesses to carefully assess their specific needs and weigh the potential benefits against the associated costs and limitations before deciding to invest in this technology.

case erector with tape Reference Specifications (varies for different product)

The case erector with tape is a versatile machine used in various industries for automating the process of erecting and sealing corrugated cardboard cases. The machine is outfitted with a tape sealing mechanism and can handle different types and sizes of cases, depending on the specific product requirements. The following are the reference specifications for a case erector with tape:

1. Cardboard Case Size Range: The machine should be able to accommodate a range of case sizes, including width, length, and height, to meet the diversified requirements of different products.

2. Speed and Productivity: The machine should have a high output capacity, with a specified number of cases per minute, to ensure efficient and rapid processing of products.

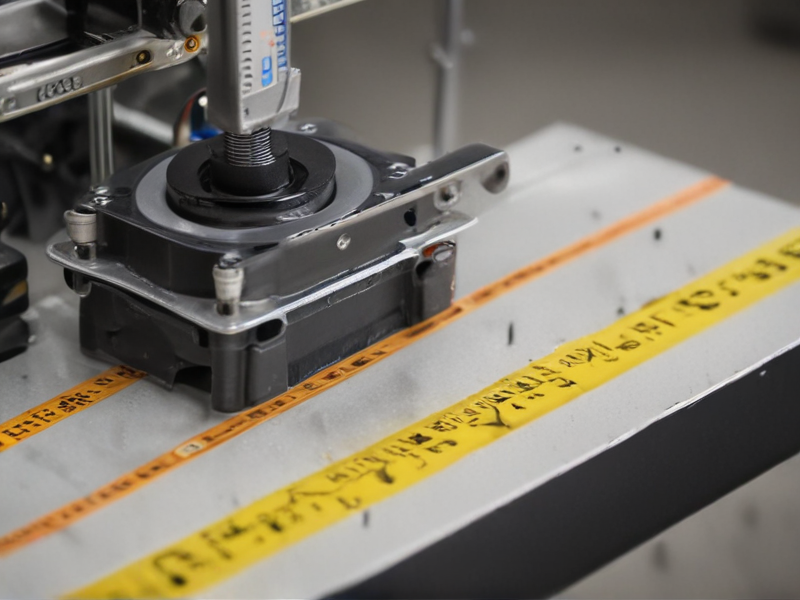

3. Tape Sealing Mechanism: The machine should have a reliable and efficient tape sealing mechanism that can apply adhesive tape to the bottom flaps of the cases with precision and consistency.

4. Control System: The machine should have a user-friendly control panel with programmable settings for adjusting the case size, speed, and other parameters, to accommodate different products.

5. Construction and Durability: The machine should be constructed using robust materials and components to ensure durability and longevity, even under demanding operational conditions.

6. Safety Features: The machine should be equipped with safety measures, such as emergency stop buttons, protective guards, and safety interlocks, to protect operators and prevent accidents.

7. Power Requirements: The machine should have specific electrical and power requirements, including voltage, phase, and frequency, to ensure compatibility with the facility’s power supply.

Overall, the case erector with tape should meet the specific application needs of the product, while providing consistent and reliable performance, high efficiency, and operator safety. It’s important to consider these reference specifications when selecting a case erector with tape for a particular product or industry.

Applications of case erector with tape

A case erector with tape is a machine used to automatically form and seal corrugated boxes using tape. This efficient and cost-effective equipment is widely used in various industries for packaging applications.

In the food and beverage industry, case erectors with tape are used to efficiently prepare boxes for packaging finished products. These machines can handle a wide variety of box sizes and can quickly and consistently form and seal boxes, increasing productivity and reducing labor costs. This is especially useful in high-volume production environments where speed and efficiency are essential.

In the e-commerce and fulfillment industry, case erectors with tape are used to prepare boxes for shipping orders. These machines can handle the high volume of orders and various box sizes required for shipping, thereby improving order fulfillment efficiency and reducing shipping costs. In addition, the consistent and secure sealing provided by the tape ensures that the products are well-protected during transit.

In the pharmaceutical and medical device industry, case erectors with tape are used to prepare boxes for packaging and shipping delicate and sensitive products. The reliable sealing offered by these machines ensures the safety and integrity of the products during transportation, which is crucial for maintaining product quality and compliance with regulatory standards.

Other industries such as automotive, electronics, and consumer goods also use case erectors with tape for their packaging needs. These machines offer a reliable and consistent method for forming and sealing boxes, which is essential for protecting the products during storage and transportation.

