List Technical Parameters of “horizontal form fill seal machine”

A Horizontal Form Fill Seal (HFFS) machine is a flexible packaging system that forms, fills, and seals packages in a horizontal configuration. Here are its key technical parameters:

1. **Machine Speed**:

– Typically ranges from 30 to 120 packs per minute (PPM), depending on product and packaging materials.

2. **Film Width**:

– Compatibility with film widths ranging from 100mm to 600mm.

3. **Film Type**:

– Suitable for various film materials, including polyethylene (PE), polypropylene (PP), and laminated films.

4. **Bag Dimensions**:

– Bag width: Typically from 50mm to 300mm.

– Bag length: Can range between 50mm and 400mm.

5. **Sealing Type**:

– Both fin sealing and lap sealing options available, depending on film type and application.

6. **Temperature Control**:

– Precision temperature regulation for sealing jaws, usually within ±1°C.

7. **Power Requirements**:

– Generally operates on a power supply between 220V and 440V, with power consumption varying from 2kW to 5kW depending on machine size and speed.

8. **Air Consumption**:

– Requires compressed air typically between 6 to 8 bar, with a consumption rate around 300 to 600 liters per minute.

9. **Product Feeding System**:

– Options for continuous motion (belt) or intermittent motion (indexing) feeding systems.

10. **Control System**:

– Equipped with PLC (Programmable Logic Controller) for operation control.

– HMI (Human Machine Interface) touchscreen for user interaction and settings adjustment.

11. **Material Handling**:

– Ability to handle a range of product forms including solids, granules, powders, and liquids.

12. **Accuracy**:

– Filling accuracy depending on product type, typically ±1% to ±2%.

13. **Machine Dimensions**:

– Exact dimensions vary, but a typical machine may measure around 2500mm (length) x 1200mm (width) x 1800mm (height).

14. **Weight**:

– Generally weighs between 500 to 1500 kg depending on the model and added features.

These parameters ensure versatility and efficiency, making the HFFS machine suitable for various industries such as food & beverages, pharmaceuticals, and cosmetics.

List Product features of “horizontal form fill seal machine”

A horizontal form fill seal (HFFS) machine is a versatile packaging system used across various industries for efficiently packaging products. Here are some key features of the HFFS machine:

1. **Automation**: Fully automated processes for forming, filling, and sealing, reducing the need for manual intervention and increasing production efficiency.

2. **Versatility**: Capable of handling a wide range of product types including liquids, powders, granules, and solid items.

3. **High-Speed Operation**: Advanced technology allows for high-speed packaging, ensuring rapid product turnaround to meet high-demand requirements.

4. **Precision Filling**: Accurate dosing systems to ensure consistent fill levels, reducing product wastage and maintaining quality control.

5. **Customizable Packaging**: Flexibility to produce various pouch styles such as stand-up pouches, pillow bags, gusseted packages, and more, catering to different market needs.

6. **Material Compatibility**: Can handle different packaging materials including plastic films, laminates, foil, and paper, enhancing adaptability to various packaging specifications.

7. **Integrated Safety Features**: Equipped with safety guards, emergency stop buttons, and fail-safes to protect operators and equipment.

8. **User-Friendly Interface**: Touchscreen HMIs (Human-Machine Interfaces) for easy operation, monitoring, and control of the packaging process, which improves usability and reduces training time.

