List Technical Parameters of “vertical form fill seal machines”

Vertical form fill seal (VFFS) machines are highly versatile and efficient packaging systems used across various industries. Here are the key technical parameters:

1. **Machine Speed**: VFFS machines’ speed is typically measured in bags per minute (BPM). Modern machines can achieve speeds ranging from 20 to over 200 BPM, depending on package size and product characteristics.

2. **Bag Dimensions**: The machine must accommodate a range of bag widths and lengths. Widths can range from 50mm to 400mm or more, and lengths can vary from 60mm to 600mm.

3. **Film Type and Width**: VFFS machines work with various materials including PE, PP, laminates, and other heat-sealable films. Maximum film width is dictated by the machine’s design, typically up to 1200 mm.

4. **Product Categories**: They can handle powders, granules, liquids, and solids, which influences the filling and dosing mechanism (e.g., auger fillers for powders, volumetric cups for granules).

5. **Sealing Mechanism**: Options include heat sealing, ultrasonic sealing, or cold sealing. Factors like sealing time, temperature, and pressure are critical for consistent and leak-proof seals.

6. **Bag Styles**: These machines can create different types of bags, such as pillow bags, gusseted bags, flat-bottom bags, and quad seal bags.

7. **Dosing Accuracy**: Ensures precise filling with minimal product wastage, essential for maintaining product consistency and meeting regulatory requirements.

8. **Control System**: Includes PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) ensuring easy operation, real-time monitoring, and quick adjustments.

9. **Power Supply**: Machines typically operate on 220-240V/380V, 50/60 Hz electrical power and have varying power consumption based on their capacity and functionality.

10. **Construction Materials**: Often made from stainless steel to meet hygiene standards, especially for food and pharmaceutical applications.

11. **Optional Features**: Includes gas flushing, hole-punching, tear notches, labeling, and inline printing for improved convenience and functionality.

These parameters ensure the VFFS machines provide efficient, reliable, and flexible packaging solutions tailored to diverse industrial needs.

List Product features of “vertical form fill seal machines”

Vertical Form Fill Seal (VFFS) machines are advanced packaging systems known for their versatility and efficiency. Here are some key product features:

1. **Automated Operation**: VFFS machines automate the process of forming, filling, and sealing bags which enhances productivity and reduces labor costs.

2. **Versatility**: They can handle a wide range of packaging materials such as plastics, laminates, and paper, and cater to diverse product types, including liquids, powders, granules, and solids.

3. **Precision Filling**: The machines employ advanced dosing systems like augers, scales, or volumetric cups to ensure accurate and consistent filling quantities.

4. **High-Speed Production**: Capable of achieving high output rates suitable for large-scale production needs, these machines support rapid packaging speeds.

5. **Customization**: Configurable to create various bag styles such as pillow bags, gusseted bags, stand-up pouches, and block bottom bags, with options for resealable features like zippers.

6. **User-Friendly Interface**: Equipped with intuitive control panels and touchscreen interfaces that facilitate easy operation and programming.

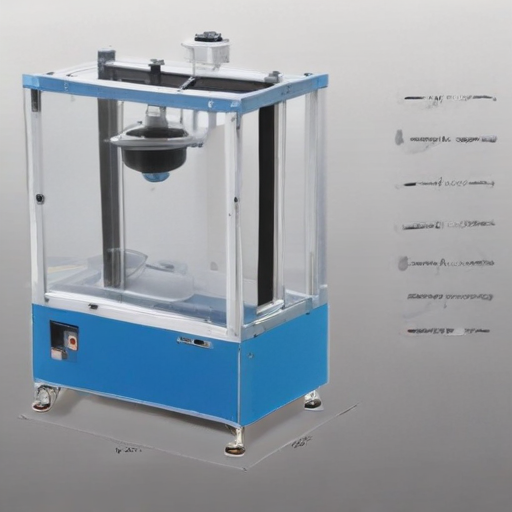

7. **Compact Design**: Space-saving design that integrates forming, filling, and sealing in a vertical arrangement, making it suitable for facilities with limited floor space.

8. **Modularity**: Many VFFS machines offer modular components, enabling easy upgrades and maintenance, as well as adaptability to changing production requirements.

9. **High-Seal Integrity**: Advanced sealing technologies ensure durable seals that protect the product’s freshness and quality.

