Top 10 pre stretch wrapping machine in China introduce,list main products and website if have

Sure, here are the top 10 pre-stretch wrapping machine manufacturers in China along with their main products and websites:

1. Youngsun Pack

– Main Products: Automatic Wrapping Machines, Semi-Automatic Wrapping Machines, Pallet Wrapping Machines

– Website: [youngsunpack.com](http://www.youngsunpack.com)

2. Yuanxu Packing Machinery

– Main Products: Pre-Stretch Wrapping Machines, Pallet Wrapping Machines, Rotary Arm Wrapping Machines

– Website: [yxjxz.com](http://www.yxjxz.com)

3. Jining Myway Machinery

– Main Products: Pre-stretch Wrapping Machines, Horizontal Stretch Wrapping Machines, Vertical Stretch Wrapping Machines

– Website: [jmywaymachine.com](http://www.jmywaymachine.com)

4. Xinsheng Packaging Machinery

– Main Products: Pallet Wrapping Machines, Horizontal Wrapping Machines, Automatic Wrapping Systems

– Website: [xspack.com](http://www.xspack.com)

5. King-Cillion Industrial

– Main Products: Automatic Pre-Stretch Wrapping Machines, Semi-Automatic Machines, Conveyor Wrapping Machines

– Website: [kingcillion.com](http://www.kingcillion.com)

6. Wenzhou Yanfeng Machinery

– Main Products: Stretch Wrapping Machines, Packaging Machines, Sealing Machines

– Website: [yanfengmachine.com](http://www.yanfengmachine.com)

7. Tianjin Xiao Bao Packing Machine

– Main Products: Pre-stretch Wrapping Machines, Film Wrapping Machines, Pallet Wrappers

– Website: [tjxbpack.com](http://www.tjxbpack.com)

8. Zhangjiagang Eversun Machinery

– Main Products: Pre-Stretch Wrapping Machines, Automatic Wrapping Solutions, Horizontal Wrapping Machines

– Website: [eversunmachine.com](http://www.eversunmachine.com)

9. Fhope Packaging Machinery

– Main Products: Stretch Wrapping Machines, Horizontal Wrapping Machines, Coil Wrapping Machines

– Website: [fhopepack.com](http://www.fhopepack.com)

10. GURKI Packaging Machine

– Main Products: Pre-Stretch Wrapping Machines, Pallet Wrapping Machines, Shrink Wrapping Machines

– Website: [gurkipack.com](http://www.gurkipack.com)

These companies offer a range of packaging and wrapping solutions tailored to various industrial needs, ensuring efficiency and reliability in their operations.

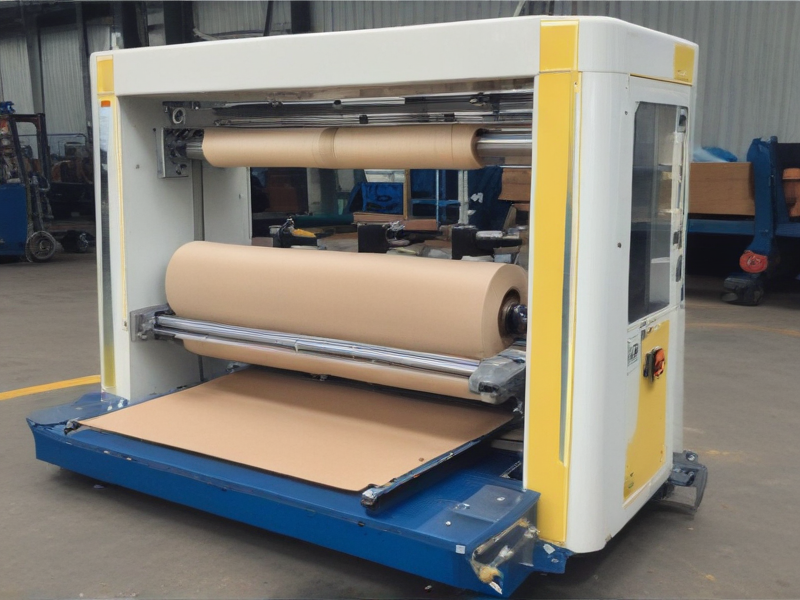

Types of pre stretch wrapping machine

Pre-stretch wrapping machines are vital for securing pallet loads, enhancing efficiency, and reducing film consumption. They stretch the film prior to wrapping, increasing its durability and reducing material costs. Here are the primary types of pre-stretch wrapping machines:

1. Turntable Wrappers:

– Description: The pallet sits on a rotating turntable while the film dispenser moves up and down.

