Top 10 case labeling system in China introduce,list main products and website if have

1. **Zebra Technologies**

– **Main Products:** Industrial printers, mobile printers, print engines, RFID printers

– **Website:** [Zebra Technologies China](https://www.zebra.com/cn/zh.html)

2. **Honeywell**

– **Main Products:** Barcode printers, industrial label printers, mobile printing systems

– **Website:** [Honeywell China](https://www.honeywell.com.cn)

3. **Brother**

– **Main Products:** Label printers, portable label printers, industrial labeling machines

– **Website:** [Brother China](https://www.brother.cn)

4. **SATO**

– **Main Products:** Industrial printers, RFID solutions, label design software

– **Website:** [SATO China](http://www.satoasiapacific.com/china/)

5. **TSC Auto ID Technology**

– **Main Products:** Industrial barcode printers, desktop printers, mobile printers

– **Website:** [TSC China](https://www.tscprinters.cn)

6. **Datalogic**

– **Main Products:** Automatic identification systems, barcode printing solutions

– **Website:** [Datalogic China](https://www.datalogic.com/chn/home-chn.html)

7. **Godex**

– **Main Products:** Industrial barcode printers, desktop label printers

– **Website:** [Godex China](http://www.godexintl.com/ch)

8. **Postek**

– **Main Products:** Industrial barcode printers, desktop printers, barcode printer accessories

– **Website:** [Postek](http://www.postek.com.cn/)

9. **Gprinter**

– **Main Products:** Barcode printers, POS printers, label printers

– **Website:** [Gprinter](http://www.gprinter.cn/)

10. **Jolimark**

– **Main Products:** Label printers, POS printers, commercial printers

– **Website:** [Jolimark](http://www.jolimark.com/)

These companies are top players in the label printing and case labeling industry in China, offering a range of products from industrial printers to mobile solutions.

Types of case labeling system

Case labeling systems are essential in packaging and distribution processes, ensuring that products are correctly identified and tracked. Here are some common types:

1. **Print and Apply Labeling Systems**:

– **Description**: These systems print labels on-demand and apply them directly to cases.

– **Uses**: Ideal for applications requiring dynamic information, like variable lot numbers or shipping addresses.

– **Advantages**: High flexibility and accuracy.

2. **Pre-Printed Labeling Systems**:

– **Description**: Labels are printed in advance and manually or automatically applied to cases.

– **Uses**: Suitable for uniform or static information.

– **Advantages**: Cost-effective for standardized labels.

3. **In-Line Printing Systems**:

– **Description**: Uses thermal or inkjet printers integrated into the conveyor system to print directly on cases.

– **Uses**: For real-time need and minimal handling.

– **Advantages**: Eliminates label inventory and reduces labor.

4. **High-Resolution Inkjet Systems**:

– **Description**: Prints high-quality text, graphics, and barcodes directly onto the cases as they move on the conveyor.

– **Uses**: Suitable for large volumes and detailed printing needs.

– **Advantages**: High speed, minimal disruptions.

5. **Laser Coding Systems**:

– **Description**: Uses laser to etch information directly onto cases.

– **Uses**: Permanent coding for high durability.

– **Advantages**: Maintenance-free, no ink or labels needed.

6. **Automatic Label Applicators**:

– **Description**: Automatically applies pre-printed labels to cases as they pass through the production line.

– **Uses**: High-speed operations with pre-printed labels.

– **Advantages**: Efficiency in large-scale labeling.

Each system has its specific applications, with considerations including production volume, label information variability, and overall cost. By understanding these systems, businesses can choose the most effective solution for their needs.

Pros and Cons of Using case labeling system

**Pros of Case Labeling Systems:**

1. **Efficiency**: Simplifies tracking and categorization, ensuring quick access to information.

2. **Accuracy**: Minimizes errors in identifying and handling cases, improving data integrity.

3. **Scalability**: Accommodates a growing volume of cases efficiently as the system expands.

