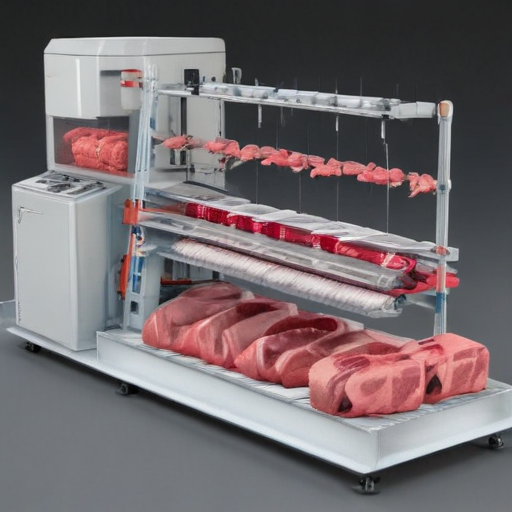

List Technical Parameters of “meat and poultry packaging machines”

When evaluating meat and poultry packaging machines, several technical parameters are crucial for ensuring high performance, efficiency, and compliance with safety standards. Here’s a concise list of essential parameters:

1. Machine Type: Including vacuum packaging machines, modified atmosphere packaging (MAP) machines, skin packaging machines, and flow wrap machines.

2. Material Compatibility: Ability to handle various packaging materials (e.g., polyethylene, polyamide, polypropylene, barrier films).

3. Throughput Rate: Measured in units per minute, influencing overall productivity.

4. Seal Integrity: Ensures airtight and hygienic seals, including temperature and pressure settings for sealing bars.

5. Vacuum Capacity: Measured in millibars or microns, critical for vacuum packaging machines to remove air effectively.

6. Gas Flushing Options: For MAP machines, the capability to inject and control gas mixtures like nitrogen and carbon dioxide.

7. Automation Level: Degree of automation, including semi-automatic to fully automatic systems.

8. Operational Speed: Speed settings for various processes (cutting, sealing, wrapping).

9. Load Capacity: Maximum weight and size of the product that the machine can handle.

10. Sanitation Features: Easy-to-clean designs, stainless-steel construction, and compliance with food safety standards (e.g., HACCP, USDA).

11. Control System: User interface, programmable logic controllers (PLC), and touchscreen control panels.

12. Energy Consumption: Efficiency ratings and power requirements.

13. Cutting Mechanism: Type of cutter (rotary, die-cutting), precision, and suitability for different products.

14. Temperature Control: Precision in maintaining specific packaging temperatures.

15. Footprint and Size: Dimensions of the machine, suited for the operational space available.

16. Maintenance Requirements: Ease of maintenance, availability of spare parts, and service intervals.

17. Safety Features: Emergency stops, safety guards, and compliance with regulatory safety standards.

18. Customization Options: Ability to tailor machine functions and options to specific packaging needs.

These parameters are pivotal for selecting and assessing the right packaging machine tailored to meat and poultry products, ensuring optimal performance and compliance with industry standards.

List Product features of “meat and poultry packaging machines”

Certainly! Here are the key features of meat and poultry packaging machines:

1. Hygienic Design: These machines are designed with stainless steel surfaces and smooth, easily cleanable areas to meet stringent food safety standards.

2. Automated Operation: Advanced automation reduces manual handling, ensuring higher efficiency and consistent packaging quality.

3. Vacuum Sealing: Many machines offer vacuum sealing to extend the shelf life of meat and poultry by removing air from the package.

4. Flexibility: Configurable options to handle various types of packaging materials such as films, vacuum bags, trays, and shrink bags.

5. High Speed: Capable of high throughput to meet industrial-scale production demands without compromising quality.

6. Precision: Accurate portion control and consistent weight measurement minimize waste and ensure uniformity.

7. Integration with Labeling: Equipped with labeling systems for branding, nutritional information, and batch coding.

8. Temperature Control: Integrated cooling mechanisms help maintain optimal temperatures during the packaging process to preserve product quality.