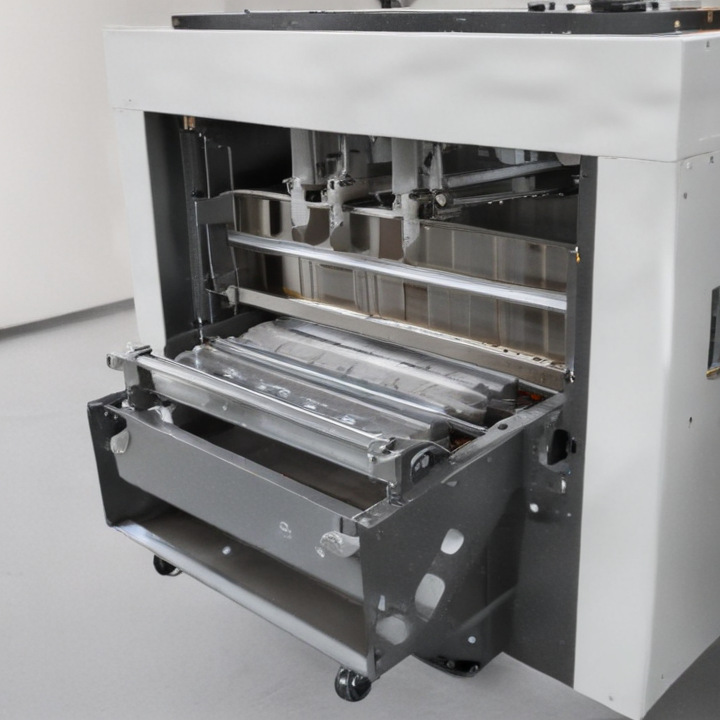

9. **Maintenance Accessibility**: Designed with easy access points for routine maintenance, troubleshooting, and cleaning, ensuring minimal downtime and prolonged machine life.

10. **Modular Design**: Scalable and modular setup options allow for easy upgrades and customization according to production needs.

11. **Reliable Sealing**: Advanced sealing technology ensuring airtight and leak-proof seals, contributing to longer shelf life for the packaged products.

12. **Energy Efficiency**: Designed to minimize energy consumption while maximizing output, aligning with sustainable production practices.

13. **Quality Control**: Features like vision systems and checkweighers to ensure products meet quality standards before leaving the production line.

14. **Cost-Effective Operation**: Optimizes material usage and reduces labor costs, making it a cost-effective solution for large and small-scale production lines.

These features make HFFS machines a valuable asset in the packaging industry, offering reliability, efficiency, and versatility.

List Application of “horizontal form fill seal machine”

Horizontal Form Fill Seal (HFFS) machines are versatile packaging machines widely used in various industries. Here are some key applications:

1. **Food Industry**:

– *Snacks and Confectionery*: Packaging of chips, candies, chocolate bars, and cookies.

– *Fresh Produce*: Wrapping of fruits and vegetables to prolong shelf life.

– *Dairy Products*: Sealing of cheese blocks, butter, and yogurt sachets.

– *Meat and Seafood*: Packaging of sausages, deli meats, and seafood products.

2. **Pharmaceutical Industry**:

– Packaging of tablets, capsules, and medical devices in sterile conditions.

– Blister packs for single-dose medications.

– Packaging of nutraceutical supplements.

3. **Cosmetics and Personal Care**:

– Sachets for creams, lotions, and shampoos.

– Sample packs for promotional purposes.

– Single-use packets for face masks and serums.

4. **Household Goods**:

– Wrapping of sponges, scouring pads, and cleaning wipes.

– Packaging of detergents and dishwasher pods.

– Sealing large rolls of trash bags or other consumables.

5. **Pet Food**:

– Packaging of kibble, treats, and specialized pet dietary products.

– Retort pouch packaging for moist and semi-moist dog and cat food.

6. **Industrial Goods**:

– Packaging of small hardware items like screws and bolts.

– Wrapping of industrial materials that need protection from external elements.

– Packaging of spare parts and electronics components.

7. **Beverages**:

– It’s less common, but some HFFS machines are adapted for single-use pouches of liquids like sauces, juices, and dairy drinks.

8. **Medical Devices**:

– Wrapping of disposable syringes, bandages, and swabs.

– Packaging of diagnostic test kits.

HFFS machines offer speed, efficiency, and versatility in packaging, making them ideal for high-volume production across various sectors. Their ability to handle different packaging materials and formats further enhances their applicability.

List Various Types of “horizontal form fill seal machine”

Horizontal Form Fill Seal (HFFS) machines are essential in the packaging industry for creating sealed packages by forming them from a flat, flexible material. These machines cater to a variety of packaging needs across different industries. Here are some types of HFFS machines:

1. **Flow Pack Machines**: These are ideal for high-speed packaging of individual items such as confectionery, bakery products, and fresh produce. The machine creates a continuous horizontal bag around the product.

2. **Pillow Pack Machines**: Used for packaging items in a pillow-shaped bag, these machines are common in snacks, pharmaceuticals, and small hardware items.