4. **Compliance**: Facilitates adherence to regulatory requirements by maintaining organized records.

5. **Analytical Insights**: Eases data analysis by grouping similar cases, enabling better decision-making.

**Cons of Case Labeling Systems:**

1. **Initial Setup Cost**: Can be expensive and time-consuming to implement.

2. **Complexity**: May require training for employees to understand and use effectively.

3. **Maintenance**: Needs regular updates and maintenance, which can be resource-intensive.

4. **Over-reliance**: Excessive dependence on the system might reduce flexibility in unusual situations.

5. **Data Security**: Requires robust security measures to protect sensitive information from breaches.

Overall, a case labeling system can significantly enhance the organization and management of cases, but one must weigh the benefits against the costs and potential complexities of implementation and maintenance.

case labeling system Reference Specifications (varies for different product)

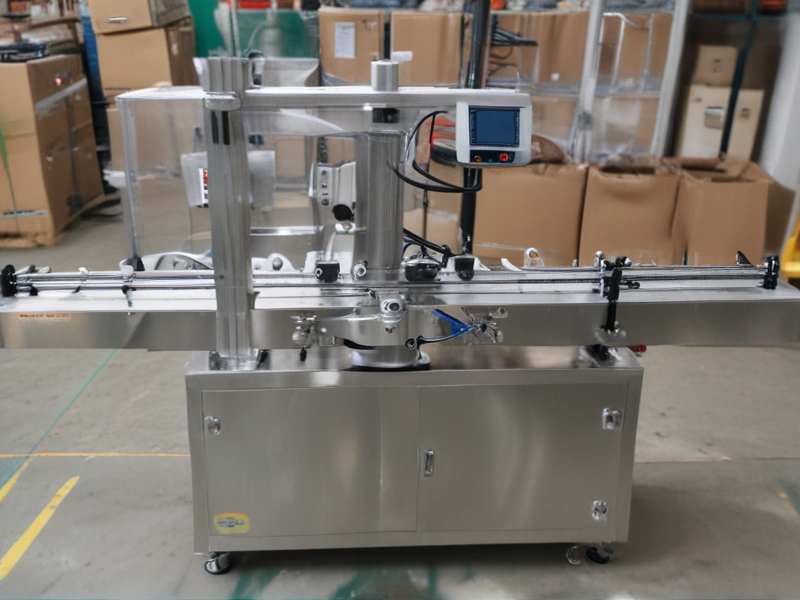

A Case Labeling System, designed to affix labels accurately and efficiently on a variety of products, must accommodate different reference specifications to ensure versatility and reliability. Here are general key specifications to consider:

1. **Label Types**: Compatibility with various label sizes (from 1”x1” to 6”x8”) and materials (paper, synthetic, etc.). Ensure system supports barcode, QR code, and RFID labels for diversified applications.

2. **Speed and Throughput**: Capable of labeling up to 120 cases per minute (dependent on label size and product). Adjustable speed settings to match production line requirements.

3. **Placement Accuracy**: Precision placement with a tolerance range of ±0.5 mm, ensuring correct label positioning every time. Features real-time adjustment capabilities for variations.

4. **Print Engine Compatibility**: Integration with leading print engines (e.g., Zebra, SATO, Honeywell) for on-demand printing, ensuring high-resolution prints (300-600 dpi).

5. **Product Range**: Accommodates various product dimensions and shapes. Adjustable guides and sensors for seamless adaptation from small to large cases.

6. **User Interface**: Intuitive touchscreen interface for easy operation, fast setup, and troubleshooting. Multilingual support and customizable user settings.

7. **Data Handling and Connectivity**: Supports network connectivity for real-time data exchange and integrated ERP systems. USB, Ethernet, and wireless options for versatile connectivity. Compliance with standard communication protocols.

8. **Durability and Construction**: Robust, stainless-steel construction suitable for harsh manufacturing environments. IP-rated components for dust and water resistance.

