List Technical Parameters of “salad packaging machine”

Salad packaging machines are specialized devices that are designed to pack salad in a safe and hygienic manner. The use of these machines ensures the freshness of the salad is preserved while also ensuring that harmful pathogens are kept at bay. They achieve this by incorporating various technical parameters, such as:

1. Machine speed: Salad packaging machines come in different speeds ranging from 30 to 50 packs per minute. Factors that affect machine speeds include salad type, packaging materials, and the packaging style.

2. Automated feeding: A feeding system that automatically loads salad onto the conveyor belt is a critical parameter of salad packaging machines. Efficient feeding system ensures a smooth and efficient packaging process.

3. Packaging material: Salad packaging machines utilize different types of packaging materials such as polyurethane, plastic, and aluminum. The material chosen depends on the salad’s characteristics and the desired shelf life.

4. Packaging style: Salad packaging machines use various styles of packaging, including vacuum sealing, heat sealing, and modified atmosphere packaging (MAP). The choice of packaging style depends on the type of salad being packed and the desired shelf life.

5. Weighing system: Some salad packaging machines incorporate weighing systems that ensure salads are packaged at correct weight or volume.

6. Control system: Salad packaging machines feature a control system that regulates the packaging process, including sealing, temperature, and humidity.

7. Hygiene measures: Salad packaging machines are designed to adhere to hygiene standards, such as stainless steel surfaces, easy-to-clean components, and machine safety features.

8. Power requirements: Salad packaging machines require a source of power. It ranges from 220V to 440V and depends on the machine capacity and manufacturer.

Salad packaging machines are essential in ensuring the freshness, safety, and hygiene of salads. These technical parameters ensure efficient packing operations, preserving the quality of the salad from farm to table.

List Product features of “salad packaging machine”

Product features of a salad packaging machine include:

1. Versatile Packaging Options: The salad packaging machine offers a wide range of packaging options to fit various salad sizes, shapes, and weights. It can handle different types of salad bowls, trays, or bags, providing flexibility to meet the specific needs of different salad producers.

2. Automated Packaging Process: The machine is equipped with advanced automation technology, streamlining the packaging process. It can automatically feed, fill, seal, and label the salad containers, reducing manual labor and enhancing efficiency.

3. Adjustable Portion Control: The salad packaging machine allows for precise portion control, ensuring consistency in salad packaging. It can accurately measure the desired quantity of salad, minimizing waste and maximizing profitability.

4. Seal Integrity and Freshness: The machine ensures high seal integrity and freshness of the packaged salads. It utilizes innovative sealing techniques, such as heat sealing or vacuum sealing, to create a secure seal that preserves the freshness, flavor, and nutritional value of the salads.

5. Hygienic Design: The machine is designed with strict hygiene standards in mind. It features easy-to-clean surfaces and materials that are resistant to corrosion and bacterial growth, ensuring food safety and compliance with health regulations.

6. Advanced Controls and Monitoring: The salad packaging machine is equipped with advanced control systems that offer user-friendly interfaces. Operators can easily set parameters, monitor the packaging process, and make adjustments as needed. It may also include smart sensors to detect any errors or anomalies in real-time, preventing packaging defects.

7. Integration with Existing Production Lines: The machine is designed to seamlessly integrate with existing salad production lines. It can be easily retrofitted into the production process, minimizing disruption and maximizing the utilization of existing infrastructure.

8. Energy Efficiency: The salad packaging machine is designed to be energy-efficient, minimizing energy consumption and reducing environmental impact. It may incorporate energy-saving features such as automatic standby mode or efficient motors.

9. Compact Footprint: The machine is designed with a compact footprint to optimize space utilization, especially in crowded production facilities. Its small size allows it to fit into tight spaces while still maintaining high throughput.

10. Reliable Performance and Maintenance: The salad packaging machine is built with durable components and reliable mechanisms, ensuring a long lifespan and minimal downtime. It may include predictive maintenance features that provide alerts and reminders for routine maintenance, avoiding unexpected breakdowns.

Overall, the salad packaging machine offers a range of features that optimize productivity, quality, and efficiency in the packaging process, making it an essential tool for salad producers.

List Application of “salad packaging machine”

Salad packaging machines have become quite popular in recent times. These machines use advanced technology to pack salads and ensure that they remain fresh for a long time. They are used in supermarkets, grocery stores, and restaurants, among other places. Below are some of the applications of salad packaging machines.