3. **Doypack Machines**: These form Doypack or stand-up pouches, suitable for liquids, powders, and granular products. They provide excellent shelf presence and stability.

4. **Vacuum Pack Machines**: These are designed for creating vacuum-sealed packs, primarily used in the food industry to extend shelf life by removing air from the package.

5. **Thermoforming Machines**: These machines use heat to form flexible or rigid plastic packaging around the product. They are commonly used for meat, cheese, and other perishable items.

6. **Blister Pack Machines**: These are used for products that need to be individually packaged in blister packs, such as medications, small electronics, and toys. The machine forms a cavity or pocket from a formable web and then fills and seals it.

7. **Sachet/Stick Pack Machines**: Suitable for single-use items like condiments, pharmaceuticals, and powders. These machines form, fill, and seal small packets that are easy to open and convenient for single servings.

8. **Cartoning Machines**: These machines form cartons from flat blanks, fill them with products, and then seal them. They are used for a variety of retail products such as cereals, health care products, and frozen foods.

Each type of HFFS machine varies based on its application, packaging material, and production requirements, ensuring versatility across different sectors.

Custom Manufacturing Options for horizontal form fill seal machine

Custom manufacturing options for horizontal form fill seal (HFFS) machines address various industry-specific needs, optimizing performance and efficiency. Key customization areas include:

1. **Material Compatibility**: Machines can be tailored to handle specific packaging materials like polyethylene, polypropylene, or biodegradable films, ensuring compatibility and product integrity.

2. **Size and Shape Flexibility**: Adjustable forming stations and sealing jaws allow the creation of various pouch sizes and shapes, from small sachets to large bags, catering to diverse product requirements.

3. **Filling Systems**: Customizable filling systems, including volumetric, auger, liquid, and multi-head weigher fillers, can be integrated to accommodate different product types like powders, granules, liquids, and semi-solids.

4. **Sealing Options**: Different sealing technologies—such as heat sealing, ultrasonic sealing, and zipper integration—offer manufacturers the ability to match the sealing method with the material and packaging needs.

5. **Printing and Labeling**: Integration of in-line printing, labeling, and coding systems allows for real-time application of branding, batch numbers, and expiry dates, enhancing traceability and compliance.

6. **Automation and Robotics**: Advanced automation features, including robotic arm integration for precise product handling and placement, increase operational efficiency and reduce labor costs.

7. **Sensors and Inspection Systems**: Custom sensor and inspection systems can be added to detect and remove defective packages, ensuring only quality products reach the consumer.

8. **User Interface and Control Systems**: Customizable HMIs (Human-Machine Interfaces) and control systems offer user-friendly operation, precise control, and monitoring capabilities, improving productivity and ease of use.

9. **Environmental Controls**: Custom enclosures or modifications like nitrogen flushing can be included to maintain product freshness and extend shelf life, particularly for food products.

These customizations ensure that HFFS machines are versatile and optimized to meet specific manufacturing needs, significantly enhancing their utility across various industries.

List Quality Control and The Manufacturing Process of “horizontal form fill seal machine”

The quality control and manufacturing process of a horizontal form-fill-seal (HFFS) machine involves several critical stages:

### Quality Control:

1. **Material Inspection**: Ensure that all raw materials and components comply with pre-defined quality standards through rigorous inspections.

2. **Precision Machining Checkpoints**: Evaluate parts during machining to ensure they meet precise specifications, using tools like calipers and micrometers.

3. **Assembly Verification**: Conduct checks at various stages of assembly to ensure components fit and function correctly.

4. **Electrical Testing**: Inspect electrical systems and wiring for functionality, safety, and compliance with standards.

5. **Operational Testing**: Run the machine through various scenarios to ensure it can consistently and accurately form, fill, and seal packages without errors.

6. **Final Inspection**: A thorough final examination to verify every part functions together seamlessly, ensuring the machine meets all operational and safety requirements.

### Manufacturing Process:

1. **Design and Prototyping**: Engineers create detailed blueprints and prototypes. Simulation software might be used to predict machine performance and address potential issues.

2. **Material Sourcing**: Quality raw materials such as metals for the frame, and components like sensors, motors, and electronics are procured from reliable suppliers.

3. **Fabrication**: Parts are manufactured using processes like CNC machining, laser cutting, and welding. Any deviations from the design specs are corrected immediately.