9. **Safety and Compliance**: Safety features including emergency stop, interlock systems, and compliance with regional safety standards (CE, UL).

10. **Maintenance and Support**: Easy-access design for maintenance and cleaning. Availability of online monitoring and diagnostics, with 24/7 support options.

By adhering to these specifications, a case labeling system ensures operational efficiency, reduces downtime, and maintains high standards of product identification and traceability across various industries.

Applications of case labeling system

A case labeling system is an integral part of modern industrial operations, ensuring that products are correctly identified, tracked, and managed across various stages of production and distribution. Here are some primary applications:

1. **Inventory Management**: An efficient case labeling system simplifies inventory tracking, facilitates real-time updates, and minimizes errors. This is crucial for maintaining optimal stock levels and managing reorder cycles.

2. **Supply Chain Efficiency**: Labels with barcodes or RFID tags enable faster processing at different supply chain points, enhancing transparency and traceability. This ensures timely delivery and reduces bottlenecks.

3. **Regulatory Compliance**: Industries such as pharmaceuticals, food, and automotive must adhere to stringent regulations regarding product information. Case labeling systems help maintain compliance by ensuring accurate and consistent labeling according to regulatory requirements.

4. **Quality Control**: Accurate labeling is essential for quality assurance. By linking products to specific batches or production lots, companies can trace defects, manage recalls more efficiently, and maintain high quality standards.

5. **Customer Service**: Case labeling ensures that customers receive the correct products with all necessary information, such as expiration dates and usage instructions, thereby improving customer satisfaction and trust.

6. **Automation and Efficiency**: In automated environments, case labeling systems integrate with other machinery and software to streamline operations, reduce manual interventions, and enhance overall productivity.

7. **Marketing and Branding**: Custom labels can enhance product visibility and brand recognition on retail shelves. By incorporating branding elements, companies can differentiate their products and appeal more directly to consumers.

8. **Data Collection and Analytics**: Labels facilitate the collection of critical data points, enabling companies to analyze trends, forecast demand, and make data-driven decisions.

In summary, case labeling systems are vital across several domains, bolstering operational efficiency, regulatory compliance, quality control, and customer satisfaction. Their integration into various industrial processes helps companies maintain competitive advantage and operational excellence.

Material of case labeling system

Case labeling systems are essential in logistics, warehousing, and manufacturing environments for the identification and tracking of products. The material composition of these systems is a crucial factor for their durability, functionality, and cost-efficiency. Below are the typical materials used in various components of case labeling systems:

1. **Housing:**

– **Metals:** Often made of stainless steel or aluminum for strength, durability, and resistance to corrosion. Stainless steel is preferred in harsh environments due to its robustness.

– **Plastics:** High-impact polymers such as ABS (Acrylonitrile Butadiene Styrene) or polycarbonate are used for lightweight and cost-effective solutions while maintaining good durability.

2. **Print Head Mechanism:**

– **Ceramics and Metals:** The print head mechanism usually involves materials like ceramics or specialized metals that can withstand high temperatures and pressures during the printing process.

3. **Conveyor Systems:**

– **Steel and Rubber:** Conveyor belts are typically made of rubber, while the structural parts are constructed from steel for heavy-duty support and longevity.

4. **Sensors and Electronics:**

– **Silicon and Other Semiconductor Materials:** Advanced sensors and electronic components are made from silicon and other semiconductor materials, ensuring precise functioning and reliability.

– **Encasements:** Often encased in plastic or metal housings to protect against environmental factors like dust, moisture, and impact.

5. **Label Applicators:**

– **Composite Materials:** These often consist of composite materials combining metals and plastics for lightweight yet durable operation.

– **Rollers and belts:** Typically crafted from rubber or other non-slip materials to ensure accurate label application.

6. **Control Panels:**

– **Plastic and Glass:** The interface, including buttons and screens, is usually made from durable plastics and toughened glass for long-term use.