Overall, the applications of case erectors with tape are wide-ranging and essential for various industries to improve packaging efficiency, reduce labor costs, and ensure the safe and secure transportation of products.

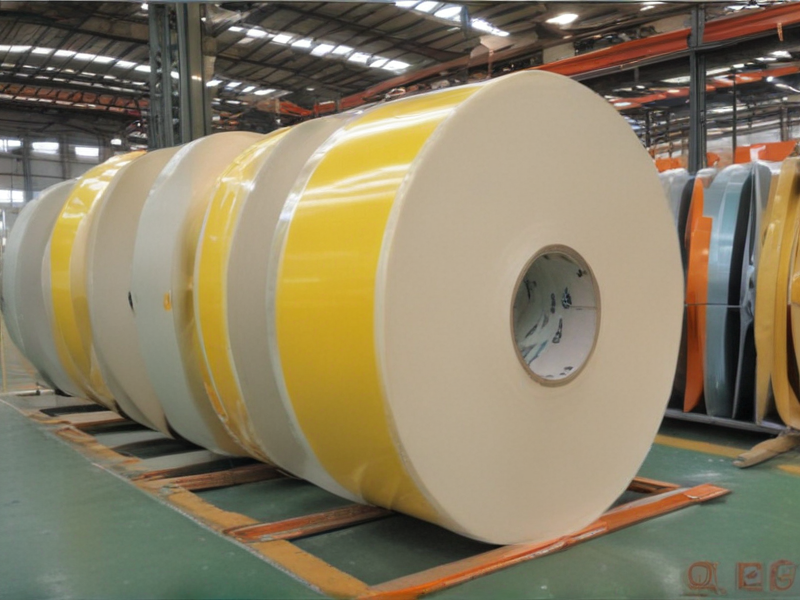

Material of case erector with tape

A case erector with tape is commonly used in industrial and warehouse settings to automate the process of forming and sealing cardboard boxes. These machines are designed to increase efficiency and accuracy in packaging operations, allowing businesses to handle higher volumes of products with minimal manual labor.

The material of the case erector with tape typically includes a combination of durable metal and high-quality plastic components. The external frame and structural elements are often made of stainless steel or aluminum, providing the necessary sturdiness and support for its operations. These materials are chosen for their strength, resistance to rust and corrosion, and ability to withstand the wear and tear of daily use.

In addition to the metal components, the case erector with tape also incorporates high-quality plastic parts for various functions. The tape dispensing mechanism, for example, is often made of robust plastic materials that can endure the demands of continuous tape application. The cutting and sealing mechanisms may also feature precision-engineered plastic components for efficient and reliable box sealing.

The combination of metal and plastic materials in the construction of a case erector with tape ensures that the machine is durable, long-lasting, and capable of consistently delivering high-performance results. The use of these materials also contributes to the overall safety, reliability, and ease of maintenance of the equipment.

Overall, the material composition of a case erector with tape is carefully selected to meet the demands of modern packaging operations, providing a reliable and efficient solution for forming and sealing cardboard boxes in a variety of industrial and commercial settings.

Quality Testing Methods for case erector with tape and how to control the quality

There are several quality testing methods that can be used for a case erector with tape to ensure its performance and effectiveness.

1. Visual inspection: Conduct a visual inspection of the case erector to check for any visible defects, such as misaligned components or worn out parts.

2. Tape adhesion test: Perform a tape adhesion test to ensure that the tape is properly sealing the cases. This can be done by applying pressure to the taped seal and checking for any signs of peeling or lifting.

3. Speed test: Test the case erector’s speed to ensure that it is able to meet the production requirements. This can be done by running a simulated production run and tracking the time it takes to erect and seal a certain number of cases.

4. Maintenance check: Regularly inspect and maintain the case erector to prevent any potential issues from arising. This includes checking for worn out parts, lubricating moving components, and conducting routine maintenance tasks.

To control the quality of the case erector with tape, it is important to establish a regular maintenance schedule and adhere to it strictly. This will help prevent any potential breakdowns or issues that could affect the performance of the machine. Additionally, conducting regular quality testing using the methods mentioned above will help identify any issues early on and address them promptly. By ensuring proper maintenance and conducting quality testing, the overall performance and efficiency of the case erector with tape can be maintained at a high level.

