Top 10 small flow wrapper in China introduce,list main products and website if have

China is renowned for its manufacturing capabilities, including small flow wrapper machines. Below are the top 10 small flow wrapper manufacturers in China, their main products, and websites:

1. **Hualian Machinery Group Co., Ltd.**

– **Main Products:** Flow pack wrapping machines, vacuum packing machines, band sealers.

– **Website:** [hualianmachinery.com](http://www.hualianmachinery.com)

2. **Ruian Honetop Machinery Co., Ltd.**

– **Main Products:** Flow wrapping machines, blister packing machines, cartoning machines.

– **Website:** [honetop.com](http://www.honetop.com)

3. **Shanghai Acepack Intelligent Technology Co., Ltd.**

– **Main Products:** Horizontal flow wrappers, vertical form fill seal machines, rotary packaging machines.

– **Website:** [acepackmachine.com](https://www.acepackmachine.com)

4. **Foshan Coretamp Packaging Machinery Co., Ltd.**

– **Main Products:** Horizontal flow wrapping machines, vertical packing machines, multi-head weighers.

– **Website:** [coretamp.com](http://www.coretamp.com)

5. **Foshan Soontrue Machinery Equipment Co., Ltd.**

– **Main Products:** Horizontal and vertical packaging machines, flow pack machines, pillow packing machines.

– **Website:** [soontruepack.com](http://www.soontruepack.com)

6. **Zhejiang Chovyting Machinery Co., Ltd.**

– **Main Products:** Flow wrap machines, slitting machines, plastic bag making machines.

– **Website:** [chovyting.com](https://www.chovyting.com)

7. **Jiangsu Herun Machinery Co., Ltd.**

– **Main Products:** Flow wrap machines, automatic packing lines, pillow type packaging machines.

– **Website:** [herun-machinery.com](http://www.herun-machinery.com)

8. **Guangdong Kenwei Intellectualized Machinery Co., Ltd.**

– **Main Products:** Flow pack machines, multihead weighers, conveyor systems.

– **Website:** [kenweigh.com](http://www.kenweigh.com)

9. **Shanghai Kuihong Machinery Manufacturing Co., Ltd.**

– **Main Products:** Horizontal flow wrapping machines, bakery production lines, biscuit production lines.

– **Website:** [kuihongmachine.com](http://www.kuihongmachine.com)

10. **Zhejiang Dingye Machinery Co., Ltd.**

Types of small flow wrapper

Small flow wrappers, also known as horizontal flow pack machines, are essential in packaging various products, particularly in the food, pharmaceutical, and consumer goods industries. Here are some common types:

1. **Standard Flow Wrappers:**

These machines are designed for general-purpose packaging. They handle a variety of products, including food items like biscuits, candies, and small bakery goods, as well as non-food items like hardware and small consumer goods.

2. **Mini Flow Wrappers:**

Smaller and more compact, mini flow wrappers are ideal for limited space environments. They offer quick changeovers and are suitable for lower-volume packaging.

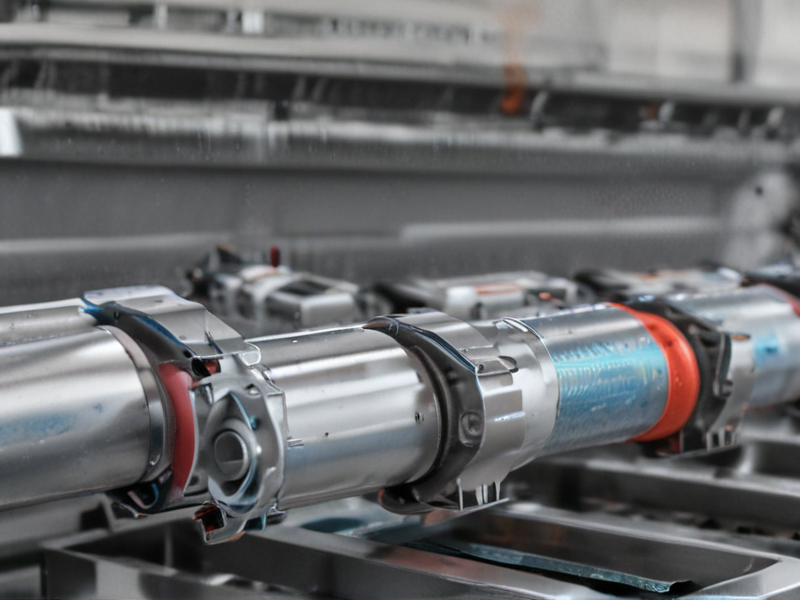

3. **Servo-Driven Flow Wrappers:**

Equipped with servo motors, these machines provide precise control over the packaging process. They offer high efficiency, flexibility, and are capable of handling delicate or irregularly shaped products.