By choosing appropriate materials, manufacturers ensure that case labeling systems are reliable, robust, and capable of operating in various industrial conditions, thus meeting the demands of modern logistics and manufacturing processes.

Quality Testing Methods for case labeling system and how to control the quality

To ensure the quality of a case labeling system, several testing methods and quality control techniques can be employed:

1. **Automated Inspection**:

– **Vision Systems**: Use cameras and image recognition software to verify label presence, alignment, and legibility.

– **Barcode Scanners**: Automatically read and verify barcodes for accuracy.

2. **Functional Testing**:

– **Dry Runs**: Test the labeling system without actual products to ensure mechanical parts are functioning correctly.

– **Unit Testing**: Conduct individual component tests to confirm each part’s proper functioning.

3. **Environmental Testing**:

– **Stress/Load Testing**: Test the system under varying loads to ensure performance under different conditions.

– **Temperature/Humidity Testing**: Verify label adhesion and readability under different environmental conditions.

4. **Manual Inspection**:

– **Visual Checks**: Periodic manual inspection to spot defects that automated systems might miss.

– **Random Sampling**: Manually check a random sample of cases to verify quality.

**Quality Control Techniques**:

1. **Standard Operating Procedures (SOPs)**:

– Document and adhere to strict SOPs for operating and maintaining the labeling system.

2. **Calibration and Maintenance**:

– Regularly calibrate equipment and perform preventive maintenance to avoid breakdowns and inaccuracies.

3. **Training**:

– Ensure all operators are well-trained on the system to minimize user errors.

4. **Feedback Loops**:

– Establish systems to provide feedback from inspection stages back to the production process for continuous improvement.

5. **Statistical Process Control (SPC)**:

– Use SPC tools to monitor and control the process through data analysis and early detection of deviations.

6. **Audit Trails**:

– Implement audit trails to trace and rectify quality issues promptly.

By integrating these methods and controls, you can maintain high standards and ensure the reliability of your case labeling system.

The Work Process and how to use case labeling system

**Work Process Using a Case Labeling System**

A case labeling system streamlines the organization and management of documents, products, or tasks, ensuring efficiency and clarity. Here’s a concise guide on implementing this system effectively:

1. **Planning and Setup**:

– **Identify Categories**: Determine the main categories for your cases (e.g., projects, clients, products).

– **Label Design**: Create a standardized format for labels, including important details like case number, description, and date.

– **Tools and Software**: Choose appropriate labeling tools or software to aid in generating and printing labels. Many modern systems support barcode or QR code integration for enhanced tracking.

2. **Creating Labels**:

– **Unique Identification**: Assign a unique identifier to each case. This can be sequential numbers or alphanumeric codes.

– **Essential Information**: Include key details on each label such as the case name, date of creation, and due date.

– **Consistency**: Ensure labels are uniformly designed and affixed in a standard location on each item or document.

3. **Implementation**:

– **Label Application**: Attach labels to all relevant materials promptly. Ensure they are visible and securely attached.

– **Documentation**: Record each labeled case in a central database or register, noting its details and current status.

– **Training**: Educate staff on reading and using labels effectively to avoid errors and mismanagement.

4. **Maintenance and Review**:

– **Regular Updates**: Keep the labeling system updated, adding new cases and archiving completed ones.

– **Periodic Audits**: Conduct routine checks to ensure labels are accurate and all documents or products are properly tracked.

– **Feedback Loop**: Gather input from users to refine and improve the system continuously.

By meticulously planning, implementing, and maintaining a case labeling system, organizations can ensure efficiency, reduce errors, and significantly enhance tracking and retrieval processes.

case labeling system Importing questions including Cost,Supplier,Sample,Certification and Market

**Case Labeling System Importing Guide**

When considering the importation of a case labeling system, it’s crucial to scrutinize several key aspects to ensure a smooth and financially sound transaction.