9. Safety Features: Include interlocked access doors, emergency stop buttons, and safety shields to protect operators.

10. Robust Construction: Built with durable materials to withstand the rigorous demands of meat and poultry operations.

11. User-Friendly Interface: Touchscreen controls and programmable settings facilitate ease of use and quick adjustments.

12. Customizable: Options for tailored designs and add-ons to fit specific production requirements.

13. Reduced Downtime: Easy maintenance and quick-change parts reduce downtime, keeping production lines running smoothly.

14. Eco-Friendly Options: Machines designed to minimize material waste and energy consumption.

15. Compliance: Adherence to industry regulations and standards like USDA and FDA.

This combination of features makes meat and poultry packaging machines indispensable in ensuring hygienic, efficient, and high-quality packaging processes for the food industry.

List Application of “meat and poultry packaging machines”

Meat and poultry packaging machines are specialized equipment designed to streamline the packaging process of meat and poultry products, ensuring they are preserved, safe, and appealing to consumers. Here are several key applications:

1. Vacuum Packaging:

– Extended Shelf Life: Vacuum packaging removes air before sealing, which significantly extends the shelf life of meat and poultry by reducing the growth of aerobic bacteria and fungi.

– Preservation of Quality: Maintains flavor, texture, and nutritional value by minimizing exposure to oxygen and preventing freezer burn.

2. Modified Atmosphere Packaging (MAP):

– Enhanced Freshness: Uses specific gas mixtures inside the packaging to prolong freshness, appearance, and safety, ideal for retail distribution.

– Customization: Different gas combinations can be tailored for specific types of meat and poultry to optimize preservation.

3. Thermoforming:

– Custom Fit Packaging: Automatically forms custom-sized packages from a roll of plastic film, providing a secure, tamper-evident seal.

– Bulk Packaging: Efficient for high-volume operations, such as commercial processors and wholesalers.

4. Tray Sealing:

– Ready-to-Cook Meals: Commonly used for pre-portioned, ready-to-cook products, combining convenience with airtight sealing to maintain quality.

– Aesthetic Packaging: Offers a clear view of the product, enhancing shelf appeal and consumer confidence.

5. Skin Packaging:

– Product Presentation: Encases the product tightly with a clear film, effectively showcasing the meat or poultry while maintaining freshness.

– Enhanced Protection: Provides superior protection against contaminants and mechanical damage during transport.

6. Flow Wrapping:

– High-Speed Packaging: Ideal for automated, high-speed environments, wrapping meat and poultry in a continuous film.

– Portion Control: Particularly useful for sliced deli meats, offering uniformity in portion sizes and ease of handling.

7. Chub Packaging:

– Efficient Bulk Packaging: Cylindrical packaging for bulk ground meats, providing efficient storage and transportation.

– Reduced Waste: Minimizes material usage compared to traditional packaging methods.

8. Shrink Wrapping:

– Product Stability: Ensures a tight fit around irregularly shaped products, minimizing movement and damage during handling and transport.

– Enhanced Aesthetics: Improves visual appeal by presenting a clean, polished look.

These applications highlight the versatility and critical role of meat and poultry packaging machines in the food industry, aimed at maximizing product longevity, safety, and consumer satisfaction.

List Various Types of “meat and poultry packaging machines”

Sure, here are various types of meat and poultry packaging machines:

1. Vacuum Packaging Machines: These remove air from the package before sealing, significantly extending the shelf life of meat and poultry by reducing oxidative spoilage and inhibiting the growth of aerobic microorganisms.

2. Thermoforming Machines: Thermoformers create custom-shaped packages by heating and forming plastic sheets. They are often used for creating vacuum or modified atmosphere packages for meat products.

3. Modified Atmosphere Packaging (MAP) Machines: These machines replace the air inside the package with a specific gas mixture (typically carbon dioxide, nitrogen, and oxygen) to prolong freshness and enhance shelf life.