The Work Process and how to use case erector with tape

A case erector is a machine designed to automatically form and seal corrugated cardboard boxes. It is commonly used in industries that require high volume packaging, such as food and beverage, pharmaceutical, and manufacturing. The process of using a case erector with tape involves several steps to ensure efficient and reliable operation.

First, the operator needs to ensure that the case erector is properly set up and calibrated according to the specific box dimensions and tape requirements. This may involve adjusting the machine’s settings, such as conveyor speed and tape length, and loading the appropriate tape roll into the dispenser.

Once the case erector is ready, the operator can begin the process by feeding flat cardboard box blanks into the machine’s magazine or hopper. The machine will then automatically pick and place the box blanks onto the forming mandrel, where they are folded and sealed using tape.

During this process, it is important for the operator to monitor the machine’s performance and make any necessary adjustments to ensure that the boxes are properly formed and sealed. This may involve adjusting the tape position or tension, clearing any jammed box blanks, or replenishing the tape supply as needed.

After the boxes have been formed and sealed, they can be transported to the next stage of the packaging process, such as filling and sealing or palletizing. The use of a case erector with tape helps to streamline the packaging process, improve productivity, and reduce the risk of manual errors.

In conclusion, using a case erector with tape involves setting up the machine, feeding the box blanks, monitoring the operation, and ensuring that the formed boxes are properly sealed. By following these steps, operators can effectively use a case erector to improve the efficiency and reliability of their packaging operations.

case erector with tape Importing questions including Cost,Supplier,Sample,Certification and Market

1) Cost:

– What is the cost of the case erector with tape?

– Are there any additional fees or charges that we should be aware of?

– Is there a bulk discount available for large orders?

2) Supplier:

– Who is the supplier of the case erector with tape?

– Can you provide information about the company and their reputation in the industry?

– Are they able to fulfill orders in a timely manner?

3) Sample:

– Is it possible to receive a sample of the case erector with tape before making a purchase?

– What is the process for obtaining a sample?

– Are there any costs associated with receiving a sample?

4) Certification:

– Has the case erector with tape been certified or tested for quality and safety standards?

– Can you provide documentation or proof of any certifications?

– Are there any specific industry standards or regulations that the product adheres to?

5) Market:

– What is the current market demand for the case erector with tape?

– Are there any specific industries or regions where this product is particularly popular?

– Are there any unique selling points or features that set this product apart in the market?

It is essential to gather information about the cost, supplier, sample availability, certification, and market demand before making a purchasing decision for the case erector with tape. This will help ensure that the product meets quality standards, is competitively priced, and is well-suited to the intended market. Additionally, obtaining a sample can provide firsthand experience with the product, allowing for a more informed decision. A reliable and reputable supplier will be able to provide transparent information about the product, including any certifications and market insights.

How to find and select check reliable case erector with tape manufacturers in China

When looking for reliable case erector with tape manufacturers in China, there are several steps you can take to find and select the best one for your needs.

First, conduct thorough research online to find a list of potential manufacturers. Look for manufacturer directories, industry trade shows, and B2B platforms to find a comprehensive list of manufacturers.

Next, narrow down your list by considering factors such as the manufacturer’s experience, reputation, and product quality. Look for customer reviews and testimonials to assess the manufacturer’s reliability.

Once you have created a shortlist of potential manufacturers, reach out to them and request for product samples, pricing, and lead times. Ensure that the manufacturer has the capability to meet your production requirements and can provide the level of service and support that you need.

It is also important to consider the manufacturer’s certifications and quality control processes to ensure that their products meet your standards.

When selecting a manufacturer, consider factors such as their ability to meet your specific requirements, their communication and support, and their overall reliability.

By following these steps, you can find and select a reliable case erector with tape manufacturer in China that meets your needs and requirements.

Background Research for case erector with tape manufacturers Companies in China, use qcc.com archive.org importyeti.com

When looking for case erector with tape manufacturers in China, companies can utilize resources such as qcc.com, archive.org, and importyeti.com to conduct background research. These platforms provide valuable information about potential manufacturers, including their company profile, business scope, production capacity, and certifications.

Qcc.com is a comprehensive online platform that offers company information, news, and industry analysis. This website allows users to search for manufacturers and suppliers in China, providing contact details and company background. By using qcc.com, companies can gather in-depth information about potential case erector with tape manufacturers, including their product offerings and manufacturing capabilities.