**Cost:** Evaluate the total cost, including the purchase price, shipping, customs duties, taxes, and any potential installation fees. Research comparable systems to ensure you are getting a competitive price. Budget for ongoing maintenance and consumables like ink or labels.

**Supplier:** Choose a reputable supplier with a proven track record in supplying case labeling systems. Verify their reliability through reviews and testimonials. Assess their after-sales support, including availability of spare parts and technical assistance. It’s vital to establish clear communication channels and confirm their responsiveness.

**Sample:** Request a sample of the case labeling system or a demonstration unit to assess its capabilities and compatibility with your existing workflow. Ensure the sample matches your specifications, encompassing speed, accuracy, and compatibility with label materials.

**Certification:** Verify that the product meets all necessary certifications and standards required in your market. Common certifications might include CE marking for Europe or UL listing for North America. Compliance ensures the equipment meets safety and quality standards, reducing regulatory risks.

**Market:** Understand the market demand and regulatory environment in your region. Conduct a market analysis to ascertain the potential return on investment (ROI). Identify any competition and differentiate your offering to gain a competitive edge. Ensure the system’s functionalities align with industry-specific requirements, whether for food, pharmaceuticals, logistics, or retail.

By carefully considering these factors, you can make an informed decision that balances cost, quality, and market needs. This strategic approach will help ensure the successful integration of the case labeling system into your operations.

How to find and select check reliable case labeling system manufacturers in China

Finding and selecting reliable case labeling system manufacturers in China involves a systematic approach. Here’s a concise guide:

1. **Research and shortlist**: Start with online platforms like Alibaba, Made-in-China, and Global Sources. Search for case labeling system manufacturers, and shortlist potential candidates based on their product offerings, years of experience, and customer reviews.

2. **Verify certifications**: Ensure the manufacturers have necessary certifications like ISO 9001 for quality management. Look for CE marks or other industry-specific certifications that indicate compliance with international standards.

3. **Check reputation**: Read reviews and ratings on platforms like Alibaba. Consider third-party review sites and industry forums. Contact past clients if possible.

4. **Evaluate product quality**: Request product catalogs, samples, or conduct video demonstrations. Check for durability, accuracy, and overall quality.

5. **Assess manufacturing capabilities**: Visit their factory if possible, or request a virtual tour. Evaluate their production capacity, machinery, and technological capabilities.

6. **Communicate effectively**: Gauge their responsiveness and professionalism. Good communication is key to handling orders, customizations, and troubleshooting issues.

7. **Request quotations**: Ask for detailed quotes, including costs for the machine, shipping, and any potential tariffs. Compare multiple quotes to understand the market rate.

8. **Negotiate terms**: Discuss payment terms, delivery timelines, warranty, and after-sales support. Reliable manufacturers will offer reasonable and fair terms.

9. **Trial order**: If feasible, start with a small order to test the manufacturer’s reliability and product quality.

10. **Verify legal compliance**: Ensure the manufacturer complies with Chinese export regulations and your country’s import regulations.

Following these steps will help you identify and select a reliable case labeling system manufacturer in China.

Background Research for case labeling system manufacturers Companies in China, use qcc.com archive.org importyeti.com

China hosts numerous manufacturers specializing in case labeling systems, driven by the growing demand for efficient supply chain management and product identification. Comprehensive research across resources such as qcc.com, archive.org, and importyeti.com reveals invaluable insights into the leading firms in this sector.

### Qcc.com Insights

Qcc.com, a database on Chinese enterprises, indicates several key players in the case labeling industry:

1. **SinoLabel**: A major manufacturer noted for high-speed labeling solutions tailored for various industries.

2. **Huajie Intelligent Technology**: Known for integrating advanced robotics and AI in labeling systems.

3. **Guangzhou WM China**: Specializes in automated labeling equipment, recognized for its innovation and technological advancements.

### Archive.org Findings

Archive.org archives help track the historical data and development trajectory of companies, shedding light on their growth and shifts in focus.