10. **Hygienic Construction**: Made from stainless steel and other sanitary materials, they are designed for easy cleaning and meet stringent hygiene standards required in industries like food and pharmaceuticals.

11. **Integration Capabilities**: Compatible with ancillary equipment such as printers, metal detectors, and checkweighers for comprehensive packaging solutions.

These features make VFFS machines a key investment for businesses looking to optimize their packaging operations and ensure product integrity.

List Application of “vertical form fill seal machines”

Vertical Form Fill Seal (VFFS) machines are versatile packaging machines widely used across various industries for packing products efficiently and hygienically. Below are some key applications:

1. **Food Industry**:

– **Snacks**: Potato chips, popcorn, pretzels, and nuts.

– **Powders**: Flour, spices, coffee, and powdered drink mixes.

– **Grains and Rice**: Packaged in bulk or retail sizes.

– **Pasta and Noodles**: Dried pasta and instant noodles.

– **Frozen Foods**: Vegetables, fruits, and prepared meals.

2. **Beverage Industry**:

– **Ground Coffee and Tea**: Various sizes and quantities for consumer and commercial use.

– **Drink Mixes**: Powdered or granular drink mixes.

3. **Pharmaceuticals and Health Products**:

– **Medical Supplies**: Bandages, medical swabs, and IV bags.

– **Dietary Supplements**: Capsules, tablets, and powdered supplements.

4. **Cosmetics and Personal Care**:

– **Facial Masks and Creams**: Single-use facial masks and creams.

– **Bath Salts and Granules**: Packaged for retail use.

5. **Non-Food Consumer Goods**:

– **Detergents and Cleaning Agents**: Powders and granulates for household cleaning.

– **Pet Food**: Dry food and treats.

6. **Industrial Products**:

– **Hardware Components**: Screws, nuts, bolts, and other small parts.

– **Agricultural Products**: Seeds, fertilizers, and pesticides.

7. **Specialty Markets**:

– **Promotional Items**: Sample sizes for marketing campaigns.

– **Small Electronics**: Accessories and spare parts.

The VFFS machines offer advantages such as high-speed production, consistency in packaging, and reduced labor costs. They are favored for their ability to create air-tight and tamper-evident seals ensuring product freshness and safety. Moreover, these machines can handle various types of packaging materials, making them suitable for diverse products and industries.

List Various Types of “vertical form fill seal machines”

Vertical Form Fill Seal (VFFS) machines are critical in the packaging industry for efficiently packing a diverse array of products. Here are various types of VFFS machines, each designed for specific applications:

1. **Continuous Motion VFFS Machines**:

– **High-Speed Operations**: Ideal for high-speed packaging of snacks, candies, and other small items. Continuous motion ensures constant product flow and high efficiency.

– **Industry Examples**: Confections, small hardware items.

2. **Intermittent Motion VFFS Machines**:

– **Stop-and-Start Technology**: Suitable for products that require precise placement or specific sealing configurations.

– **Industry Examples**: Powdered products, granular products like rice and grains.

3. **Multi-Lane VFFS Machines**:

– **Multiple Product Lines**: Capable of handling several product lines simultaneously, increasing output and efficiency.

– **Industry Examples**: Sachets, stick packs for single-serve products like coffee or drink mixes.

4. **Stick Pack VFFS Machines**:

– **Single-Serve Packaging**: Specifically designed for long, slender packages, often used for liquids or powders that require single servings.

– **Industry Examples**: Energy gels, condiment sachets.

5. **Quad Seal VFFS Machines**:

– **Enhanced Stability**: Provides a square or rectangular package with four vertical seals for improved package stability and better shelf presentation.

– **Industry Examples**: Pet foods, bulky snacks.

6. **Pillow Bag VFFS Machines**:

– **Traditional Packaging Style**: Forms a pillow-like package with top and bottom seals, and a vertical back seal.

– **Industry Examples**: Chips, baked goods.

7. **Gusseted Bag VFFS Machines**:

– **Wider Base**: Allows the package to stand upright, providing better shelf display and maximized storage space.

– **Industry Examples**: Coffee, legumes.

8. **Vacuum VFFS Machines**:

– **Shelf-Life Extension**: Removes air from the package before sealing, ideal for perishable goods.