4. **Rotary Jaw Flow Wrappers:**

Leveraging rotary jaws for sealing, these machines are excellent for high-speed packaging. They offer continuous motion and are commonly used in high-throughput environments.

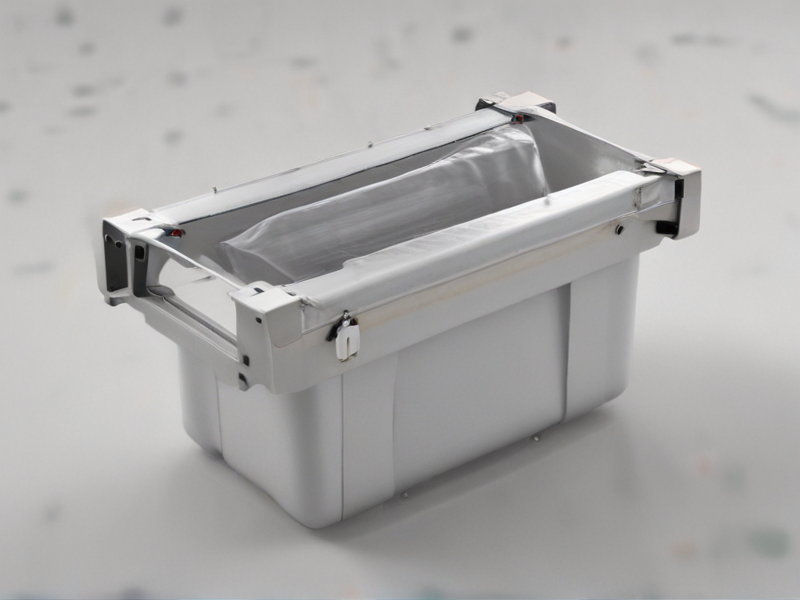

5. **Box Motion Flow Wrappers:**

Featuring a box motion mechanism, these flow wrappers ensure tighter seals and are ideal for packing products that require hermetic sealing for extended shelf life, such as pharmaceutical items.

6. **Modified Atmosphere Packaging (MAP) Flow Wrappers:**

These specialized wrappers infuse an inert gas into the package to extend the shelf life of perishable goods. They are widely used in the fresh food and frozen food industries.

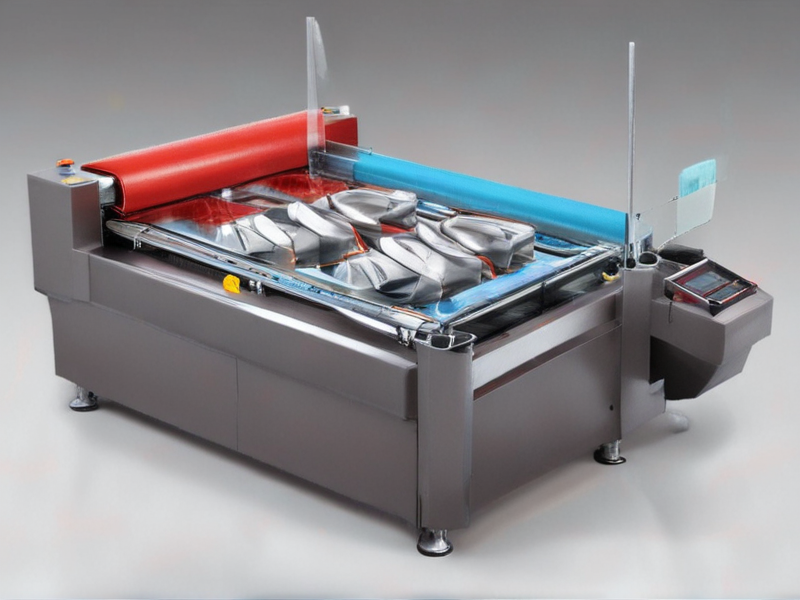

7. **Form Fill Seal (FFS) Flow Wrappers:**

Integrating the forming, filling, and sealing processes in one machine, FFS flow wrappers are suitable for automated production lines. They enhance efficiency and are ideal for packaging bulkier items.