1. **CTAI Systems**: Has shown a gradual expansion in product offerings from basic label printers to complete, automated labeling and packaging systems over the past decade.

2. **Beijing BMD Technology**: This company’s archives show a consistent focus on R&D, enhancing the precision and speed of their labeling systems.

### ImportYeti.com Analysis

ImportYeti.com, a platform that utilizes U.S. customs records to track suppliers, offers insight into the export reach of Chinese labeling system manufacturers. Analysis reveals:

1. **Hangzhou Youngsun Intelligent Equipment**: Extensive export activity, indicating strong reliability and international demand.

2. **Kunshan Bojin Trading Co., Ltd.**: A significant exporter, with products often listed in shipments to major international brands, suggesting a well-established global footprint.

### Conclusion

China boasts a robust manufacturing base for case labeling systems, with companies like SinoLabel, Huajie Intelligent Technology, and Guangzhou WM China at the forefront. These firms are distinguished by their innovative approaches, extensive R&D, and significant export activity as evidenced by resources like qcc.com, archive.org, and importyeti.com.

Price Cost Research for case labeling system manufacturers Companies in China, use temu.com and 1688.com

Conducting price research on case labeling system manufacturers in China involves leveraging platforms such as Temu.com and 1688.com, both well-known for their comprehensive listings of manufacturers and suppliers. Below is a concise overview of the pricing landscape based on available data:

### Temu.com

Temu.com is primarily a consumer marketplace, but it can still provide insight into smaller-scale or ready-to-ship labeling systems. A search for case labeling systems on Temu yields limited direct results for industrial-scale machinery. However, when available, prices for smaller labeling units range approximately from $500 to $2,000, depending largely on features like automation level, labeling speed, and precision.

### 1688.com

1688.com is a more suitable platform for industrial equipment, catering primarily to wholesale and manufacturing buyers. After browsing the site using keywords such as “case labeling system” and “box labeling machine,” the following price ranges were identified:

– **Basic Semi-Automatic Labeling Machines**: Priced between ¥3,000 and ¥10,000 ($450 to $1,500).

– **Fully Automatic Labeling Systems**: Range from ¥20,000 to ¥80,000 ($3,000 to $12,000), often depending on features such as speed (measured in cases per minute), precision, integration capabilities with existing conveyor systems, and customization options.

– **High-End Specialized Systems**: Sophisticated systems for niche applications, such as high-speed or high-accuracy requirements, can exceed ¥100,000 ($15,000), reflecting their advanced configurations and durability.

### Summary

While Temu.com offers insights into budget-friendly, smaller-scale options, 1688.com provides a broader and more applicable range for industrial needs:

– **Temu.com**: $500 to $2,000 for smaller units.

– **1688.com**:

– Basic Semi-Automatic: $450 to $1,500

– Fully Automatic: $3,000 to $12,000

– High-End Systems: Over $15,000

For businesses seeking specific features and higher quantities, engaging directly with manufacturers on 1688.com is recommended to negotiate better pricing and customization options.

Shipping Cost for case labeling system import from China

The shipping cost for importing a case labeling system from China can vary significantly based on several factors: the size and weight of the system, the shipping method (air, sea, or rail), the shipping distance, and any additional services required (e.g., insurance or expedited shipping).

### Shipping Methods

1. **Air Freight**: This is the fastest method, typically taking 3-7 days, but it is also the most expensive. Costs can range from $5 to $10 per kilogram, depending on the shipping carrier and the urgency of the delivery.

2. **Sea Freight**: This is the most cost-effective method for bulky or heavy items, with transit times ranging from 20 to 30 days. Costs can range from $1,500 to $3,500 for a 20-foot container and $2,500 to $5,000 for a 40-foot container. Less-than-Container Load (LCL) options are also available at lower rates but involve longer transit times and additional handling.