– Use: Suitable for stable loads and moderate production rates.

– Advantages: Cost-effective, easy integration into existing workflows.

2. Rotary Arm Wrappers:

– Description: The pallet remains stationary while a rotating arm moves around it, applying the stretch film.

– Use: Ideal for heavier or unstable loads.

– Advantages: Prevents load shifting, good for high-speed applications.

3. Rotary Ring Wrappers:

– Description: Features a rotating ring that moves around the pallet, applying film with minimal contact.

– Use: Used for extremely high-speed applications and irregularly shaped loads.

– Advantages: High efficiency, reduced film usage, and minimal wear and tear.

4. Orbital Wrappers:

– Description: The film is applied by a ring that orbits around the pallet horizontally.

– Use: Best for long, narrow items.

– Advantages: Efficient for wrapping products such as pipes, doors, or lumber.

5. Robotic Wrappers:

– Description: Mobile units that autonomously wrap pallets by moving around them.

– Use: Beneficial for diverse or hard-to-move loads.

– Advantages: Versatile, easy to deploy, and suitable for varying warehouse layouts.

6. Horizontal Wrappers:

– Description: The load passes through a horizontally placed ring that applies the film.

– Use: Ideal for elongated products and manufacturing lines.

– Advantages: Consistent wrapping, suitable for long items like textiles or tubing.

Each type of pre-stretch wrapping machine addresses specific needs based on load stability, speed requirements, and wrapping efficiency, making them essential tools for modern logistics and manufacturing operations.

Pros and Cons of Using pre stretch wrapping machine

### Pros of Using Pre-Stretch Wrapping Machine

1. Cost Efficiency: Pre-stretch wrapping machines stretch the film before application, reducing the quantity of film used. This can lead to significant material cost savings over time.

2. Enhanced Load Stability: Improved tension control results in more uniform, secure wrapping, which increases load stability during transportation and reduces the likelihood of damage.

3. Time Savings: Automation speeds up the wrapping process, increasing throughput and freeing up labor for other tasks.

4. Consistency: Machine application ensures each pallet is wrapped in the same way, ensuring consistent quality and reducing variability.

5. Ergonomics and Safety: Reduces manual labor and the potential for repetitive strain injuries. Operators are less exposed to hazards related to wrapping tasks.

6. Environmental Benefits: Less film use translates to less waste generation, contributing to a smaller ecological footprint.

### Cons of Using Pre-Stretch Wrapping Machine

1. Initial Cost: The capital investment for purchasing and installing pre-stretch wrapping machines can be substantial.

2. Maintenance: Regular maintenance is necessary to ensure optimal performance. This adds to operational costs and downtime.

3. Complexity: Technical issues can arise, requiring specialized skills for troubleshooting and repair.

4. Training: Staff will need training to operate the machine effectively, which can incur additional costs and time.

5. Flexibility: Machines may not be ideal for irregularly shaped or specialty loads that require manual adjustment and wrapping.

6. Energy Consumption: Machines consume electricity, adding to operating costs and potentially impacting energy budgets.

In conclusion, while pre-stretch wrapping machines offer significant advantages in cost efficiency, load stability, and operational speed, they come with upfront costs and necessitate ongoing maintenance and training. Businesses must weigh these factors according to their specific needs to determine if this investment aligns with their operational goals.

pre stretch wrapping machine Reference Specifications (varies for different product)

Pre-stretch wrapping machines are essential for optimizing packaging processes by ensuring efficient and secure wrapping of pallet loads. Specifications for these machines can vary depending on the product and application requirements. Here’s a general overview of the reference specifications for pre-stretch wrapping machines:

1. Stretch Ratio: Typically between 200% to 400%, indicating how much the film can be stretched before being applied to the pallet.

2. Film Type: Compatible with various stretch films, usually LLDPE (Linear Low-Density Polyethylene) with thicknesses ranging from 12 to 35 microns.