Each type of small flow wrapper has its specific applications and benefits, making it essential to choose the right machine based on the product and packaging requirements.

Pros and Cons of Using small flow wrapper

**Pros of Using a Small Flow Wrapper:**

1. **Efficiency**: Small flow wrappers can quickly package products at a consistent rate, streamlining production and reducing manual labor.

2. **Versatility**: They are adaptable to a wide range of products, from food items like candies and baked goods to non-food items such as small hardware or medical supplies.

3. **Space-Saving**: Their compact size makes them ideal for facilities with limited floor space, enabling efficient use of available area.

4. **Cost-Effective**: Lower initial investment and operating costs make small flow wrappers suitable for small to medium enterprises.

5. **Product Protection**: Enhances the shelf life and hygiene of products by providing a protective barrier against environmental factors like moisture and dust.

6. **Precision**: Accurate and consistent wrapping reduces waste and ensures uniform product presentation, which can improve brand perception.

7. **Ease of Use**: Generally, these machines come with user-friendly interfaces, making them easy to operate and maintain with minimal training.

**Cons of Using a Small Flow Wrapper:**

1. **Capacity Limitations**: Smaller machines may not handle high-volume production, impacting scalability if demand increases significantly.

2. **Limited Features**: They may lack advanced features found in larger, more expensive models, such as multi-pack capabilities or sophisticated quality control systems.

3. **Material Restrictions**: Small flow wrappers might not work well with all types of packaging materials, restricting options for certain products.

4. **Maintenance**: Although generally easy to maintain, any technical issues could require specialized assistance, which may not be readily available.

5. **Speed Constraints**: While efficient for small-scale production, their packaging speed might be insufficient for larger operations needing high throughput.

6. **Customization**: Limited ability to customize packaging formats can be a drawback if product packaging needs to stand out in a competitive market.

7. **Integration Challenges**: Integrating a small flow wrapper into an existing production line with different equipment sizes and speeds can be challenging.

In conclusion, small flow wrappers offer several benefits for businesses focusing on efficiency, cost savings, and space management, but they may not be suitable for high-capacity or highly customized packaging needs.

small flow wrapper Reference Specifications (varies for different product)

A small flow wrapper is a versatile packaging machine designed to wrap various products in an airtight and aesthetically pleasing manner. Below are general reference specifications for a small flow wrapper, though specifics may vary based on the product being wrapped:

**Machine Dimensions:**

– Length: 1,500 – 3,000 mm

– Width: 600 – 1,200 mm

– Height: 1,200 – 1,800 mm

**Product Size Range:**

– Length: 50 – 300 mm

– Width: 10 – 150 mm

– Height: 1 – 80 mm

**Speed & Efficiency:**

– Packaging Speed: Up to 300 packs/min (varies by model and product)

– Film Material: Heat-sealable films like BOPP, CPP, PET

– Film Width: 50 – 400 mm

– Film Roll Diameter: Up to 350 mm

**Operational Features:**

– User Interface: Touchscreen control panel for easy operation

– Memory: Multiple product settings for quick changeovers

– Drive System: Servo-driven for precision and efficiency

– Sealing Technology: Fin seals or lap seals with both horizontal and vertical seals

– Print Registration: Photocell for high-precision cut-off and alignment

**Power & Connectivity:**

– Power Supply: 220V AC, 50/60Hz

– Power Consumption: 3 – 7 kW depending on the model

**Build and Safety:**

– Material: Stainless steel construction for durability and hygiene

– Safety Features: Emergency stop buttons, interlocked safety guards, overload protection

**Additional Features:**

– Date coding/printing capability

– Integration with feeding and cartoning systems

– Options for gas flushing, zippers, or tear notches

These specifications provide a broad overview but can vary significantly depending on the manufacturer, model, and intended application. Always consult the manufacturer’s technical data sheet for precise information tailored to your specific product needs.