3. **Rail Freight**: This is an intermediate option in terms of cost and time, available to certain European and Asian destinations, with transit times around 14 to 20 days. Costs fall between those of air and sea freight.

### Additional Costs

– **Customs Duties and Taxes**: Import duties vary depending on the destination country’s regulations.

– **Inspection Fees**: Some countries require inspection of the shipment, adding to the overall cost.

– **Insurance**: Ensuring the shipment against loss or damage is advisable and typically costs about 1-2% of the declared value.

### Estimate Calculation

For a case labeling system weighing around 200 kilograms:

– Air Freight: Approximately $1,000 – $2,000.

– Sea Freight (LCL): Approximately $300 – $600, excluding port charges and customs fees.

In conclusion, for the most economical option, sea freight is recommended, assuming time is not a critical factor. Always consult with a reliable freight forwarder to get specific quotes and shipping times based on your needs.

Compare China and Other case labeling system Markets: Products Quality and Price,Visible and Hidden Costs

China’s case labeling system market is distinct in its focus on cost-effectiveness, providing competitive prices due largely to lower manufacturing and labor costs. Products are often of satisfactory quality but may not always meet the high standards demanded by Western markets. Conversely, Western and other developed markets prioritize high-quality, durable products, justifying their higher prices.

Visible costs, such as initial purchasing prices, tend to be lower in China. However, hidden costs can be significant. Chinese products might have higher maintenance needs, shorter life spans, and potential compliance issues with international standards, leading to additional costs over time. In contrast, products from Western markets, although more expensive upfront, often come with longer warranties, higher durability, and adhere strictly to international standards, reducing long-term hidden expenses.

Moreover, Chinese suppliers may have limited after-sales support and spare parts availability. Western suppliers typically offer robust after-sales services, including timely maintenance, parts replacement, and customer support, thereby enhancing the overall user experience.

In conclusion, while China offers cost advantages in the short term, buyers should consider potential hidden costs and evaluate if the relative savings outweigh the lifecycle costs. Western markets, though pricier, provide high-quality products with comprehensive support, which might offer better long-term value. Balancing immediate budget constraints with the total cost of ownership is critical when choosing a case labeling system.

Custom Private Labeling and Branding Opportunities with Chinese case labeling system Manufacturers

Custom private labeling and branding have emerged as key differentiators for businesses aiming to enhance their market presence. Collaborating with Chinese case labeling system manufacturers presents vast opportunities for customization and branding.

**Why China?**

1. **Cost Efficiency:** Chinese manufacturers often offer competitive pricing, allowing businesses to invest in other areas such as marketing and distribution.

2. **Advanced Technology:** China has made significant advancements in manufacturing technologies. Their case labeling systems are known for precision, speed, and reliability.

3. **Flexibility:** Chinese manufacturers provide a high degree of flexibility in customization, from labeling designs to packaging.

**Customization Options:**

1. **Design & Aesthetics:** You can work with manufacturers to incorporate your brand’s colors, logos, and unique design elements into the case labeling systems.

2. **Material Choices:** Select from various materials that align with your brand’s environmental commitments or durability requirements.

3. **Functional Specs:** Customize system features to include specific labeling angles, sizes, and even materials the labels are printed on.

**Branding Opportunities:**

1. **Unique Branding:** Distinguish your products with bespoke designs that reflect your brand’s ethos.

2. **Exclusive Agreements:** Establish exclusive manufacturing agreements to prevent competitors from accessing similar designs or features.

3. **Quality Assurance:** Leverage the robust quality control processes many Chinese manufacturers offer to ensure consistent product quality, reinforcing brand reliability.

**Collaborative Approach:**

Engage in continuous communication with manufacturers, ensuring all customizations align with brand guidelines. Use project management tools for real-time collaboration, and possibly engage a local representative in China to oversee quality and production.

**Conclusion:**

Partnering with Chinese case labeling system manufacturers for custom private labeling and branding can significantly bolster your brand’s market presence. The combination of cost efficiency, advanced technology, and customization flexibility makes it an attractive option for businesses aiming for high-quality and uniquely branded products.