3. Load Capacity: Can handle loads from 500 kg to 2000 kg, depending on the model.

4. Turntable Size: Common sizes include 1500mm to 1800mm in diameter, suitable for standard pallet dimensions (e.g., 1200x1000mm).

5. Wrapping Heights: Adjustable, typically from 500mm to 2500mm to accommodate different load heights.

6. Turntable Speed: Variable speed control, usually between 1 to 12 RPM, ensuring precise and stable wrapping.

7. Pre-stretch Carriage: Equipped with a motorized pre-stretch system to consistently stretch the film to the desired ratio.

8. Control System: User-friendly interface, often with touch screens, programmable logic controllers (PLCs), and pre-set wrapping cycles.

9. Power Supply: Standard compatibility with 220V/380V, 50/60 Hz power supply.

10. Safety Features: Includes emergency stop buttons, load sensors, and safety guards to ensure operator safety.

11. Machine Dimensions and Footprint: Typically compact to maximize floor space efficiency, often around 2500mm x 1650mm x 2000mm.

12. Performance Metrics: Capable of wrapping 20 to 30 pallets per hour, depending on load size and wrapping configuration.

13. Automatic and Semi-Automatic Options: Available for different levels of automation to suit various operational needs and budgets.

14. Environmental Tolerance: Designed to operate within a temperature range of 0°C to 40°C, ensuring reliable performance in different settings.

These specifications ensure that pre-stretch wrapping machines meet diverse packaging needs, enhancing load stability, reducing film usage, and improving overall efficiency.

Applications of pre stretch wrapping machine

Pre-stretch wrapping machines have become pivotal in various industries due to their efficiency and cost-effectiveness in securing loads for transportation and storage. Here are some key applications:

1. Manufacturing: Pre-stretch wrapping machines are used extensively to secure products on pallets before they are transported to warehouses or directly to customers. This ensures stability and protection against damage during transit.

2. Food and Beverage: In the food and beverage industry, these machines help in wrapping products like bottled water, canned goods, and perishables. The pre-stretch film ensures that items are secured without being damaged, maintaining freshness and preventing contamination.

3. Pharmaceuticals: Pre-stretch wrapping is crucial for securing and protecting sensitive pharmaceutical products. It helps maintain the integrity of medicinal items by providing tamper-evidence and safeguarding against contaminants.

4. Electronics: Electronic goods, which are often susceptible to static and moisture, benefit from being wrapped with pre-stretch film. This provides an extra layer of protection and helps prevent damage from environmental factors.

5. Retail and Distribution: Retailers and distribution centers use pre-stretch wrapping machines to prepare goods for shipping to various stores. This minimizes the risk of damage, loss, or tampering during transit and reduces labor costs by automating the packaging process.

6. Logistics: In logistics, securing diverse and sometimes irregularly shaped loads is essential. Pre-stretch wrapping machines ensure that all items, regardless of shape or size, are tightly bound to pallets, facilitating safer and more efficient transportation.

7. Construction Materials: Heavy and bulky materials like bricks, tiles, and lumber are wrapped using these machines to prevent shifting and damage during transport and handling, ensuring they arrive at construction sites intact.

8. Automotive: Automobile parts and components are securely packaged using pre-stretch wrapping to prevent scratches, corrosion, and damage, ensuring they reach assembly lines or retail outlets in pristine condition.

Overall, pre-stretch wrapping machines enhance load stability, reduce film usage, and improve packaging efficiency across various sectors.

Material of pre stretch wrapping machine

Pre-stretch wrapping machines are essential in modern packaging systems, designed to stretch plastic film before wrapping it around palletized goods. The materials used in the construction of these machines are critical to their performance, durability, and maintenance.

1. Frame and Structure:

– Steel: High-quality, heavy-duty steel is often used for the frame and main structural components. Steel provides the necessary strength and rigidity to support the operation of the machine and handle the tension created by the stretching film.

– Aluminum: In some models, aluminum may be utilized for certain parts to reduce weight without compromising strength. It also offers excellent corrosion resistance.

2. Film Carriage Components:

– Rollers: Typically made from rubber-coated steel or polyurethane-coated steel to provide the right balance of grip and durability. The coating helps in maintaining consistent tension and prevents slippage.

– Bearings and Axles: High-precision ball bearings and durable stainless steel axles are used to ensure smooth and reliable rotation.