4. Tray Sealing Machines: These seal pre-formed trays, often with a film, to maintain product integrity. They can also be integrated with MAP technology for added preservation benefits.

5. Flow Wrapping Machines: These machines wrap meat and poultry in plastic film, creating a tight, sealed package that ensures freshness and hygiene.

6. Form-Fill-Seal (FFS) Machines: These machines form the packaging material, fill it with the product, and then seal it. They are highly automated and used for high-speed packaging operations.

7. Shrink Wrap Machines: Utilizing heat, these machines shrink film tightly around the product, offering a tamper-evident seal and often enhancing the visual appeal of meat products.

8. Portioning and Slicing Machines: While not directly packaging machines, these machines portion and slice meat and poultry to prepare them for subsequent packaging, ensuring consistent product sizes and weights.

9. Skin Packaging Machines: These create a vacuum-sealed package without necessarily enclosing the entire product, often used for displaying fresh meat on trays.

Each type of machine caters to different packaging requirements, ensuring that meat and poultry products remain fresh, appealing, and safe for consumption.

Custom Manufacturing Options for meat and poultry packaging machines

Custom manufacturing options for meat and poultry packaging machines cater to the specific needs of various businesses, ensuring efficiency, compliance, and adaptability. These options generally encompass several key areas:

1. Material Compatibility: Machines can be customized to handle different types of packaging materials such as vacuum-sealed bags, modified atmosphere packaging (MAP), and shrink wraps. This flexibility ensures that the packaging preserves product freshness and extends shelf life.

2. Machine Dimensions: Custom dimensions are crucial for facilities with space constraints or unique layout requirements. Tailoring the size and footprint of the machine allows for optimal space utilization.

3. Speed and Capacity: Customization in speed and capacity ensures that the packaging lines meet the specific production goals. Whether a business needs high-speed lines for mass production or slower, controlled packaging for boutique products, machines can be adapted accordingly.

4. Automation Levels: Depending on the level of desired automation, machines can be equipped with varying degrees of technology. Options range from semi-automated systems to fully automated robotic solutions, enhancing precision and reducing labor costs.

5. Sanitation and Compliance: Custom features to meet hygiene standards are critical. Machines can be designed with easy-to-clean surfaces, stainless steel construction, and features that comply with FDA, USDA, and other regulatory bodies.

6. Integration Capabilities: Custom packaging machines should be able to integrate seamlessly with existing production lines and ERP systems. This includes compatibility with scanners, labelers, and weighers for a holistic packaging solution.

7. Specialized Functions: Certain products may require special handling, such as portion control, bone detection, or customized labeling. Machines can be adapted to incorporate these specialized functions.

Custom manufacturing of meat and poultry packaging machines brings adaptability, efficiency, and compliance to production processes, helping businesses meet their unique packaging needs while maintaining high standards of quality and safety.

List Quality Control and The Manufacturing Process of “meat and poultry packaging machines”

Quality Control in Meat and Poultry Packaging Machines:

1. Design Validation:

– Rigorous testing of initial prototypes.

– Compliance with industry standards and regulations (e.g., USDA and FDA).

2. Material Inspection:

– Inspection of raw materials for durability and safety.

– Use of food-grade materials to ensure compliance.

3. Component Testing:

– Evaluation of electronic and mechanical components.

– Stress and fatigue testing of moving parts.

4. Assembly Verification:

– Implementation of quality checkpoints during assembly.

– Use of precise alignment tools and jigs.

5. Operational Testing:

– Functionality tests within different operational conditions.

– Simulation of actual working environments (temperature, humidity, etc.).

6. Sanitation Protocols:

– Assurance of easy cleaning and maintenance design.

– Testing for compliance with hygiene standards.

7. Final Inspection:

– Comprehensive review of the final product.

– Verification of labeling and documentation.

Manufacturing Process of Meat and Poultry Packaging Machines:

1. Design and Engineering:

– Conceptualization of machine design.