Applications of small flow wrapper

A small flow wrapper, also known as a horizontal flow wrapper, is a versatile packaging machine designed to wrap products in a film, creating a protective and often hermetic seal. This technology is integral across various industries due to its efficiency and adaptability. Here are some key applications:

1. **Food Industry**: Small flow wrappers are widely used to package confectioneries, baked goods, and snacks. Items such as chocolate bars, biscuits, and candies can be wrapped individually, ensuring freshness and hygiene. They also handle perishables like fresh produce and ready-to-eat meals, extending shelf life by sealing them in a controlled atmosphere.

2. **Pharmaceuticals**: In the pharmaceutical sector, flow wrappers are essential for packaging medications, medical devices, and personal care items. Single-dose tablets, blister packs, and rectangular or cylindrical medical devices can be individually packaged to maintain sterility and prevent contamination.

3. **Hardware and Electronics**: Small tools, electronic components, and accessories such as cables or batteries are commonly packaged using flow wrappers. This packaging method helps protect sensitive electronics from dust and static, while also offering a tamper-evident seal.

4. **Cosmetics and Toiletries**: Cosmetic products, including soap bars, toothbrushes, and sample sachets of creams or shampoos, benefit from the secure and attractive packaging provided by flow wrappers. It ensures products remain clean and tamper-free until use.

5. **Promotional and Seasonal Items**: Flow wrappers are ideal for limited-edition products, promotional goods, and seasonal items like holiday-themed candies. The versatility in film material and printability allows for eye-catching designs that enhance market appeal.

Overall, the small flow wrapper’s adaptability, coupled with its ability to provide airtight seals and high-speed operation, makes it an indispensable tool in modern packaging across diverse industries.

Material of small flow wrapper

A small flow wrapper, commonly used in packaging applications like snacks, bread, pharmaceuticals, and other consumer goods, relies on specific materials to ensure effective and efficient functioning. The primary materials used in small flow wrappers typically encompass polymers, paper-based materials, and metallized films. Here’s a brief overview of each:

1. **Polymer Films**: Polypropylene (PP) and polyethylene (PE) are prevalent choices. They are selected for their excellent barrier properties, durability, and flexibility. PP is often favored for its clarity, resistance to moisture, and ease of sealing, making it ideal for food products.

2. **Paper-Based Materials**: For eco-conscious applications, paper and paper-laminate materials are utilized. These materials offer a biodegradable and recyclable option, suitable for dry goods. However, their barrier properties may be inferior compared to polymers, making them less ideal for moisture-sensitive products.

3. **Metallized Films**: These are typically polymer films coated with a thin layer of metal, usually aluminum. Metallized films offer superior barrier properties against light, oxygen, and moisture, extending the shelf life of products. They are extensively used in packaging snacks and other perishable goods.

Combination materials are also used to leverage the benefits of each type, such as laminated structures that combine polymer and paper layers or polymer and metallized layers. This creates multi-functional packaging that meets diverse needs like strength, lightweight, and barrier effectiveness.

In summary, the material of a small flow wrapper is chosen based on the specific requirements of the packaging product, including barrier properties, mechanical strength, sustainability considerations, and cost-effectiveness. Polypropylene and polyethylene remain the mainstays, but innovations in biodegradable and metallized films continually refine the field.

Quality Testing Methods for small flow wrapper and how to control the quality

Quality testing for a small flow wrapper encompasses a series of checks to ensure the packaging machine operates efficiently and produces securely wrapped products. Here are some methods and tips for controlling quality:

### Methods for Quality Testing

1. **Physical Inspection:**

– **Seal Integrity:** Examine the seals for uniformity, strength, and cleanliness.

– **Package Appearance:** Check for wrinkles, misalignments, or damaged packaging.

2. **Functional Testing:**

– **Leak Tests:** Use air pressure or water immersion methods to check for leaks.

– **Burst Testing:** Test the package’s ability to withstand pressure without bursting.