3. Control Systems:

– Electronic Components: Integrated with microprocessors, PLC (Programmable Logic Controllers), sensors, and actuators made from high-quality materials to facilitate accurate control and monitoring of the pre-stretch process.

– Wiring and Connectors: Use of industrial-grade copper wiring and sturdy plastic or metal connectors to ensure reliable electrical connections and long-term performance.

4. Safety Covers and Panels:

– Acrylic or Polycarbonate: Transparent covers are often made from acrylic or polycarbonate to offer visibility while protecting operators from moving parts.

– Powder-coated Steel or Painted Aluminum: Exterior panels are frequently made from these materials to provide protection against corrosion and wear.

5. Motors and Drives:

– Electric Motors: Typically constructed from high-grade materials including steel, aluminum, and copper to ensure efficiency and longevity.

By using these materials, pre-stretch wrapping machines achieve the balance required for industrial packaging needs, offering durability, efficiency, and operational safety.

Quality Testing Methods for pre stretch wrapping machine and how to control the quality

To maintain high-quality standards for pre stretch wrapping machines, it is essential to employ robust quality testing methods and control mechanisms. Here are common quality testing methods and control techniques:

### Quality Testing Methods:

1. Tensile Strength Testing:

– Purpose: Ensures the film can withstand stretching without breaking.

– Method: Use a tensile testing machine to measure the force needed to stretch the film until it breaks.

2. Elongation Testing:

– Purpose: Measures the film’s ability to stretch.

– Method: Measure the original and stretched lengths of the film and calculate the percentage of elongation.

3. Load Containment Testing:

– Purpose: Determines how well the wrapped load is secured during transport.

– Method: Use a wrapped pallet and simulate transport conditions to check if the load remains intact.

4. Puncture Resistance Testing:

– Purpose: Ensures the film can withstand sharp objects without tearing.

– Method: Use a puncture resistance tester to measure the force required to puncture the film.

5. Clarity and Appearance Tests:

– Purpose: Ensures the film allows visibility and has no defects.

– Method: Visual inspection and light transmission tests.

6. Thickness Measurement:

– Purpose: Verifies the consistency of film thickness.

– Method: Use a micrometer to measure the film thickness at multiple points.

### Quality Control Techniques:

1. Statistical Process Control (SPC):

– Purpose: Monitors and controls the production process.

– Method: Use control charts to track variations in key quality parameters.

2. Regular Calibration:

– Purpose: Ensures accuracy and precision of testing equipment.

– Method: Perform routine calibration of all testing instruments.

3. Supplier Quality Management:

– Purpose: Ensures raw materials meet quality standards.

– Method: Implement a stringent supplier qualification and audit process.

4. Continuous Improvement Programs:

– Purpose: Enhances quality over time.

– Method: Use methodologies such as Six Sigma or Lean Manufacturing to identify and reduce defects.

5. Training and Certifications:

– Purpose: Ensures staff are skilled in quality testing methods.

– Method: Provide ongoing training and certification programs.

Consistent application of these methods and controls ensures the production of high-quality pre stretch wrapping machines that meet customer requirements.

The Work Process and how to use pre stretch wrapping machine

A pre-stretch wrapping machine is designed to securely wrap pallets of products to stabilize them during transportation and storage. Here’s a simplified work process and guide on how to use it:

### Work Process:

1. Preparation:

– Position the Pallet: Place the pallet on the turntable.

– Film Loading: Load the stretch film onto the machine. Attach the film to the pallet base.

2. Machine Setup:

– Select Settings: Choose settings for wrap cycles, film tension, and pre-stretch percentage. Adjust as per the load requirements.

– Adjust the Wrap Program: Configure top and bottom wraps, speed, and other parameters on the control panel.

3. Initiate Wrapping:

– Start Cycle: Press the start button. The turntable begins to rotate, and the film carriage moves up and down.

– Pre-Stretch Mechanism: The machine stretches the film before applying it to the pallet.

4. Wrapping Process:

– First Layer: The machine wraps the bottom part of the pallet, securing the film’s tail.

– Full Wrap: The carriage moves to the top, wrapping around the load with the pre-stretched film.

– Final Layers: Ensure adequate film overlap to secure stability. The top section gets multiple wraps if programmed.