– Use of CAD software for precise planning.

– Creation of detailed blueprints and specifications.

2. Material Procurement:

– Sourcing high-quality materials and components.

– Ensuring all materials meet industry standards for food safety.

3. Fabrication:

– Cutting, welding, and shaping metal parts.

– Machining components to exact specifications.

– Surface treatment for corrosion resistance.

4. Assembly:

– Assembling parts and sub-modules.

– Integration of electronic control systems.

– Calibration of sensors and actuators.

5. Testing:

– Initial individual component testing.

– System integration testing for overall functionality.

– Simulated operational testing to mimic real-world usage.

6. Finishing:

– Polishing and cleaning of external surfaces.

– Application of protective coatings if necessary.

7. Packaging and Shipping:

– Ensuring the machine is safely packaged.

– Documentation and preparation for delivery.

This concise approach emphasizes the integration of thorough quality control steps at each phase of the manufacturing process, ensuring the production of reliable and safe meat and poultry packaging machines.

How to use “meat and poultry packaging machines”

Using meat and poultry packaging machines involves several steps to ensure proper and hygienic packaging. Here’s a simplified guide:

1. Preparation:

– Ensure the machine is clean and sanitized.

– Gather all required materials: film, trays, labels, and sealing elements.

2. Setup:

– Load the packaging film or trays into the machine.

– Adjust settings according to the type of meat or poultry (e.g., temperature, sealing time).

3. Loading:

– Place meat or poultry products onto the conveyor or loading area.

– Ensure products are spaced appropriately to avoid overcrowding.

4. Packaging:

– Start the machine. Products will be automatically wrapped and sealed.

– Monitor the process to ensure consistent operation.

5. Sealing and Labeling:

– The machine will seal the packages. Ensure seals are secure to prevent contamination.

– Labels can be applied automatically if the machine has this feature. Otherwise, apply them manually.

6. Inspection and Storage:

– Inspect the packaged products for any defects.

– Store the finished packages in a clean, refrigerated area until they’re ready for distribution.

7. Maintenance:

– Regularly perform maintenance tasks like cleaning, checking for wear and tear, and replacing consumables.

Safety Tips:

– Always follow the manufacturer’s instructions.

– Use protective gear (gloves, aprons).

– Ensure all safety guards are in place and functioning.

By following these steps and ensuring proper maintenance, meat and poultry packaging machines can efficiently package products while maintaining hygiene and safety standards.

List Properties and Terms of “meat and poultry packaging machines”

Meat and poultry packaging machines are specialized equipment designed to efficiently package various meat products to ensure freshness, hygiene, safety, and extended shelf life. These machines come with a variety of properties and functionalities that cater to different meat packaging requirements.

### Properties:

1. Automated Operation: Most machines feature automation to reduce labor costs and improve consistency and speed.

2. Material Compatibility: They are compatible with various packaging materials such as plastic, foil, and vacuum bags.

3. Sealing Capability: Advanced sealing mechanisms ensure airtight packaging, often involving heat sealing, vacuum sealing, or modified atmosphere packaging (MAP).

4. Hygiene and Sanitation: Designed with food-grade materials, easy-clean structures, and compliant with regulatory standards like FDA, USDA, and HACCP.

5. Customizability: Machines can be tailored to different meat products, from ground meat to sausages, poultry cuts, and whole birds.

6. Durability and Reliability: Built with robust materials to withstand the rigors of meat processing environments.

7. Precision and Control: Equipped with sensors and controls for precise weighing, cutting, and packaging.

### Terms:

1. Vacuum Packaging: Removes air from the package to extend shelf life.

2. Modified Atmosphere Packaging (MAP): Replaces the air inside the packaging with a specific gas mixture to extend freshness.