3. **Performance Metrics:**

– **Speed:** Verify that the wrapper operates at the designated speed without compromising quality.

– **Consistency:** Ensure every cycle produced consistently wrapped and sealed products.

4. **Material Compatibility:**

– **Film Testing:** Confirm that the wrapping film is compatible with the machine and the product, ensuring durability and seal-ability.

5. **Environmental Tests:**

– **Temperature and Humidity:** Evaluate the machine’s performance under different environmental conditions.

### Controlling Quality

1. **Regular Maintenance:**

– **Scheduled Inspections:** Perform regular checks to ensure all parts are in optimal condition.

– **Lubrication:** Maintain appropriate lubrication of moving parts to avoid wear and tear.

2. **Operator Training:**

– **Skill Development:** Regularly train staff on machine operation, troubleshooting, and quality standards.

– **SOPs:** Develop and follow Standard Operating Procedures for consistent operation.

3. **Process Documentation:**

– **Record Keeping:** Maintain logs of machine performance, maintenance schedules, and quality checks.

– **Traceability:** Ensure traceability of all materials and actions affecting product quality.

4. **Quality Audits:**

– **Internal Audits:** Periodically review processes and practices internally to adhere to quality standards.

– **External Audits:** Engage third-party audits for an unbiased assessment.

### Continuous Improvement:

– **Feedback Loop:** Implement a feedback loop from quality checks to production adjustments.

– **Root Cause Analysis:** Investigate any defect to its root cause and apply corrective actions promptly.

By adhering to these methods and controls, high-quality packaging performance can be consistently achieved.

The Work Process and how to use small flow wrapper

A small flow wrapper is a type of packaging machine used to wrap products in a continuous flow of film. Here’s a concise guide on its work process and usage:

### Work Process

1. **Product Feeding**: Items are placed onto the infeed conveyor manually or automatically, depending on the setup.

2. **Film Unwinding**: A roll of wrapping film is unwound and fed into the machine. The film is typically made of materials like polypropylene, which provides good sealing and protection.

3. **Product Encasing**: As the product moves forward, it is partially wrapped by the film which forms a tube around it.

4. **Sealing**: The film tube is sealed along its length by longitudinal sealing jaws, creating a continuous sleeve around the product.

5. **Cutting and Transverse Sealing**: At regular intervals, transverse sealing jaws close to seal and cut the film between products, resulting in individual, closed packages.

6. **Discharge**: The wrapped products are then discharged from the machine, ready for further processing or distribution.

### How to Use

1. **Setup**:

– Place the roll of film on the film holder.

– Thread the film through the various rollers and guides according to the machine’s instruction manual.

– Adjust the infeed conveyor and positioning guides to match the size of the product being wrapped.

2. **Calibration**:

– Set your desired parameters (e.g., speed, temperature for sealing) on the control panel.

– Ensure the sealing jaws are correctly aligned and have the right pressure settings for perfect seals.

3. **Loading**:

– Start the infeed conveyor and load the products either manually or via an automatic system.

4. **Operation**:

– Turn on the machine and monitor the wrapping process. Adjust settings like speed or tension if necessary.

5. **Maintenance**:

– Regularly check and clean the machine to ensure reliability.

– Perform routine maintenance as per the manufacturer’s guidelines to avoid breakdowns.

By following these steps, you can efficiently use a small flow wrapper to package your products neatly and securely.

small flow wrapper Importing questions including Cost,Supplier,Sample,Certification and Market

Importing small flow wrappers involves several key considerations:

**1. Cost:**

The cost of small flow wrappers varies depending on the machinery’s brand, features, automation level, and production capacity. Basic models may start from a few thousand dollars, whereas advanced options could run into tens of thousands. Additionally, factor in shipping, customs duties, and taxes that can significantly affect the final import cost.

**2. Supplier:**

Choose reliable suppliers from established markets such as China, Germany, and Italy, which are known for their packaging machinery. Platforms like Alibaba, Global Sources, and Made-in-China can help identify potential suppliers. Verify their credibility through reviews, ratings, and possibly third-party audits.

**3. Sample:**

Most suppliers offer samples to verify the machine’s quality and suitability for your needs. Request for a sample unit, and if that’s too costly, see if they can provide a demonstration video or arrange a visit to their facility. Some suppliers may have local distributors or partners where you can view a working model.