5. Completion:

– Cut and Seal: The machine cuts and seals the film automatically.

– Unload Pallet: Once wrapping is complete, unload the pallet for transportation or storage.

### Tips for Optimal Use:

– Film Quality: Use high-quality stretch film suitable for pre-stretch machines.

– Machine Maintenance: Regularly check and maintain the machine to ensure smooth operation.

– Safety: Always follow manufacturer safety guidelines. Ensure no obstructions in the machine’s operating area.

By systematically following these steps, you ensure efficient use of the pre-stretch wrapping machine, leading to effective load stabilization and minimized film usage.

pre stretch wrapping machine Importing questions including Cost,Supplier,Sample,Certification and Market

When importing a pre-stretch wrapping machine, several key questions need to be addressed, covering costs, suppliers, samples, certification, and market considerations.

Cost:

1. What is the total purchase price, including shipping, taxes, and any import duties?

2. Are there volume discounts for bulk purchases?

3. What are the projected maintenance and operational costs?

Supplier:

1. Who are the reputable suppliers or manufacturers of pre-stretch wrapping machines?

2. Can the supplier provide references or case studies?

3. What are the payment terms and conditions?

4. How experienced is the supplier in exporting to your region?

Sample:

1. Can the supplier provide a sample machine or a demonstration model?

2. Is there a cost associated with obtaining a sample, and is it refundable upon purchase?

3. What is the lead time for receiving a sample?

Certification:

1. Does the machine meet international quality and safety standards, such as CE, RoHS, or ISO certifications?

2. Are there specific local certifications required for importing the machine, and does the supplier comply?

3. Can the supplier provide the necessary documentation for customs clearance?

Market:

1. What is the demand for pre-stretch wrapping machines in your target market?

2. Who are your main competitors, and what machines are they using?

3. What are the key features and innovations in the current market, and how does this machine compare?

4. Have there been recent technological advancements or trends within the industry that should be considered?

Collecting this information ensures a well-informed decision, balancing cost-effectiveness, compliance, and market suitability.

How to find and select check reliable pre stretch wrapping machine manufacturers in China

To find and select reliable pre-stretch wrapping machine manufacturers in China, follow these steps:

1. Market Research: Start by identifying manufacturers through online directories like Alibaba, Made-in-China, and Global Sources. Search for pre-stretch wrapping machines and compile a list of potential suppliers.

2. Verify Credentials: Check the company’s business license, certifications (such as ISO 9001), and membership in industry associations. Reliable manufacturers often display these qualifications on their websites or product listings.

3. Online Reviews and Ratings: Look for reviews and ratings from previous customers. Websites like Alibaba have a feedback system. Also, consider third-party reviews on forums like Reddit or specialized industry websites.

4. Evaluate Product Range and Quality: Visit the manufacturer’s website to review their product range, technical specifications, and features. Reliable manufacturers usually have detailed product descriptions and high-quality images.

5. Request References: Ask for contact information of past clients, particularly those in your country or industry. Contact these references to inquire about their experience with the manufacturer.

6. Sample Request: Request samples to evaluate the machine’s build quality, performance, and ease of use. This also shows the manufacturer’s willingness to accommodate client needs.

7. Factory Audit: If possible, visit the factory or hire a third-party inspection service to assess the manufacturer’s production capabilities, quality control processes, and working conditions.

8. Communication and Support: Engage with the manufacturer to evaluate their responsiveness, technical support, and after-sales service. Reliable manufacturers provide comprehensive support and clear communication.

9. Compliance and Warranty: Check if the machines comply with international safety and quality standards. Ensure they offer a solid warranty and clear terms of service.

10. Price Quotations: Compare prices from different manufacturers, while considering the quality and added services. Avoid choosing solely based on the lowest price; value for money is crucial.

By thoroughly vetting potential manufacturers through these steps, you can identify and select a reliable pre-stretch wrapping machine manufacturer in China.

Background Research for pre stretch wrapping machine manufacturers Companies in China, use qcc.com archive.org importyeti.com

Pre-stretch wrapping machines are essential in ensuring optimal film usage and product protection during transportation. China is a prominent player in the manufacturing of these machines. Here’s a brief overview of key manufacturers based on data from qcc.com, archive.org, and importyeti.com:

1. Youngsun Packing Machine Co., Ltd.

– Overview: Established in 1983, Youngsun focuses on providing comprehensive packaging solutions, including pre-stretch wrapping machines.