4. **Sub-Assembly Construction**: Machine parts like rollers, guides, and sealing units are assembled separately.

5. **Main Assembly**: Sub-assemblies are integrated into the main machine frame. Precision alignment ensures proper functioning.

6. **Electronics Integration**: Installation of electrical components, sensors, and control systems, followed by initial testing for functionality.

7. **Calibration and Testing**: Comprehensive testing and calibration to ensure the machine operates precisely in forming, filling, and sealing.

8. **Fine-Tuning**: Minor adjustments are made based on testing results to optimize performance.

9. **Quality Assurance**: Final inspections and certifications are conducted, ensuring the machine complies with regulatory standards.

10. **Packaging and Shipping**: The machine is securely packaged and shipped to the customer, ensuring it arrives safely and ready for installation.

These steps ensure that HFFS machines are reliable, efficient, and meet the stringent demands of modern packaging applications.

How to use “horizontal form fill seal machine”

A horizontal form fill seal (HFFS) machine is essential in packaging for creating sealed pouches from a flat roll of film. Here’s a step-by-step guide on how to use it:

1. **Loading the Film Roll:**

– Mount the roll of packaging film onto the unwind reel.

– Ensure the film is correctly aligned and tensioned to avoid misfeeds during operation.

2. **Setting Up the Machine:**

– Program the control panel with specific parameters: pouch dimensions, sealing temperature, and filling volume.

– Adjust the forming tools to match the film width and pouch size.

3. **Film Movement:**

– Engage the machine to pull the film horizontally through the system.

– It will pass through the forming collar, shaping it into a tube.

4. **Sealing the Pouch:**

– The machine will heat-seal the film edges to form the bottom and sides of the pouch.

– Ensure the sealing units are at the correct temperature for the film material to create a durable seal.

5. **Filling the Pouch:**

– The product (solid, liquid, powder) is then automatically dispensed into the formed pouches.

– Calibrate the filling system to ensure accurate product volume in each pouch.

6. **Final Sealing and Cutting:**

– The top of the pouch is sealed once the product is filled.

– The machine then cuts the sealed pouches from the continuous film.

7. **Collection and Inspection:**

– The finished pouches are collected, ready for inspection and packaging.

– Regularly check the pouches for consistent sealing and accurate filling.

**Tips for Efficient Operation:**

– Regularly maintain the machine to prevent downtime.

– Use high-quality film suited for the product to ensure reliable sealing.

– Monitor the output for any discrepancies and adjust settings as needed.

By following these steps, you can effectively use an HFFS machine for efficient and consistent packaging.

List Properties and Terms of “horizontal form fill seal machine”

A Horizontal Form Fill Seal (HFFS) machine is a versatile packaging equipment used extensively in various industries for creating sealed packages from rollstock material. Below is a list of properties and terms associated with HFFS machines:

### Properties:

1. **Automation Level**: Often highly automated, minimizing human intervention.

2. **Operation Speed**: Capable of high-speed production, essential for large-scale manufacturing.

3. **Versatility**: Suitable for packaging both solid and liquid products.

4. **Film Type**: Works with various packaging films like plastic, foil, and paper-laminates.

5. **Sealing Methods**: Employs heat sealing, ultrasonic sealing, or adhesive sealing.

6. **Product Handling**: Includes feeding, filling, and sealing in a continuous or intermittent motion.

7. **Customizability**: Tailorable to different package shapes and sizes.

8. **Accuracy**: Features accurate product filling mechanisms to avoid product wastage.

9. **Durability**: Built from robust materials to endure the packaging environment.

10. **Hygiene**: Designed to meet sanitary standards for food and pharmaceutical packaging.

### Terms:

1. **Forming**: The process of shaping the packaging material into the desired pouch or container.

2. **Filling**: The step where the product is introduced into the formed package.

3. **Sealing**: Ensuring the package is airtight and secure by bonding the material edges.

4. **Dosing System**: Equipment for accurate measurement and dispensing of product quantities.

5. **Rollstock**: The continuous roll of film material used for forming packages.

6. **Gusseted Pouch**: A type of package with folds on the sides or bottom to allow expansion.

7. **Perforation**: Lines of small holes made in the film to facilitate easy tearing.