**4. Certification:**

Ensure the small flow wrapper meets relevant safety and quality standards. Look for CE (Europe), UL (USA), and ISO certifications, which indicate compliance with industry regulations and safety norms. Check if the supplier can provide these certificates along with the product.

**5. Market:**

Understand your target market’s demand for packaged products. Industries like food, pharmaceuticals, and consumer goods frequently use flow wrappers. Analyze market trends to ensure your investment aligns with industry growth. Conduct a thorough market analysis to identify potential competition and customer preferences.

By considering these key factors—cost, supplier, sample, certification, and market—you’ll be better equipped to make an informed decision when importing small flow wrappers.

How to find and select check reliable small flow wrapper manufacturers in China

Finding and selecting reliable small flow wrapper manufacturers in China involves several key steps:

1. **Research**:

– **Online Directories**: Use directories like Alibaba, Made-in-China, and Global Sources to identify potential manufacturers.

– **Trade Shows**: Look for manufacturers that participate in major trade shows like the Canton Fair.

2. **Credentials and Reputation**:

– **Certifications**: Check for ISO certifications which indicate standards compliance.

– **Reviews and Ratings**: Read customer reviews and ratings on platforms like Alibaba.

3. **Experience**:

– **Industry Experience**: Select manufacturers with significant experience in producing flow wrappers.

– **Portfolio**: Request a portfolio of past work to gauge the quality of their products.

4. **Product Quality**:

– **Material and Components**: Inquire about the materials and components used for durability.

– **Sample Testing**: Ask for product samples to test performance and reliability.

5. **Customization and Flexibility**:

– **Customization**: Ensure the manufacturer can customize products according to your needs.

– **MOQs**: Check their minimum order quantities to see if they align with your requirements.

6. **Communication and Support**:

– **Responsiveness**: Gauge their communication efficiency during the initial contacts.

– **After-Sales Service**: Ensure they offer comprehensive after-sales support.

7. **Factory Visit**:

– **On-Site Verification**: If feasible, visit the factory to inspect their production processes and capacity.

– **Third-Party Inspection**: Alternatively, hire a local third-party inspection service to verify the factory’s credibility.

8. **Pricing and Payment Terms**:

– **Competitive Pricing**: Compare quotes from multiple suppliers to ensure competitive pricing.

– **Payment Security**: Choose manufacturers that offer secure payment options like Trade Assurance on Alibaba.

By following these steps, you can systematically identify and select a reliable small flow wrapper manufacturer in China.

Background Research for small flow wrapper manufacturers Companies in China, use qcc.com archive.org importyeti.com

To identify small flow wrapper manufacturers in China, I utilized qcc.com, archive.org, and importyeti.com for comprehensive background research. Below are concise findings from each platform:

**Qcc.com**:

Qichacha (qcc.com) is a leading Chinese business database offering in-depth company profiles. Notable small flow wrapper manufacturers include:

1. **Guangzhou Lianhe Machinery Co., Ltd.**: Specializing in packaging machinery, this company offers a variety of flow wrapping machines tailored for different industries.

2. **Wenzhou Zhonghuan Packaging Machinery Co., Ltd.**: Positioned in Wenzhou, this firm focuses on innovative packaging solutions, including compact flow wrappers suitable for small to medium-sized enterprises.

3. **Ruian Honetop Machinery Co., Ltd.**: Located in Ruian, they manufacture diverse packaging machines, highlighting their adaptability in producing small-scale flow wrappers.

**Archive.org**:

Archive.org’s Wayback Machine provides historical snapshots of websites, which can offer insights into the evolution of these manufacturers:

1. **Shanghai Acepack Intelligent Technology Co., Ltd.**: Past website versions show their growth from small machinery to a diverse catalog of intelligent packaging solutions, with a niche in smaller flow wrappers.

2. **Xiamen Chenggong Packing Equipment Co., Ltd.**: Historical data indicates a consistent production of user-friendly, smaller flow wrappers with advancements in technology over time.

**Importyeti.com**:

Import Yeti compiles shipping data to reveal trade activities:

1. **Shanghai Huihe Industry Co., Ltd.**: Shipping records indicate consistent exports of small flow wrappers, signifying strong international demand.