1. Supermarkets and Grocery stores

Salad packaging machines are commonly used in supermarkets and grocery stores to pack pre-cut and washed salad. This enables the stores to cater to customers who are looking for a quick and healthy meal option. The machines can pack a variety of salad mixes, including lettuce, spinach, and kale, among others.

2. Restaurants and Cafes

Restaurants and cafes use salad packaging machines to pack salads for takeaways and delivery orders. These machines come in different sizes, making them ideal for small and large restaurants. They help restaurant owners maintain consistency and quality in their salads, which is crucial to customer satisfaction.

3. Food Processing Plants

Large scale food processing plants use salad packaging machines to pack salad mixes in bulk. The machines can handle large volumes of salad mixes, ensuring that they are packed and sealed efficiently. This helps businesses to reduce labor costs and increase production efficiency.

4. Home Delivery Services

Salad packaging machines are also used by home delivery services that offer pre-cut salads for customers. These machines help to maintain the freshness of salads during transport, ensuring that they reach customers in good condition. This is beneficial for small businesses that offer home delivery services.

5. Airline Catering

Airline catering companies use salad packaging machines to pack pre-cut salads for in-flight meals. The machines help to ensure that the salads remain fresh and hygienic during flights, which is crucial for health reasons. The machines can handle large volumes of salad, making them suitable for use in airline catering.

In conclusion, salad packaging machines have numerous applications in businesses that deal with salads. They help to ensure that salads are fresh and hygienic, making them an essential tool for businesses that want to maintain quality and consistency in their products.

List Various Types of “salad packaging machine”

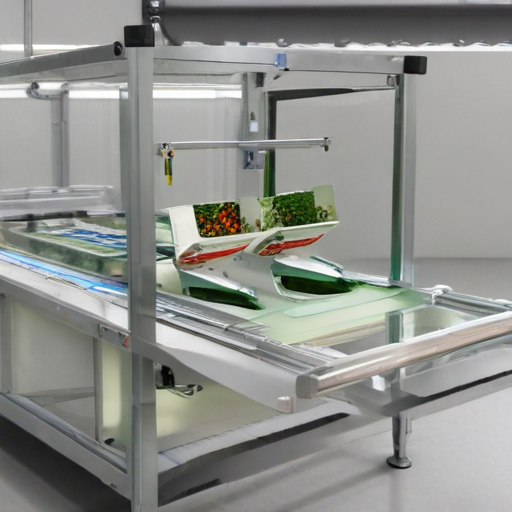

There are several types of salad packaging machines available in the market, each designed to suit different packaging requirements and production needs. These machines ensure efficient and hygienic packaging of salads, extending their shelf life and maintaining their freshness. Here are some popular types of salad packaging machines:

1. Bagging machines: These machines are equipped with automatic bagging systems that measure and fill salads into plastic bags. They can handle various bag types, including pouches, gusseted bags, and vacuum-sealed bags.

2. Clipping machines: Clipping machines are used to secure the bags filled with salads by applying clips or fasteners. They ensure the proper sealing of bags, preventing air and moisture from entering and compromising the quality of the salad.

3. Tray sealing machines: These machines are designed to package salads in plastic trays, which are then sealed with a plastic film. The film provides a protective barrier and keeps the salad fresh. Tray sealing machines can handle different tray sizes and shapes.

4. Vertical form-fill-seal machines: These machines are capable of forming, filling, and sealing bags in a vertical orientation. They can package salads in a variety of bag styles, including stand-up pouches, pillow bags, and quad seal bags.

5. Flow wrap machines: Flow wrapping is a packaging technique that uses a continuous roll of film to tightly seal salads. Flow wrap machines are suitable for packaging individual salad portions or smaller salad packs. They provide airtight packaging and extend the salad’s shelf life.

6. Cartoning machines: Cartoning machines automate the process of placing salad bags or trays into cartons. They also fold and seal the cartons, ready for distribution. These machines are ideal for high-volume salad packaging operations.

7. Labeling machines: Labeling machines apply labels to salad packaging to provide important information such as ingredients, nutritional facts, and expiry dates. They can handle different label sizes and colors, ensuring accurate and consistent labeling.