3. Thermoforming: Involves shaping plastic films into custom containers for packaging.

4. Flow Wrap: A packaging technique where the product is enclosed in a plastic film that is sealed and cut.

5. Tray Sealing: Uses pre-formed trays and seals them with a film cover, commonly used for fresh or processed meats.

6. Labeling and Coding: Adds essential information like expiry dates, batch numbers, and product information.

7. Shrink Packaging: Utilizes heat to shrink plastic film tightly around the product.

8. Horizontal and Vertical Form Fill Seal (HFFS/VFFS): Machines that form a package, fill it with product, and then seal it in one continuous process.

These advanced meat and poultry packaging machines ensure efficiency, safety, and quality in meat processing operations.

List The Evolution history of “meat and poultry packaging machines”

The journey of meat and poultry packaging machines reflects significant advancements in technology and industry needs over the past century.

In the early 20th century, meat packaging was largely manual, involving butchers wrapping meat by hand using simple paper wraps. Preservation relied heavily on ice and later refrigeration.

By the 1920s and 1930s, the advent of mechanical refrigeration and improved transportation methods revolutionized meat distribution. Simple mechanical packaging machines started to emerge, facilitating faster and more hygienic processes.

The mid-20th century marked a breakthrough with the introduction of vacuum packaging. The 1950s saw the development of vacuum sealers, which extended shelf life by removing air that causes spoilage. This period also saw the rise of polyethylene film, which offered better sealing properties than traditional materials.

In the 1960s and 1970s, automation began to play a significant role. Machines such as form-fill-seal and thermoformers streamlined operations, allowing meat and poultry products to be packaged more efficiently and consistently.

The 1980s and 1990s brought further automation and the integration of computerized controls, enhancing precision and reducing labor costs. Modified Atmosphere Packaging (MAP) technology emerged, allowing manufacturers to replace the air inside packages with a specific gas mix to keep products fresh longer.

Entering the 21st century, the focus shifted to sustainability, safety, and convenience. Innovations include high-pressure processing (HPP), which extends shelf life and ensures food safety without heat treatment, and smart packaging that can monitor freshness.

Today, advanced robotics, artificial intelligence (AI), and Internet of Things (IoT) technologies are setting new standards. Modern machines are now capable of real-time data monitoring, predictive maintenance, and sophisticated automated systems that ensure high efficiency, quality, and traceability.

This evolutionary path reflects the industry’s response to changing consumer demands, technological advancements, and the ongoing quest for greater efficiency and sustainability in food packaging.

How to Select a Reliable meat and poultry packaging machines

Selecting a reliable meat and poultry packaging machine involves careful consideration of several key factors:

1. Machine Type: Different products may require different packaging types, such as vacuum packaging, modified atmosphere packaging (MAP), or skin packaging. Choose a machine that suits your product needs.

2. Production Volume: Ensure the machine can handle your required throughput. High-volume operations need robust, high-speed machines, while smaller operations might focus on versatility.

3. Hygiene Standards: Meat and poultry packaging must adhere to strict sanitary standards. Look for machines made from stainless steel and designed for easy cleaning to prevent contamination.

4. Flexibility and Adaptability: Consider machines that can handle various packaging formats and sizes, allowing you to adjust to market demands without needing new equipment.

5. Automation and Integration: Advanced features like automated controls, data tracking, and integration with existing production lines can enhance efficiency and reduce labor costs.

6. Brand Reputation and Reviews: Research manufacturers with a strong track record in the meat and poultry industry. User reviews and case studies can provide insights into machine reliability and performance.

7. Technical Support and Service: A reliable after-sales service and readily available spare parts are crucial. Choose a supplier with a solid support network to minimize downtime.

8. Energy Efficiency: Modern machines often come with energy-efficient features, reducing operational costs and environmental impact.

9. Compliance with Regulations: Ensure the machine complies with relevant food safety and packaging standards, such as FDA or EU regulations.

10. Cost-Benefit Analysis: While initial costs are important, consider long-term value, including operational efficiency, maintenance costs, and lifespan.

Conduct thorough research, request demonstrations, and consult with industry experts or peers to make an informed decision.