– **Industry Examples**: Cheeses, deli meats.

9. **Liquid VFFS Machines**:

– **Sealing Liquid Products**: Equipped with specialized nozzles and sealing mechanisms for packaging free-flowing liquids.

– **Industry Examples**: Sauces, soups, beverages.

Each type of VFFS machine caters to specific packaging needs and demonstrates the adaptability and efficiency required in modern manufacturing and packaging processes.

Custom Manufacturing Options for vertical form fill seal machines

Vertical form fill seal (VFFS) machines are pivotal in the packaging industry, offering versatile and efficient solutions. Custom manufacturing options can enhance their functionality and meet specific industry requirements. Here are some options to consider:

1. **Material Handling Compatibility**:

– **Flexible Film Options**: Customize machines to handle specific film types like polyethylene, laminated films, or biodegradable materials.

– **Product Types**: Adaptability for liquids, powders, granules, or solids. Include auger fillers, volumetric cups, or liquid pumps.

2. **Speed and Efficiency Enhancements**:

– **High-Speed Capabilities**: Upgrade to support high-speed operations for increased throughput.

– **Automated Controls**: Incorporate PLC systems and HMIs for seamless operation and minimal human intervention.

3. **Sealing Techniques**:

– **Heat Sealing**: Opt for specific sealing patterns and temperature controls to ensure package integrity.

– **Ultrasonic Sealing**: For delicate or heat-sensitive products.

4. **Customization in Package Dimensions**:

– **Adjustable Forming Tubes**: Allow for variable pouch sizes and shapes.

– **Die-Cut Feature**: Create custom shapes for unique packaging needs.

5. **Product-Specific Features**:

– **Gentle Product Handling**: Tailored for fragile items like chips or biscuits.

– **Nitrogen Flushing**: To extend the shelf life of perishable products.

6. **Integrations and Add-ons**:

– **Date Coders and Printers**: For batch coding and traceability.

– **Weighing and Dosing Systems**: Precise product quantity control.

– **Labeling Systems**: Incorporate inline for branding.

7. **Ergonomic and Safety Customizations**:

– **Stainless Steel Construction**: For compliance with food and pharmaceutical standards.

– **Safety Guards and Sensors**: Enhance operator safety and machine longevity.

8. **Post-Packaging Options**:

– **Integrated Conveyor Systems**: For smooth post-sealed package transfer.

– **Secondary Packaging**: Automatic cartoners or case packers for efficient handling.

By leveraging these custom manufacturing options, VFFS machines can be tailored to meet specific operational demands, ensuring efficiency, versatility, and reliability.

List Quality Control and The Manufacturing Process of “vertical form fill seal machines”

**Quality Control of Vertical Form Fill Seal (VFFS) Machines:**

1. **Incoming Inspection:**

– **Raw Materials**: Ensure metals, electronic components, and other materials meet specifications.

– **Supplier Audits**: Evaluate suppliers for consistent quality and compliance.

2. **In-process Inspection:**

– **Precision Measurement**: Use calipers and micrometers to verify component dimensions.

– **Functional Testing**: Check sub-assemblies like servo motors for proper operation.

– **Machine Calibration**: Regularly calibrate machines to ensure accurate filling and sealing.

3. **Final Inspection:**

– **Operational Testing**: Run machines through complete filling and sealing cycles with actual product.

– **Seal Integrity**: Conduct seal strength tests to ensure packaging reliability.

– **Performance Metrics**: Assess for speed, accuracy, and consistency in performance.

4. **Documentation and Traceability:**

– **Record Keeping**: Maintain detailed logs of inspections, test results, and corrective actions.

– **Quality Certificates**: Issue certificates for compliance with industry standards.

**Manufacturing Process of VFFS Machines:**

1. **Design and Engineering:**

– **CAD Modeling**: Develop detailed 3D models and blueprints of components.

– **Prototyping**: Create prototypes for initial evaluations and adjustments.

2. **Material Procurement:**

– **Sourcing**: Obtain high-quality metals, electronics, and parts from certified suppliers.

3. **Component Manufacturing:**

– **Machining**: Fabricate metal parts using CNC machines for high precision.

– **Sheet Metal Processing**: Laser cut and bend sheet metal for machine frames and panels.