It is important to consider factors such as production volume, packaging requirements, and budget when selecting a salad packaging machine. Each type of machine offers specific functionalities, and manufacturers can choose the most suitable one based on their needs. These machines streamline the packaging process, reduce labor costs, and ensure that salads reach consumers in optimal condition.

Custom Manufacturing Options for salad packaging machine

When looking for custom manufacturing options for a salad packaging machine, there are a few key considerations to keep in mind. The machine should be able to efficiently handle the packaging process, maintain the freshness and quality of the salad, and be user-friendly for operators. Here are some custom manufacturing options to consider:

1. Automated Salad Packaging: Look for a manufacturer that specializes in automated packaging machines specifically designed for salad products. These machines can efficiently handle the various components of salad packaging, including weighing, bagging, sealing, and labeling. They should have the ability to accommodate different salad types, sizes, and packaging materials.

2. Modified Atmosphere Packaging (MAP): MAP technology involves modifying the atmosphere inside the packaging to extend the shelf life of the salad. The system can flush out oxygen and replace it with a gas mixture that slows down the salad’s deterioration process. Custom manufacturing options should include MAP capabilities, ensuring the salads remain fresh and appealing for longer periods.

3. Versatility and Flexibility: Opt for a custom salad packaging machine that offers versatility and flexibility to accommodate different salad packaging requirements. This includes the ability to handle different salad sizes, formats (such as bowls or bags), and packaging materials (such as plastic or compostable materials). The machine should also allow for easy adjustments and quick changeovers between different salad types, reducing downtime and increasing productivity.

4. Hygiene and Food Safety: Custom manufacturing options must prioritize hygiene and food safety. The machine should be designed with materials and features that ensure easy cleaning and sanitation, helping to prevent bacterial contamination and cross-contamination between different salad batches. Look for options with stainless steel constructions and smooth surfaces to facilitate thorough cleaning and compliance with food safety regulations.

5. User-friendly Interface: A user-friendly interface is essential to streamline operation and reduce the learning curve for operators. The machine should have an intuitive control panel that allows for easy adjustments, monitoring of production, and troubleshooting. Customizable settings should include bag sizes, weight accuracy, customization of labels, and other relevant parameters.

When exploring custom manufacturing options for a salad packaging machine, it is crucial to partner with a reputable manufacturer with experience in producing similar equipment. They should be able to understand your specific requirements and customize the machine accordingly, ensuring efficient and reliable packaging of your salad products.

List Quality Control and The Manufacturing Process of “salad packaging machine”

The quality control and manufacturing process of a salad packaging machine is vital to ensure efficiency, accuracy, and reliability in the production of salad packaging. A well-implemented quality control process can help identify and rectify any defects or flaws in the machine, ensuring that it meets the desired standards and specifications.

The first step in the manufacturing process is designing the salad packaging machine. This involves extensive research, engineering, and prototyping to develop a machine that can efficiently package various types of salads in a hygienic and visually appealing manner. Design specifications are drafted, including requirements for speed, precision, packaging material compatibility, and user-friendly operation.

Once the design phase is complete, the manufacturing process commences. High-quality materials, such as food-grade stainless steel, are used to construct the various components of the machine. Each component undergoes meticulous machining, cutting, and shaping to ensure accuracy and compatibility.

The assembly phase is a critical stage, where individual components are integrated to form a complete salad packaging machine. Skilled technicians follow precise assembly instructions to ensure that every part fits together correctly. Additionally, regular quality checks are conducted during assembly to identify any faults or deviations from the intended design.

After assembly, the machine undergoes rigorous testing and quality control processes. Various tests are conducted to evaluate the machine’s performance, such as speed and accuracy of packaging, product consistency, and adherence to safety standards. This involves simulating real-world operating conditions to identify any potential issues and rectify them before the machine is ready for production.

To guarantee continuous quality control during production, regular maintenance and calibration of the machine are necessary. Technicians conduct routine inspections, cleaning, and lubrication to ensure that the machine operates optimally throughout its lifespan. Any wear and tear or malfunctions are promptly addressed to prevent any potential defects in the salad packaging.