8. **Thermoforming**: Using heat to mold the film into a specific shape.

9. **Rotary and Linear Machines**: Refers to the configuration of motion in the filling and sealing process.

10. **Maintenance**: Regular upkeep to ensure longevity and efficiency of the machine.

In summary, HFFS machines represent advanced packaging solutions, favoring efficiency, flexibility, and accuracy, crucial for various industrial applications.

List The Evolution history of “horizontal form fill seal machine”

The evolution of the horizontal form fill seal (HFFS) machine reflects advancements in packaging technology over the past century. Here’s a brief history:

**Early 20th Century:**

– **1920s-1930s:** Emergence of basic sealing machines, primarily for food products. These were manually operated and simple in design.

– **1940s:** Post-World War II: Increased demand for packaged goods led to mechanized sealing machines. Basic automated processes were introduced.

**Mid-20th Century:**

– **1950s:** Introduction of more sophisticated mechanical HFFS machines that could automatically form, fill, and seal bags or pouches from a roll of film, driven by increased consumerism.

– **1960s:** Enhanced reliability with the introduction of electronic controls and better materials.

**Late 20th Century:**

– **1970s:** Development of servo motor technology enhanced precision and speed. The machines became more versatile, capable of handling different types of packaging materials.

– **1980s:** Incorporation of programmable logic controllers (PLCs) allowed for increased automation and flexibility. Machines could now handle more complex packaging processes.

– **1990s:** Computerization further improved efficiency and ease of use. Systems became more user-friendly with touchscreens and advanced diagnostics.

**21st Century:**

– **2000s:** Digital technology and internet connectivity enabled remote monitoring and control. Machine designs became more hygienic and adaptable to various product types.

– **2010s:** Focus on sustainability led to machines that could handle biodegradable and recyclable films. Improved software allowed for better integration with production lines.

– **2020s:** Advanced sensors and AI began to be integrated for improved accuracy and predictive maintenance. Machines became even more energy-efficient and customizable.

Throughout its evolution, the HFFS machine has transitioned from simple, manually-operated devices to sophisticated, automated systems driven by technological advancements, reflecting broader trends in industrial automation and consumer demands.

How to Select a Reliable horizontal form fill seal machine

Choosing a reliable horizontal form fill seal (HFFS) machine is crucial for optimizing your packaging operations. Follow these guidelines to make an informed decision:

1. **Define Your Requirements**:

– **Product Type**: Ensure the machine can handle the physical properties of your product—whether it’s solid, liquid, granules, or powder.

– **Packaging Material**: Match the machine with your desired packaging material such as plastic, aluminum, or paper.

2. **Performance and Speed**:

– **Output Rate**: Verify the machine’s speed aligns with your production needs. Machines vary in speed, typically ranging from 30 to 300 packs per minute.

– **Accuracy**: Check for high precision in sealing and filling to minimize waste and ensure consistent product quality.

3. **Quality and Durability**:

– **Build Material**: Opt for machines made with high-quality materials like stainless steel for longevity and durability, especially in food or pharmaceutical applications.

– **Brand Reputation**: Research brands known for reliability and excellent customer support. Read reviews, case studies, and seek industry recommendations.

4. **Ease of Use and Maintenance**:

– **User Interface**: Look for easy-to-use controls and automation features like touchscreens, programmable settings, and error diagnostics.

– **Maintenance**: Ensure ease of access for cleaning and maintenance. Spare parts availability is crucial.

5. **Flexibility and Compatibility**:

– **Adaptability**: Choose a machine that offers flexibility in terms of packaging sizes, shapes, and any future scaling needs.

– **Integration**: Ensure compatibility with existing equipment in your production line for seamless integration.

6. **Cost and Value**:

– **Initial Cost vs. Long-term ROI**: Balance the upfront cost with expected long-term benefits, such as reduced labor costs and increased efficiency.

– **Energy Efficiency**: Consider energy-efficient machines to lower operational costs.

7. **Compliance and Certifications**:

– Ensure the machine complies with industry-specific regulations and standards like FDA, CE, or ISO certifications for safety and quality assurance.

By systematically evaluating these factors, you can select a reliable HFFS machine that meets your operational needs and long-term goals.