4. **Sub-Assembly:**

– **Welding and Joining**: Assemble frames, hoppers, and other structural components.

– **Electronic Assemblies**: Mount and wire control systems, sensors, and actuators.

5. **Main Assembly:**

– **Integration**: Combine sub-assemblies into the main machine structure.

– **Alignment and Adjustment**: Ensure all components are aligned and properly functioning.

6. **Testing and Calibration:**

– **Dry Runs**: Operate machines without product to check mechanical and electronic systems.

– **Product Testing**: Conduct actual product tests to verify filling and sealing accuracy.

7. **Finishing:**

– **Surface Treatments**: Apply coatings or finishes for durability and aesthetics.

– **Labeling and Documentation**: Attach labels, user manuals, and compliance certificates.

8. **Packaging and Shipping:**

– **Secure Packaging**: Protect machines during transit with robust packaging materials.

– **Logistics Coordination**: Arrange transportation to customers, ensuring timely delivery.

How to use “vertical form fill seal machines”

Vertical form fill seal (VFFS) machines are widely used in packaging to automatically form and fill bags with various products. Here’s a concise guide on how to use them:

1. **Setup:**

– **Install Film Roll:** Place the film roll on the unwind spindle. Ensure the film is suitable for the product and machine.

– **Thread Film:** Thread the film through the machine’s rollers, forming collar, and sealing jaws according to the manufacturer’s guide.

– **Adjust Settings:** Set the appropriate bag length, temperature for sealing, and filling parameters through the control panel.

2. **Loading Product:**

– **Filling System:** Connect the filling system (auger filler, multi-head weigher, etc.) to ensure a steady and accurate flow of the product into the machine.

– **Hopper:** Load the product into the hopper, making sure it’s free of clogs and evenly distributed.

3. **Operation:**

– **Start Machine:** Initiate the machine through the control panel. The film will be pulled downward into the machine.

– **Forming Bag:** The film passes over a forming tube, creating a cylindrical shape. The vertical seal bars then seal the film edges together.

– **Filling:** Once the bottom of the bag is sealed, the product is deposited into the formed bag.

– **Sealing and Cutting:** The horizontal seal bars seal the top of the bag and cut it, completing the package.

4. **Monitoring and Adjustments:**

– **Regular Checks:** Frequently monitor the machine for any issues like film misalignment or insufficient sealing.

– **Adjustments:** Make necessary adjustments in real-time using the control panel to maintain optimal performance.

5. **Safety and Maintenance:**

– **Safety Precautions:** Always follow safety guidelines, ensuring the machine is stopped and locked out during maintenance.

– **Regular Maintenance:** Schedule regular maintenance checks to clean, lubricate, and inspect components for wear and tear.

By following these steps, you ensure efficient operation and consistent packaging quality with a VFFS machine.

List Properties and Terms of “vertical form fill seal machines”

Vertical form fill seal (VFFS) machines are versatile packaging equipment primarily used for automatic packing of products in various industries. Here are some key properties and terms associated with VFFS machines:

### Properties:

1. **Vertical Configuration**: Operates with a vertical packaging format, allowing gravity to assist in filling.

2. **Automation**: Fully automated process for forming, filling, and sealing packages.

3. **Speed**: High-speed operation suitable for mass production, varying from moderate to high throughput.

4. **Versatility**: Capable of handling a wide range of products including powders, granules, liquids, and solids.

5. **Material Compatibility**: Works with various packaging materials like polyethylene, polypropylene, laminated films, and paper.

6. **Bag Styles**: Can produce multiple bag styles such as pillow bags, gusseted bags, and stand-up pouches.

7. **Size Flexibility**: Adjustable to create different package sizes.

8. **Precision**: High accuracy in filling, minimizing product waste.

9. **Hygiene**: Designed to meet food safety and hygiene standards, often made of stainless steel.

10. **Integration**: Easily integrates with upstream and downstream equipment like feeders and palletizers.

### Terms:

1. **Forming Collar**: Device that shapes the packaging material into a tube.

2. **Feeding System**: Mechanism that delivers product to the machine; may include augers, volumetric cups, or weighers.

3. **Film Roll**: Material supply in roll form used for making packages.

4. **Sealing Jaws**: Heated or ultrasonic elements that seal the bags.