In conclusion, the quality control and manufacturing process of a salad packaging machine involves designing, manufacturing, assembly, testing, and regular maintenance. These stages aim to ensure the machine’s efficiency, accuracy, and reliability in packaging salads. Adhering to stringent quality control measures guarantees that the machine meets the required standards and specifications, ensuring customer satisfaction and success in the salad packaging industry.

How to use “salad packaging machine”

Using a salad packaging machine can improve efficiency and reduce labor costs for businesses involved in salad production. Here is a step-by-step guide on how to use a salad packaging machine:

1. Set up the machine: Ensure the packaging machine is placed on a sturdy, stable surface. Connect it to a power source and make sure it is correctly assembled as per the manufacturer’s instructions.

2. Prepare the packaging materials: Depending on the machine used, it may require specific packaging materials such as plastic bags or trays. Ensure you have an adequate supply of these materials and have them prepared nearby.

3. Wash and clean the salad: Before packaging, properly wash and clean the salad ingredients to ensure they are free from dirt, debris, and bacteria. Allow them to dry or use a salad spinner to remove excess water.

4. Calibrate the machine: Adjust the settings on the salad packaging machine according to the type and quantity of salad being packaged. This includes portion size, sealing strength, and labeling parameters.

5. Load the salad: Place the washed and calibrated salad ingredients into the designated filling area. Ensure the quantity doesn’t exceed the machine’s capacity to avoid jams or other malfunctions.

6. Activate the machine: Start the packaging process by pressing the appropriate buttons or switches. The machine will automatically start weighing the salad, sealing the packaging, and labeling if applicable. Monitor the packaging process to ensure it is functioning properly.

7. Inspect the packaged salad: Once the machine completes the packaging process, carefully inspect the sealed salads for any defects or irregularities. Remove any faulty packages and set them aside.

8. Label and store: If necessary, label the packaged salads with appropriate information such as date of packaging, ingredients, or expiration date. Store the packaged salads in appropriate storage conditions such as a refrigerator or controlled environment.

9. Clean and maintain the machine: After each use, clean the salad packaging machine thoroughly to prevent cross-contamination and ensure optimal performance. Follow the manufacturer’s instructions for maintenance and periodic servicing.

10. Troubleshooting: In case of any issues with the salad packaging machine, consult the user manual or contact the manufacturer’s customer support for guidance on troubleshooting and repairs.

By following these steps, you can effectively use a salad packaging machine to streamline the packaging process, maintain the salad’s freshness, and meet the demands of salad production efficiently.

List Properties and Terms of “salad packaging machine”

A salad packaging machine is a specialized machinery used in the food industry to automate the process of packaging salads. It is designed to handle delicate salad components efficiently while maintaining their freshness and quality. Some properties and terms associated with salad packaging machines include:

1. Automated Operation: Salad packaging machines are equipped with advanced automation technology, enabling them to perform various tasks such as sorting, weighing, filling, sealing, and labeling. This eliminates the need for manual labor, reducing costs and increasing productivity.

2. Hygiene and Sanitation: These machines are constructed using food-grade materials and feature a closed, clean, and sterile environment to ensure the hygiene and safety of the packed salads. They are often equipped with features like stainless steel construction, easy-to-clean surfaces, and air purification systems.

3. Customization and Flexibility: Salad packaging machines offer customizable options to cater to different types of salads, packaging sizes, and formats. They can accommodate various bag or container sizes, including bowls, trays, or pouches, and can be easily adjusted to meet specific customer requirements.

4. Weighing and Portioning: Salad packaging machines come with built-in weighing systems that accurately measure the desired portion of each salad component. This ensures consistency in portion sizes and minimizes product waste. The machines can also be programmed to achieve the desired salad-to-dressing ratio.

5. Gentle Handling: Salad packaging machines employ gentle handling mechanisms, such as vibratory feeders and soft conveyors, to prevent damage or bruising to the delicate salad ingredients. They are designed to handle leafy greens, vegetables, fruits, and herbs with care, maintaining their visual appeal and freshness.

6. Quality Control: These machines are equipped with quality control features, such as vision systems and sensors, to detect and remove any defective or contaminated salad components. They also ensure accurate placement of labels, barcodes, or expiration dates on the packaging for traceability and regulatory compliance.

7. Efficiency and Speed: Salad packaging machines are designed to operate at high speeds, increasing production rates and meeting market demands. They can process a large volume of salads per minute, reducing the overall production time and enabling faster packaging cycles.