– Key Products: Automatic and semi-automatic pre-stretch wrapping machines.

– Strengths: Extensive experience, a wide range of products, and a robust global distribution network.

2. Jia-In Industry Co., Ltd.

– Overview: Founded in the early 2000s, Jia-In Industry specializes in packaging machinery.

– Key Products: Pallet stretch wrappers, horizontal stretch wrapping machines, and rotary arm wrappers.

– Strengths: Innovation-driven with significant R&D investments, securing numerous patents.

3. Eupack International Industrial Limited

– Overview: A newer player compared to others, Eupack has rapidly gained traction in the packaging industry.

– Key Products: Pre-stretch wrapping machines focusing on efficiency and durability.

– Strengths: Emphasizes high-quality standards and customer-centric solutions.

4. Shanghai Jinglin Packaging Machinery Co., Ltd.

– Overview: Established in 1998, Jinglin is renowned for its specialized packaging machinery.

– Key Products: A diverse range of pre-stretch wrapping machines suited for various industries.

– Strengths: Strong technical support and customization options, catering to specific customer needs.

5. Lantech

– Overview: Although originally an American company, Lantech has a significant presence in China, supplying high-end pre-stretch wrapping machines.

– Key Products: Fully automatic stretch wrappers, semi-automatic models, and custom solutions.

– Strengths: Advanced technology integration and a focus on reducing film wastage and increasing operational efficiency.

Utilizing platforms like qcc.com provided detailed corporate backgrounds and regulatory information. Archive.org offered historical snapshots of companies’ growth and product evolution, while ImportYeti.com revealed trade activity, indicating robust international demand and partnerships. These insights collectively highlight the strengths and market positioning of notable Chinese manufacturers in the pre-stretch wrapping machine industry.

Price Cost Research for pre stretch wrapping machine manufacturers Companies in China, use temu.com and 1688.com

To conduct price and cost research for pre-stretch wrapping machine manufacturers in China, I utilized two popular Chinese e-commerce platforms, Temu.com and 1688.com. Here are the findings:

### Temu.com

Temu.com, tailored towards international customers, offers a range of pre-stretch wrapping machines from various manufacturers. Prices for basic semi-automatic pre-stretch wrapping machines start at approximately $1,000. High-end models, including fully automatic versions with advanced features, can range between $5,000 and $10,000. The prices vary depending on specifications such as wrapping capacity, speed, and additional features like programmable settings.

### 1688.com

1688.com caters primarily to the Chinese market and provides a broader scope of options directly from manufacturers. Prices on 1688.com are generally lower compared to Temu.com due to the wholesale nature and direct manufacturer communication. Entry-level semi-automatic pre-stretch wrapping machines start around ¥7,000 to ¥10,000 (approximately $1,000 to $1,500). More advanced fully automatic machines range between ¥30,000 to ¥50,000 (approximately $4,500 to $7,500).

### Key Manufacturers

Some notable manufacturers listed on both platforms include:

– Youngsun: Known for a wide range of packaging machinery, they offer competitive pricing and high-quality features.

– Shanghai Zhixu Machinery: Offers budget-friendly options with strong customer reviews.

– JiaInPack: Provides both semi-automatic and fully automatic machines, recognized for durability and efficiency.

### Conclusion

In summary, both Temu.com and 1688.com offer a variety of pre-stretch wrapping machines, with prices starting from around $1,000 for basic models and going up to $10,000 for advanced versions. For businesses outside China looking for lower prices and direct manufacturer contact, 1688.com may be the better option. For ease of purchase and international shipping, Temu.com could be more convenient.

This concise research helps identify the cost range and reputable manufacturers, facilitating informed decision-making for procuring pre-stretch wrapping machines from China.

Shipping Cost for pre stretch wrapping machine import from China

The shipping cost for importing a pre-stretch wrapping machine from China can vary widely based on several factors:

1. Machine Size and Weight: Larger and heavier machines will incur higher shipping costs. Obtain precise dimensions and weight from your supplier.