5. **Thermal Transfer Printer**: For date coding and batch identification on the packages.

6. **Horizontal Seals and Vertical Seals**: Seals made at the top/bottom and sides of a package, respectively.

7. **Cutting Mechanism**: Device that separates the formed packages.

8. **Control System**: Interface for operating and monitoring the machine, often featuring PLCs and HMIs.

9. **Product Hopper**: Storage area for the product before it is dispensed into the packaging.

10. **Dosing Accuracy**: Measure of how precisely the product quantity is controlled during filling.

By understanding these properties and terms, businesses can leverage VFFS machines for efficient and scalable packaging solutions.

List The Evolution history of “vertical form fill seal machines”

The evolution of vertical form fill seal (VFFS) machines has been marked by several significant milestones, reflecting advancements in technology and changes in market demands.

1. **Early Development (1930s–1950s):**

The concept of automated packaging began in the 1930s. The early VFFS machines were rudimentary, focusing on simple filler-sealers. They primarily packaged snacks and cereals into pre-formed bags, lacking the sophistication and versatility seen today.

2. **Standardization and Expansion (1960s–1970s):**

The 1960s and 1970s saw the standardization of VFFS machines. Innovations like heat-sealing technology allowed for the creation of hermetically sealed packages. The machines became more reliable and began to be used for a broader range of products, including liquids and powders.

3. **Introduction of Electronics and PLCs (1980s):**

Programmable logic controllers (PLCs) revolutionized VFFS machines in the 1980s. These controls enhanced precision and reliability. Machines became faster, with better control over sealing and cutting processes, improving production efficiency and reducing wastage.

4. **Customization and Modularity (1990s):**

The 1990s focused on customization, allowing VFFS machines to cater to specific industry needs. Modular designs were introduced, making it easier to switch out parts and adapt the machines for different products, significantly increasing flexibility and reducing downtime.

5. **Automation and Flexibility (2000s):**

The turn of the millennium brought more advanced sensors, robotics, and improved materials. These advancements led to higher automation levels and flexibility. VFFS machines could now handle a wider variety of packaging materials and forms, improving productivity and adaptability to market trends.

6. **Smart Technology and IoT (2010s–Present):**

The recent decade has seen the incorporation of smart technology and the Internet of Things (IoT). Real-time monitoring, data collection, and predictive maintenance have become standard features. These advancements have further increased efficiency, reduced operational costs, and improved overall machine performance.

The evolution of VFFS machines reflects the broader trends in manufacturing and technology, continuously adapting to meet the needs of various industries efficiently.

How to Select a Reliable vertical form fill seal machines

Selecting a reliable vertical form fill seal (VFFS) machine is crucial for ensuring efficiency and quality in packaging operations. Here are key factors to consider:

1. **Machine Compatibility**: Ensure the VFFS machine is compatible with the product type, packaging material, and bag styles you require. Different machines are tailored for solids, liquids, powders, and granular products.

2. **Quality and Durability**: Look for machines from reputable manufacturers known for high-quality and durable equipment. Investigate the materials used in construction and read reviews or testimonials from other users.

3. **Speed and Efficiency**: Assess the machine’s speed — its capacity to produce the quantity of packages you need within your time frame. Efficient machines should align with your production goals without compromising quality.

4. **Ease of Operation and Maintenance**: Opt for user-friendly machines with intuitive interfaces. Machines that are easy to clean and maintain can reduce downtime and extend the equipment’s lifespan.

5. **Technical Support and Service**: Check the availability of technical support and after-sales service. Reliable manufacturers offer robust support to troubleshoot issues and provide spare parts, ensuring minimal disruption.

6. **Flexibility and Scalability**: Select a machine that can handle a range of packaging sizes and types, offering flexibility as your business grows or evolves.

7. **Cost**: While the initial investment is a consideration, also evaluate the total cost of ownership, including maintenance, energy consumption, and potential downtime.

8. **Compliance and Certification**: Ensure the machine meets industry standards and regulations, especially if you are in regulated industries like food or pharmaceuticals.

9. **Trial and Testing**: Whenever possible, request a demo or trial run with your product to ensure the machine performs as expected.

By thoroughly evaluating these factors, you can select a reliable VFFS machine that meets your operational needs and contributes to your business’s long-term success.