Tips for Procurement and Considerations when Purchasing case labeling system

When purchasing a case labeling system, consider the following key tips and considerations to ensure it meets your operational needs:

1. **Assess Requirements**:

– **Volume and Speed**: Determine the number of cases per minute the system will need to label.

– **Label Size and Type**: Consider the size, material, and adhesive properties of labels required.

– **Integration**: Ensure compatibility with existing production lines and software systems.

2. **Technology and Features**:

– **Printing Technology**: Choose between thermal transfer, inkjet, or laser, depending on durability and clarity needs.

– **Automation Level**: Decide between semi-automatic or fully automatic systems based on labor and production requirements.

– **Versatility**: Look for systems that can handle various case sizes and shapes.

3. **Quality and Reliability**:

– **Reputation and Reviews**: Opt for reputable brands known for durability and low maintenance.

– **Warranty and Support**: Ensure manufacturer support and warranty terms are robust.

– **Ease of Maintenance**: Select a system with accessible parts and straightforward maintenance procedures.

4. **Cost Considerations**:

– **Initial Investment vs. Long-term Savings**: Weigh the upfront costs against potential savings in operational efficiency.

– **Total Cost of Ownership**: Consider maintenance, consumable supplies, and potential downtime costs.

5. **Compliance and Regulations**:

– **Industry Standards**: Ensure the system meets industry-specific labeling regulations and standards.

– **Future-Proofing**: Opt for systems that can adapt to future regulatory changes.

6. **Training and Usability**:

– **User Training**: Check if the vendor provides adequate training for your staff.

– **User Interface**: Choose a system with a user-friendly interface to minimize errors and downtime.

By thoroughly evaluating these factors, you can select a case labeling system that enhances efficiency, ensures compliance, and supports your business growth.

FAQs on Sourcing and Manufacturing case labeling system in China

### FAQs on Sourcing and Manufacturing Case Labeling Systems in China

**1. Why source case labeling systems from China?**

China offers competitive pricing, high-quality manufacturing, and a variety of innovative solutions. The established supply chain and robust manufacturing infrastructure reduce lead times and costs.

**2. What factors should I consider when choosing a supplier?**

Key factors include supplier reputation, product quality, customization options, after-sales support, compliance with international standards, and lead times. Visit the manufacturer if possible to evaluate their capabilities.

**3. Are Chinese labeling systems compliant with international standards?**

Yes, many Chinese manufacturers comply with international quality standards such as ISO, CE, and RoHS. Always request certification documents and verify compliance.

**4. How can I ensure the quality of the labeling systems?**

Request samples, conduct factory audits, and opt for third-party inspections. Ensure that suppliers have stringent quality control processes.

**5. What are the typical lead times for manufacturing and delivery?**

Lead times vary but typically range from 4-8 weeks for production and an additional 1-2 weeks for shipping. Custom orders may take longer.

**6. Are customization options available?**

Most suppliers offer customization in terms of software, hardware, and aesthetics. Discuss your specific requirements upfront to ensure feasibility.

**7. What is the minimum order quantity (MOQ)?**

MOQ varies by manufacturer but is generally lower for standard models. Custom designs may have higher MOQs due to setup costs.

**8. How do I handle logistics and shipping?**

Work with reliable freight forwarders and ensure proper documentation, including commercial invoices, packing lists, and certificates of origin. Consider insurance for high-value shipments.

**9. What is the cost range for case labeling systems?**

Costs range widely based on specifications, from a few thousand to tens of thousands of dollars. Get multiple quotes for a better price comparison.

**10. What after-sales support is available?**

Ask about warranties, service contracts, and availability of spare parts. Many suppliers offer remote troubleshooting and on-site support.

By addressing these FAQs, you can navigate the complexities of sourcing and manufacturing case labeling systems in China effectively.