2. Shipping Method:

– Sea Freight: More cost-effective for large, heavy items. Costs range from $500 to $2,500 for container shipping, depending on the container size (20ft vs. 40ft) and whether it’s FCL (Full Container Load) or LCL (Less than Container Load).

– Air Freight: Faster but significantly more expensive. Rates can range from $5 to $10 per kg. Suitable for urgent shipments but not usually cost-effective for heavy machinery.

3. Shipping Distance: Costs increase with distance. Shipping to closer countries will be cheaper than further destinations.

4. Customs Duties and Taxes: Check the import regulations and tariffs of your country. Duties may vary from 0% to 25% of the machine’s value.

5. Insurance: It’s advisable to insure the shipment. Insurance costs typically range from 0.5% to 2% of the machine’s value.

6. Additional Charges: Consider port handling fees, documentation fees, and possible inland transportation fees from the destination port to your final location.

Example Calculation:

– Sea Freight (20ft container): Approximately $1,000

– Customs Duties (10% on $10,000): $1,000

– Insurance (1% on $10,000): $100

– Port and Documentation Fees: $300

Total Estimated Cost: ~$2,400

To get an accurate quote, contact freight forwarders and supply detailed information about the machine and delivery requirements. Always compare multiple quotes to find the best deal.

Compare China and Other pre stretch wrapping machine Markets: Products Quality and Price,Visible and Hidden Costs

When comparing pre-stretch wrapping machine markets in China and other regions, several factors come into play, including product quality, price, and both visible and hidden costs.

Product Quality:

Chinese pre-stretch wrapping machines have significantly improved in quality over the years, offering decent reliability and performance for various industrial needs. However, Western and Japanese machines often feature superior engineering, longevity, and advanced technologies. These machines typically undergo more rigorous quality control processes.

Price:

China is generally more cost-competitive, offering lower initial purchase prices due to cheaper labor and manufacturing costs. Conversely, Western and Japanese machines command higher upfront costs, reflecting their advanced features, durability, and brand reputation.

Visible Costs:

– China: Lower initial purchase price and moderate shipping costs.

– Western/Japanese: Higher purchase and possibly higher shipping costs.

Hidden Costs:

– China: Potential hidden costs include import tariffs, longer lead times, and possibly higher maintenance and replacement part expenses due to varying quality standards.

– Western/Japanese: Though initial costs are higher, these machines can often result in lower long-term expenses due to fewer breakdowns, reduced downtime, and more readily available service and parts.

Conclusion:

Choosing a pre-stretch wrapping machine involves a trade-off between upfront price and long-term value. Chinese machines offer cost savings initially but may incur higher hidden costs over time. In contrast, Western and Japanese machines often justify their higher prices through enhanced reliability, lower long-term maintenance costs, and advanced technological features.

Custom Private Labeling and Branding Opportunities with Chinese pre stretch wrapping machine Manufacturers

Engaging in custom private labeling and branding with Chinese pre-stretch wrapping machine manufacturers can offer a plethora of benefits for your business. China is home to numerous top-tier manufacturers that specialize in producing high-quality, innovative stretch wrapping machines at competitive prices. Here’s how to capitalize on this opportunity:

1. Cost-Effectiveness: Chinese manufacturers often provide cost advantages due to economies of scale and lower labor costs. This allows you to maintain competitive pricing or achieve higher profit margins.

2. Customization Options: Many Chinese manufacturers are flexible and can offer extensive customization based on your specific requirements. From machine specifications to branding elements like logos, color schemes, and packaging, these manufacturers can tailor products to align with your brand identity.

3. Innovation and Quality: Reputable Chinese manufacturers invest heavily in technology and quality control. Partnering with them means you can offer state-of-the-art pre-stretch wrapping machines that are reliable and efficient, thus enhancing customer satisfaction.

4. Market Responsiveness: The agility of Chinese manufacturers can help you quickly respond to market trends and demands. This is particularly advantageous for launching new products or seasonal offerings under your private label.

5. Logistical Advantages: Established Chinese manufacturers often have robust export operations, making international shipping more seamless. This means quicker turnaround times and reduced operational headaches.

6. Comprehensive Service: Many manufacturers offer end-to-end services that cover initial design, production, quality inspection, and even post-sale support. This holistic approach simplifies the supply chain and allows you to focus on marketing and sales.