List “vertical form fill seal machines” FAQ

### Vertical Form Fill Seal (VFFS) Machines FAQ

**1. What is a VFFS machine?**

A Vertical Form Fill Seal (VFFS) machine is an automated packaging machine that creates bags from a flat roll of film, fills them with product, and seals them for distribution.

**2. What types of products can be packaged using a VFFS machine?**

VFFS machines can handle a wide range of products, including powders, granules, liquids, snacks, pharmaceuticals, and small hardware items.

**3. How does a VFFS machine work?**

– _Film Feeding:_ The machine pulls film from a roll.

– _Forming:_ The film is shaped into a tube around a forming collar.

– _Sealing:_ Vertical and horizontal heat-sealers create bag seams.

– _Filling:_ Product is dispensed into the formed bag from the top.

– _Final Sealing:_ The top end of the filled bag is sealed.

**4. What materials are compatible with VFFS machines?**

Common materials include polyethylene, polypropylene, laminated films, and paper. Material choice often depends on product specifications and desired shelf life.

**5. How fast are VFFS machines?**

Speeds vary widely but can range from 30 to 200+ bags per minute, depending on machine type, product, and bag size.

**6. What are the benefits of using a VFFS machine?**

– _Efficiency:_ High-speed automated packaging.

– _Versatility:_ Suitable for various products and packaging styles.

– _Compact Footprint:_ Vertically oriented, saving space.

**7. How much does a VFFS machine cost?**

Prices can vary from around $20,000 for a basic unit to $150,000 or more for advanced models with additional features.

**8. What maintenance is required?**

Regular maintenance includes cleaning, inspecting for wear, lubricating moving parts, and software updates. Manufacturer guidelines should be followed for optimal performance.

**9. Can VFFS machines execute custom packaging designs?**

Yes, with the right tooling and programming, these machines can create different bag shapes and custom printed packaging.

**10. Are operator skills required for VFFS machines?**

Basic operations require minimal training, but more complex settings and maintenance might need skilled personnel. Training programs are often provided by manufacturers.

Top 10 FAQ with answer about vertical form fill seal machines for Buyer Sourcing from China

Sure, here are the top 10 frequently asked questions about sourcing vertical form fill seal (VFFS) machines from China, with concise answers:

1. **What Are Vertical Form Fill Seal Machines?**

VFFS machines are automated packaging systems used to form, fill, and seal products into bags. They’re widely used in food, pharmaceutical, and industrial applications.

2. **Why Source VFFS Machines from China?**

China offers competitive pricing, advanced technology, and a wide variety of options. Chinese manufacturers are known for their innovative and cost-effective solutions.

3. **How to Ensure Quality When Buying from China?**

Perform thorough research on the manufacturer, check reviews, ask for certifications (such as ISO or CE), and request sample machines if possible. On-site inspections or third-party quality audits are advisable.

4. **What Are the Key Features to Look for in a VFFS Machine?**

Look for reliability, speed (bags per minute), flexibility in bag size, ease of use, compatibility with different materials, and after-sales support. Advanced features like touchscreens and remote diagnostics are also beneficial.

5. **Do Chinese Manufacturers Offer Customization?**

Yes, many Chinese manufacturers can customize VFFS machines to meet specific requirements, such as different bag sizes, packaging materials, and additional functionalities.

6. **How to Deal with Language Barriers?**

Most reputable Chinese manufacturers have English-speaking sales and support teams. Utilize clear written communication and video calls to bridge any language gaps.

7. **What Are Typical Lead Times?**

Lead times can vary from a few weeks to several months, depending on the complexity of the machine and the manufacturer’s production schedule.

8. **What Is the Approximate Cost?**

Basic models may start around $15,000, while more advanced or customized machines can cost upwards of $100,000. Always get multiple quotes for comparison.

9. **How Is Shipping Handled?**

Shipping can be arranged via sea or air freight. Manufacturers often assist with logistics, but it’s essential to clarify terms (FOB, CIF, etc.) and any associated costs up front.

10. **Are Spare Parts and Technical Support Available?**

Reputable manufacturers provide spare parts and technical support. Confirm the availability of parts, warranty terms, and support options such as online troubleshooting or on-site assistance before purchasing.

These answers should help you make an informed decision when sourcing VFFS machines from China.