List “horizontal form fill seal machine” FAQ

### Horizontal Form Fill Seal Machine FAQs

1. **What is a Horizontal Form Fill Seal (HFFS) Machine?**

– A Horizontal Form Fill Seal machine is a type of packaging equipment that forms a pouch from a flat roll of film, fills it with the product, and seals it in a horizontal operation.

2. **What materials can HFFS machines use for packaging?**

– HFFS machines can handle a variety of materials including laminated films, polyethylene, foil, and paper-based films.

3. **What types of products can be packaged using an HFFS machine?**

– These machines are versatile and can package both solid and liquid products like snacks, powders, sauces, and pharmaceuticals.

4. **What speeds can be achieved with an HFFS machine?**

– Speeds vary by model but can range from 20 to over 200 packages per minute, depending on the product and packaging requirements.

5. **Are HFFS machines suitable for food packaging?**

– Yes, HFFS machines are often used in the food industry due to their capability to maintain product freshness and comply with sanitary standards.

6. **How can I ensure the machine is easy to clean and maintain?**

– Look for HFFS machines with easy-to-disassemble parts, stainless steel construction, and hygienic design features that facilitate cleaning and maintenance.

7. **What are the benefits of using an HFFS machine?**

– Benefits include high efficiency, versatility, minimal packaging waste, and the ability to produce high-quality, hermetically sealed packages.

8. **Can HFFS machines integrate with other equipment?**

– Yes, HFFS machines can be integrated with upstream and downstream equipment like feeders, printers, and secondary packaging systems.

9. **What should I consider when choosing an HFFS machine?**

– Consider the type of products, packaging materials, required speed, machine versatility, ease of maintenance, and your budget.

10. **Do HFFS machines support different pouch styles?**

– Yes, these machines can produce various pouch styles including pillow, gusseted, stand-up, and shaped pouches.

11. **Is customization available for HFFS machines?**

– Many manufacturers offer customization options to tailor the machine to specific packaging needs and production environments.

12. **What is the approximate cost of an HFFS machine?**

– Costs can vary widely, typically ranging from $50,000 to over $200,000 depending on the machine’s features and capabilities.

Top 10 FAQ with answer about horizontal form fill seal machine for Buyer Sourcing from China

Sure! Here’s a condensed FAQ about Horizontal Form Fill Seal (HFFS) machines for buyers sourcing from China:

1. **What is a Horizontal Form Fill Seal (HFFS) Machine?**

An HFFS machine automates packaging by forming, filling, and sealing products in a horizontal setup. It’s ideal for products like snacks, medical supplies, and consumer goods.

2. **Why Source an HFFS Machine from China?**

China offers competitive pricing, a broad range of manufacturers, and increasingly high-quality machines due to advancements in technology and manufacturing processes.

3. **What Should I Consider When Choosing a Supplier?**

Look for certifications (ISO, CE), customer reviews, technical support availability, after-sales service, and the supplier’s experience in exporting machinery.

4. **What Materials Can HFFS Machines Handle?**

These machines can handle a variety of packaging materials, such as plastic films, aluminum foil, and paper laminates, suitable for different products and industries.

5. **What Are Customization Options Available?**

Many Chinese suppliers offer machines tailored to specific requirements, such as custom mold sizes, filling systems (liquid, powder, granules), and special sealing options.

6. **What is the Lead Time for Delivery?**

Typically, the lead time ranges from four to eight weeks, depending on customization and production schedules. Confirm specifics with the supplier to manage your timeline expectations.

7. **How Do I Ensure Quality and Reliability?**

Request a video of the machine in operation, inquire about testing processes, check for warranty terms, and consider third-party inspections before shipment.

8. **What Are the Shipping and Import Regulations?**

Familiarize yourself with shipping terms like FOB or CIF, and ensure compliance with import regulations, including customs duties and required documentation in your country.

9. **What is the Cost Range?**

The cost of an HFFS machine can range from $10,000 to over $100,000 based on complexity, features, and customization. Always compare quotes from multiple suppliers.

10. **How Do I Handle Installation and Training?**

Many suppliers offer onsite installation and training services or provide comprehensive manuals and online support to ensure proper setup and operation.

These FAQs should offer a solid foundation for understanding and sourcing HFFS machines from China.