8. Integration with Production Lines: Salad packaging machines can be seamlessly integrated into existing production lines, allowing for continuous flow and synchronization with other processes such as salad preparation, washing, and cutting.

Overall, salad packaging machines provide an efficient and reliable solution for automating the packaging process of salads, ensuring product quality, and improving productivity in the food industry.

List The Evolution history of “salad packaging machine”

The evolution of salad packaging machines has seen remarkable advancements over the years, streamlining the packaging process and ensuring the freshness and quality of salads.

In the early years, salad packaging was a manual and time-consuming task. Workers had to wash, cut, and assemble the salad components by hand. Packaging involved placing the salad mix into plastic containers, which were then sealed with lids using manual methods. This process was labor-intensive and prone to human errors.

As technology progressed, semi-automatic salad packaging machines emerged. These machines simplified the packaging process by automating certain tasks. They could wash, dry, and cut lettuce leaves, and also incorporate other salad ingredients. Although these machines significantly improved efficiency and reduced labor requirements, they still required manual intervention for loading and unloading the salad components.

The next major leap came with the introduction of fully automatic salad packaging machines. These machines revolutionized the industry by automating the entire packaging process. They incorporated advanced sensors and robotics to handle tasks such as washing, cutting, weighing, and packaging the salad components. This innovative technology ensured precision and consistency in portioning the salad ingredients, resulting in uniform and appealing packaging. These machines also enhanced food safety measures by minimizing the risk of contamination.

Additionally, modern salad packaging machines are equipped with advanced features to extend the shelf life of salads. They incorporate vacuum packing, modified atmosphere packaging (MAP), and other technologies to create a controlled environment inside the packaging, thus preserving the freshness and prolonging the shelf life of the salad mix.

Furthermore, the latest advancements in packaging machine technology have introduced intelligent control systems. These systems allow for real-time monitoring and adjustments of the machine’s operations, optimizing efficiency and reducing waste.

In conclusion, the evolution of salad packaging machines has progressed from manual labor to semi-automatic and ultimately to fully automatic systems. These machines have greatly improved efficiency, precision, and food safety in the packaging process. With further advancements, such as intelligent control systems, the future of salad packaging machines looks promising, ensuring even greater efficiency and quality in the years to come.

How to Select a Reliable salad packaging machine

Selecting a reliable salad packaging machine is crucial for businesses in the food industry. To ensure that you make the right choice, consider the following factors:

1. Production Capacity: Determine your required production capacity based on the volume of salad you need to package. Look for a machine that can handle the desired output efficiently without compromising on quality.

2. Packaging Requirements: Assess your packaging needs, such as the type of salad packaging (e.g., bags, containers), packing dimensions, and sealing methods. Ensure that the machine you choose can accommodate these specifications.

3. Durability and Construction: Choose a machine made from high-quality materials that are durable and easy to clean. This will ensure longevity and hygiene, preventing any contamination risks.

4. Automation and User-Friendliness: Consider the level of automation you require. Fully automated machines can streamline operations and increase productivity. Look for user-friendly interfaces that are easy to operate, reducing the need for extensive training.

5. Customization Options: Check whether the machine offers customization options to adapt to different salad sizes, shapes, or packaging materials. This will give you the flexibility to adjust your packaging according to market demands.

6. Maintenance and Support: Research the manufacturer’s reputation for after-sales service, availability of spare parts, and technical support. A reliable supplier with a reliable support team can ensure minimal downtime and quick resolution of any issues.

7. Cost and Return on Investment: While cost is a crucial factor, focus on the long-term return on investment, rather than just the upfront price. Evaluate the machine based on its productivity, efficiency, and durability, ensuring that it aligns with your business budget and goals.

Once you have narrowed down your choices, consider seeking feedback and recommendations from industry experts, reading customer reviews, and even visiting manufacturing facilities to see the machines in action. This thorough research will help you select a reliable salad packaging machine that meets your specific needs, ensures product integrity, and contributes to your business’s success.

List “salad packaging machine” FAQ

FAQ: Salad Packaging Machine

1. What is a salad packaging machine?

A salad packaging machine is a specialized machine designed to automate the process of packaging salads. It is equipped with various modules and features designed to efficiently wash, cut, dry, and package salad products.