Archive.org is another useful tool for conducting background research on manufacturers in China. This platform allows users to access historical web page snapshots, allowing companies to track the development and changes within a manufacturer’s business. By reviewing previous iterations of a manufacturer’s website, companies can gain insight into their evolution, product range, and market presence.

Importyeti.com is a database that compiles customs data to provide import and export insights for businesses. This platform allows users to search for specific products, including case erector with tape, and identify the manufacturers and suppliers associated with these products. By using importyeti.com, companies can access valuable data about the manufacturing activities of potential suppliers in China, including their production volume and export destinations.

By leveraging these resources, companies can gather crucial background information about case erector with tape manufacturers in China. Conducting thorough research using qcc.com, archive.org, and importyeti.com can help businesses make informed decisions when selecting a reliable and capable manufacturer for their needs.

Price Cost Research for case erector with tape manufacturers Companies in China, use temu.com and 1688.com

In order to find the price cost for case erector with tape manufacturers in China, we can use online platforms such as temu.com and 1688.com. These platforms provide access to a wide range of manufacturers and suppliers, making it easier to compare prices and find the best deals.

When using temu.com, it is important to specify the product requirements such as the type of case erector and tape specifications. From there, you can browse through the listed manufacturers and suppliers to find the best options that meet your needs. You can also communicate directly with the manufacturers to negotiate prices and get a better understanding of the product quality and production capabilities.

Similarly, 1688.com is another platform where you can search for case erector with tape manufacturers in China. By entering specific keywords related to your product requirements, you can access a list of manufacturers and suppliers. You can then compare prices, product specifications, and customer reviews to make an informed decision.

When conducting research on these platforms, it is important to consider factors such as production capacity, quality control measures, and lead times. Additionally, it is advisable to request quotes from multiple manufacturers to ensure that you are getting the best possible price for the product.

By utilizing temu.com and 1688.com, you can efficiently research and compare prices for case erector with tape manufacturers in China, helping you to find the most cost-effective and reliable supplier for your business needs.

Shipping Cost for case erector with tape import from China

The shipping cost for importing a case erector with tape from China can vary based on several factors such as the size and weight of the equipment, the shipping method chosen, and the distance between the origin and destination.

One of the most common shipping methods for importing goods from China is sea freight. The cost of sea freight is usually calculated based on the volume or weight of the shipment. For a case erector with tape, which is likely to be heavy and bulky, the cost of sea freight may be significant.

Another factor to consider is the shipping terms agreed upon with the supplier in China. If the supplier is responsible for arranging the shipping, they may offer a more competitive rate through their existing relationships with freight forwarders. However, if the buyer is responsible for arranging the shipping, they would need to factor in additional costs for hiring a freight forwarder and handling the paperwork and customs clearance.

Furthermore, import duties and taxes may also impact the overall cost of importing the case erector with tape. It is important to research and understand the applicable duties and taxes before finalizing the purchase to avoid any unexpected costs.

Given these considerations, it is advisable to obtain quotes from multiple freight forwarders or shipping companies to compare the shipping costs and services offered. Additionally, working with a logistics specialist who has experience with importing machinery from China can help navigate the complexities of international shipping and ensure a smooth and cost-effective process. By carefully planning and negotiating the shipping arrangements, it is possible to import the case erector with tape from China while staying within the specified budget.

Compare China and Other case erector with tape Markets: Products Quality and Price,Visible and Hidden Costs

China is known for producing a wide range of case erectors with tape that vary in quality and price. The products from China are generally lower in price compared to those from other markets, and this is one of the key factors that has contributed to China’s dominance in the global case erector with tape market. However, the quality of Chinese case erectors with tape varies, and there are concerns about the reliability and durability of some of these products.

On the other hand, other markets, such as the United States and Europe, are known for producing higher quality case erectors with tape. The products from these markets are often more reliable and durable, and they come with a higher price tag. This higher price, however, reflects the superior quality and performance of these products.

When comparing the visible and hidden costs of case erectors with tape from China and other markets, it is important to consider factors such as maintenance, repairs, and downtime. While Chinese products may have a lower upfront cost, they may end up costing more in the long run due to higher maintenance and repair costs. In contrast, products from other markets may have a higher upfront cost, but they are often more reliable and require less maintenance, ultimately leading to lower total costs over time.

In conclusion, while China dominates the case erector with tape market in terms of price and availability, the quality and long-term costs of their products may be a concern for some customers. Other markets, on the other hand, are known for producing higher quality and more reliable products, but at a higher price. When making a purchasing decision, it is important for customers to carefully consider their specific needs and weigh the upfront cost against the long-term costs and benefits of the different options available in the market.