List “meat and poultry packaging machines” FAQ

### Meat and Poultry Packaging Machines FAQ

1. What types of packaging machines are available for meat and poultry?

There are several types, including vacuum sealers, tray sealers, thermoforming machines, and modified atmosphere packaging (MAP) machines. Each serves different packaging needs and shelf-life requirements.

2. What materials are commonly used for packaging?

Common materials include polyvinyl chloride (PVC), polyethylene (PE), polyethylene terephthalate (PET), and various barrier films designed to extend shelf life and protect the product.

3. How does vacuum packaging work?

Vacuum packaging removes air from the package before sealing, reducing oxygen levels and thereby slowing down the growth of aerobic bacteria and molds, which extends shelf life.

4. What is Modified Atmosphere Packaging (MAP)?

MAP involves altering the atmosphere inside the package, typically replacing oxygen with gases like nitrogen or carbon dioxide. This helps in preserving the color, flavor, and texture of the meat or poultry.

5. How do tray sealers function?

Tray sealers use a heated film to seal pre-formed trays containing meat or poultry. Some models also allow for gas flushing (MAP) to extend shelf life further.

6. Are these machines easy to operate?

Most modern machines come with user-friendly interfaces, often featuring touch-screen controls and automated settings, making them relatively easy to operate.

7. What are the maintenance requirements?

Regular maintenance includes cleaning all contact surfaces, checking and replacing worn parts, and ensuring that the sealing mechanisms remain in good working order. Many manufacturers provide maintenance schedules and guidelines.

8. How is safety ensured?

Most packaging machines are built with safety features like emergency stop buttons and protective guards to prevent accidents. They also often meet industry standards and regulations for food safety.

9. Can these machines handle high volumes?

Yes, industrial-grade machines are designed to handle high output, making them suitable for large-scale meat and poultry processing facilities.

10. What are the benefits of using these machines?

Key benefits include extended shelf life, improved product safety, enhanced presentation, and reduced waste. Efficient packaging also often leads to cost savings in the long run.

Top 10 FAQ with answer about meat and poultry packaging machines for Buyer Sourcing from China

Sure, here are the top 10 frequently asked questions about meat and poultry packaging machines for buyers sourcing from China, along with concise answers:

1. What types of meat and poultry packaging machines are available?

– Options include vacuum sealers, modified atmosphere packaging (MAP) machines, shrink wrap machines, skin pack machines, and thermoformers.

2. How do I ensure the quality of packaging machines from China?

– Look for manufacturers with ISO 9001 certification, request product samples, read customer reviews, and consider a factory audit or third-party inspection.

3. What is the lead time for delivery?

– Typical lead times range from 30 to 60 days, depending on machine complexity and order size. Custom machines may take longer.

4. What are the common power requirements for these machines?

– Most machines operate on 220V, 50/60Hz. Confirm compatibility with your local electrical standards before purchase.

5. Can the machines handle various packaging materials?

– Yes, many machines are compatible with multiple materials such as plastic, film, and laminates. Ensure to check specific material compatibility with the supplier.

6. Are replacement parts readily available?

– Reputable manufacturers provide a list of available spare parts. Confirm the availability and lead times of these parts before purchasing.

7. What are the warranty terms?

– Warranties typically range from 1 to 2 years. Clarify the extent of coverage, including parts and labor, and any conditions for warranty claims.

8. Do suppliers offer after-sales support?

– Many suppliers provide training, installation support, and remote troubleshooting. Ensure the level of support aligns with your needs.

9. How cost-effective are these machines compared to local suppliers?

– While initial costs may be lower, factor in shipping, customs duties, and potential service costs. A comprehensive cost analysis will give a clearer comparison.

10. What certifications do these machines need to comply with international standards?

– Look for machines that comply with CE, UL, and FDA standards to ensure they meet international regulatory requirements.

These FAQs should help streamline your sourcing process and ensure you select the right packaging machines from China.