2. How does a salad packaging machine work?

The machine typically starts by feeding the salad ingredients into the washing module, where they are thoroughly cleaned. Then, the ingredients are moved to the cutting module, where they are sliced or diced to the desired size. After cutting, the salad is moved to the drying module, where excess moisture is removed. Finally, the machine packages the salad, either by placing it into bags, containers, or trays, and seals them for retail distribution.

3. What are the benefits of using a salad packaging machine?

Using a salad packaging machine offers several benefits. Firstly, it increases productivity and efficiency by automating the time-consuming and labor-intensive tasks involved in salad preparation. Secondly, it improves hygiene and food safety by ensuring the ingredients are thoroughly washed and dried. Thirdly, it enhances the visual appeal of the packaged salads, thus attracting customers and increasing sales. Additionally, the machine reduces waste and optimizes portion control, leading to cost savings for businesses.

4. Can a salad packaging machine handle different types of salads?

Yes, most salad packaging machines are versatile and can handle various types of salads, including leafy greens, mixed vegetable salads, fruit salads, and more. The machine can be programmed to adjust cutting sizes, packaging styles, or other parameters, depending on the specific salad being processed.

5. Is the machine easy to clean and maintain?

Yes, salad packaging machines are designed to be easy to clean and maintain. They often include features such as removable parts, quick-release mechanisms, and washable conveyor belts, making the cleaning process straightforward. Regular maintenance procedures, such as lubrication, inspection, and parts replacement as needed, should be followed to ensure optimal performance and longevity of the machine.

6. Is training required to operate a salad packaging machine?

While salad packaging machines are designed to be user-friendly, some level of training is recommended to operate these machines safely and efficiently. Manufacturers typically provide training sessions or manuals to familiarize operators with the machine’s functionality, maintenance, and troubleshooting procedures.

In conclusion, a salad packaging machine is a highly efficient and versatile machine that automates the process of packaging salads. It offers numerous benefits through increased productivity, improved hygiene, enhanced visual appeal, waste reduction, and portion control. With easy cleaning and maintenance requirements, along with some initial training, these machines are a valuable addition to the food packaging industry.

Top 10 FAQ with answer about salad packaging machine for Buyer Sourcing from China

1. What is a salad packaging machine?

A salad packaging machine is a specialized machine designed for packing pre-made salads. It includes different modules such as a weigher, filling module, sealing module, and labeling module, and can pack salads in various packaging materials and sizes.

2. What types of salad packaging machines are there?

There are mainly two types of salad packaging machines – automatic and semi-automatic. An automatic machine can handle a higher volume of production and requires less manual intervention, while a semi-automatic machine is suitable for small to medium scale production.

3. What is the production capacity of salad packaging machines?

The production capacity of a salad packaging machine depends on the type and model of the machine. Generally, an automatic machine can pack up to 60 packs per minute, while a semi-automatic machine can pack up to 30 packs per minute.

4. What packaging materials can a salad packaging machine handle?

Salad packaging machines can handle different types of packaging materials such as plastic bags, paper bags, pouches, and trays. The packaging material depends on how long the salad needs to stay fresh and the presentation one chooses.

5. What features should I look for in a salad packaging machine?

Factors like production speed, packaging materials, hygiene standards, and after-sales services should be taken into consideration while choosing a salad packaging machine. In addition, customizable options, like branding and presentation, may be important to consider for small businesses.

6. How can I ensure the quality of a salad packaging machine from a Chinese supplier?

Always make sure to do thorough research and select a reputable supplier with good customer reviews. Choose a supplier that has passed certifications like CE, ISO, and FDA. Have detailed communication with them about your personalized requirements.

7. What are the shipping and delivery options for salad packaging machines from China?

Delivery options typically include air or sea freight. The shipping method may vary based on the volume, urgency, and cost of your order. Multiple options are available, so discuss with your supplier to arrange the best option for you.

8. What is the price range of salad packaging machines from China?

The price of a salad packaging machine from China can vary depending on the type, model, and production capacity of the machine. Generally, the price range for a salad packaging machine can be $2,500 to $30,000.

9. What are the payment terms for salad packaging machine orders from Chinese suppliers?

Payment options can include bank transfers, online payment, letter of credit, and other secure methods. However, the payment term depends entirely upon the supplier and can vary depending on order size and payment credibility.