Custom Private Labeling and Branding Opportunities with Chinese case erector with tape Manufacturers

Are you a retailer or distributor looking for custom private labeling and branding opportunities for Chinese case erector with tape manufacturers? Look no further! Our manufacturing partners in China offer private labeling and branding services, allowing you to customize the products with your own logo, designs, and packaging.

By leveraging these services, you can create a unique and exclusive product line that sets you apart from competitors and resonates with your target market. Whether you’re looking to launch a new brand or expand your existing product line, private labeling and branding can help you establish a strong brand identity and build customer loyalty.

Our manufacturing partners have the capabilities to produce high-quality case erectors with tape that meet your specifications and branding requirements. They can work with you to develop custom packaging designs, color schemes, and product features that align with your brand image and positioning.

In addition to private labeling and branding, our manufacturing partners can also provide OEM and ODM services, allowing you to customize the product itself to meet the unique needs of your customers.

With low minimum order quantities and competitive pricing, private labeling and branding with our Chinese case erector with tape manufacturers is an affordable and effective way to bring your brand to market.

Contact us today to learn more about our private labeling and branding opportunities with Chinese case erector with tape manufacturers. Let us help you create a branded product line that resonates with your customers and drives business growth.

Tips for Procurement and Considerations when Purchasing case erector with tape

When purchasing a case erector with tape, it is important to consider a few key factors to ensure that you are getting the right machine for your needs. Here are some tips and considerations for procurement:

1. Capacity and Speed: Consider the production capacity and speed of the case erector to ensure it meets your production requirements. Determine the number of cases you need to erect and seal per minute and choose a machine that can handle your volume efficiently.

2. Case Size and Weight: Ensure that the case erector can handle the sizes and weights of the cases you will be using. Some machines are designed for specific case dimensions and weight limits, so it’s important to choose a model that can accommodate your specific packaging needs.

3. Tape Application: Evaluate the quality of the tape application system on the case erector. Look for a machine that can consistently and securely apply tape to the bottom and top flaps of the cases to ensure proper sealing during transit and storage.

4. Ease of Use and Maintenance: Consider the user-friendliness of the machine and the ease of maintenance. Look for a case erector with intuitive controls and easy access for maintenance and adjustments to minimize downtime and reduce the need for specialized training.

5. Integration with Packaging Line: If you have an existing packaging line, consider how the case erector will integrate with your current equipment. Ensure that the machine can easily be integrated into your production line without significant modifications or disruptions.

6. Supplier Reputation and Support: Choose a reputable supplier with a track record of providing reliable and durable case erectors. Look for a supplier that offers excellent customer support, including training, installation, and ongoing maintenance services.

By considering these factors, you can ensure that you select the right case erector with tape for your packaging needs, ultimately improving efficiency and productivity in your operations.

FAQs on Sourcing and Manufacturing case erector with tape in China

1. What are the benefits of sourcing a case erector with tape from China?

Sourcing a case erector with tape from China can provide cost savings due to lower manufacturing and labor costs. Chinese manufacturers also have extensive experience in producing packaging machinery, and many offer customization and customization options to suit specific business needs.

2. Are there any potential challenges in sourcing from China?

Some potential challenges when sourcing from China include language and communication barriers, quality control issues, longer lead times and shipping costs. It’s important to conduct thorough due diligence and establish a solid relationship with a reliable supplier.

3. What are the key considerations when selecting a manufacturer in China?

When selecting a manufacturer in China, it’s important to consider their experience and reputation in producing case erectors with tape. Look for a manufacturer with a strong track record, certifications, and a commitment to quality control. It’s also essential to understand their production capabilities, lead times, and the ability to meet specific customization requirements.

4. How can I ensure quality control when sourcing from China?

Quality control can be ensured by conducting thorough supplier audits, inspecting production facilities, and implementing product testing protocols. It’s essential to communicate clear expectations to the manufacturer and establish a quality control process that includes regular inspections and testing.

5. What are the shipping options for importing a case erector with tape from China?

There are several shipping options for importing machinery from China, including air freight, sea freight, and express courier services. Each option has its advantages and considerations, such as cost, transit time, and the size of the shipment.

In sourcing and manufacturing a case erector with tape from China, thorough planning and due diligence are essential to ensure a successful partnership with a reliable supplier and the delivery of high-quality equipment.