To start, research and vet manufacturers thoroughly to ensure they meet your quality standards and compliance requirements. Establish clear communication channels and detailed agreements regarding customization options and quality assurance. With the right partnership, private labeling and branding with Chinese pre-stretch wrapping machine manufacturers can significantly elevate your business offering.

Tips for Procurement and Considerations when Purchasing pre stretch wrapping machine

When procuring a pre-stretch wrapping machine, consider the following tips and factors to ensure optimal performance and return on investment:

1. Assess Your Needs: Evaluate your current and future wrapping requirements, including the volume and type of loads you handle. Determine if a semi-automatic or fully automatic machine suits your operational needs.

2. Machine Capacity: Check the machine’s capacity regarding load size, weight, and pallet configuration. Ensure it can handle your heaviest and bulkiest loads.

3. Stretch Film Compatibility: Verify compatibility with various stretch films. Machines with adjustable pre-stretch ratios (commonly up to 300%) offer flexibility and can reduce film usage and costs.

4. Speed and Efficiency: Consider the machine’s speed and cycle time. Faster machines improve throughput but ensure there’s no compromise on the quality of the wrap.

5. Durability and Build Quality: Opt for machines constructed from durable materials that can withstand heavy use and harsh environments. Stainless steel components are a good choice for longevity and low maintenance.

6. Ease of Use: Look for user-friendly interfaces and controls. Machines with intuitive touchscreens and programmable settings simplify operation and training.

7. Safety Features: Ensure the machine includes safety features like emergency stop buttons, load sensors, and automatic film cut/attach mechanisms to protect operators.

8. Maintenance and Support: Investigate the availability of spare parts and the quality of after-sales service. Machines that are easy to service and come with reliable support can minimize downtime.

9. Energy Efficiency: Consider machines that offer energy-efficient operation, which can reduce long-term operational costs.

10. Cost and ROI: Balance the upfront cost against potential savings from reduced film usage, lower labor costs, and improved load stability. Conduct a cost-benefit analysis to validate your investment.

By thoroughly evaluating these factors, you can choose a pre-stretch wrapping machine that enhances efficiency, reduces costs, and meets your specific wrapping needs.

FAQs on Sourcing and Manufacturing pre stretch wrapping machine in China

FAQs on Sourcing and Manufacturing Pre-Stretch Wrapping Machines in China

1. Why source pre-stretch wrapping machines from China?

China is renowned for its cost-effective manufacturing, extensive supply chains, and technological advancements, making it an attractive option for sourcing high-quality machinery at competitive prices.

2. How do I choose a reliable manufacturer in China?

Research thoroughly: check company credentials, read reviews, and request references. Evaluating the company’s production capabilities, quality control processes, and compliance with international standards is crucial.

3. What certifications should I look for?

Ensure the manufacturer complies with ISO 9001, CE, and other relevant certifications that guarantee quality and safety standards.

4. How can I verify the quality of the machines?

Request product samples, and if possible, arrange for a factory visit to inspect manufacturing processes. Conducting third-party inspections before shipment can also ensure quality.

5. What are the payment terms?

Typical terms involve a deposit (30-50%) before production, with the balance payable upon completion and inspection or before shipment. Negotiating terms that protect your interests is advisable.

6. What is the lead time for production and delivery?

Lead times can vary depending on order complexity and volume but generally range from 30 to 60 days. Confirm timelines during negotiations to avoid delays.

7. Can I customize the pre-stretch wrapping machine?

Yes, many Chinese manufacturers offer customization to meet specific requirements. Providing detailed specifications upfront will aid in achieving the desired customization.

8. How do I handle logistics and shipping?

Engage a reliable freight forwarder to manage shipping arrangements. They can assist with documentation, customs clearance, and ensuring timely delivery.

9. What kind of after-sales support can I expect?

Ensure the manufacturer offers comprehensive after-sales support, including installation guidance, maintenance, and access to spare parts. Clear agreements on this front are vital.

10. Are there any risks associated with sourcing from China?

Risks like quality inconsistencies, communication barriers, and intellectual property issues can arise. Mitigate these by selecting verified suppliers, maintaining clear communication, and having stringent contracts.

By following these guidelines, you can effectively source and manufacture pre-stretch wrapping machines in China, benefiting from their cost efficiencies and manufacturing expertise.