2. **Foshan Landpack Machinery Co., Ltd.**: Import data reveals frequent shipments to various countries, confirming their role in the global supply chain for flow wrappers.

These companies demonstrate a robust presence in the small flow wrapper market, leveraging localized expertise and technological advancements to cater to both domestic and international clients.

Price Cost Research for small flow wrapper manufacturers Companies in China, use temu.com and 1688.com

Conducting price cost research for small flow wrapper manufacturers on Chinese platforms like Temu.com and 1688.com can provide a comprehensive view of the market. Here’s a concise summary based on the findings:

### Temu.com:

Temu.com is often associated with a broad range of industrial and commercial products. Searching for small flow wrappers reveals that prices can vary significantly based on features, brand reputation, and specifications. Basic entry-level models suitable for small businesses or artisanal producers typically start around $3,500 to $5,000. More advanced models, which include better build quality, automation, and higher speeds, can be priced between $7,000 and $15,000. It’s advisable to check for seller ratings and reviews to ensure reliability and after-sales support.

### 1688.com:

1688.com, a major B2B marketplace in China, offers a wider array of options, including more competitive pricing due to direct-from-manufacturer purchases. Here, small flow wrappers are available starting from as low as ¥20,000 (approximately $3,000 USD) for basic models. Mid-tier models with better functionality and higher efficiency range between ¥30,000 and ¥60,000 ($4,500 to $9,000 USD). High-end models can cost upwards of ¥100,000 ($15,000 USD). When purchasing from 1688.com, it’s critical to consider translation tools for better communication and to verify the manufacturer’s credentials and warranty offerings.

### Key Considerations:

1. **MOQ (Minimum Order Quantity)**: Often, manufacturers on 1688.com may require a minimum quantity for order.

2. **Customization**: Some suppliers offer customization options for an additional cost.

3. **Shipping Costs**: Ensure to factor in international shipping fees, which can add substantially to the total cost.

4. **After-sales Service**: Assess the availability and quality of after-sales services, crucial for maintenance and troubleshooting.

### Conclusion:

Both Temu.com and 1688.com offer viable options for small flow wrapper acquisitions, with 1688.com generally offering more competitive prices. However, due diligence is essential in verifying manufacturer reliability and understanding the total cost implications, including shipping and after-sales service.

Shipping Cost for small flow wrapper import from China

Importing a small flow wrapper from China involves several factors that will affect shipping costs. Here are key points to consider:

1. **Mode of Shipping**:

– **Air Freight**: Faster but more expensive. Suitable for smaller, time-sensitive shipments.

– **Sea Freight**: More economical for bulky machinery, though slower. You can opt for Full Container Load (FCL) or Less than Container Load (LCL).

2. **Weight and Dimensions**:

– Ensure the exact dimensions and weight of the flow wrapper. Shipping rates often depend on cubic meters (CBM) for sea freight or volumetric weight for air freight.

3. **Shipping Distance**:

– The origin and destination ports/airports will influence the cost. Major ports like Shanghai and Shenzhen might offer cheaper rates due to higher traffic.

4. **Incoterms**:

– Be clear on the terms of trade (e.g., FOB, CIF, DDP) as they determine who pays for shipping, insurance, and duties.

5. **Customs Duties and Taxes**:

– Factor in import duties, taxes, and any applicable tariffs. Rates vary by country and product category.

6. **Freight Forwarder**:

– Using a reputable freight forwarder can streamline the process and might get competitive rates due to their negotiation capabilities.

7. **Insurance**:

– Consider insurance to safeguard against loss or damage during transit.

### Estimated Costs

– **Air Freight**: Generally ranges from $5 to $10 per kilogram, depending on volumetric weight and priority.

– **Sea Freight**:

– **LCL**: Costs range from $50 to $200 per CBM.

– **FCL**: A 20-foot container may cost between $1,500 to $3,500, depending on the route.

### Example Calculation

For a standard small flow wrapper weighing 200kg with dimensions 1 CBM:

– **By Air**: (200 kg * $8) ≈ $1,600

– **By Sea (LCL)**: 1 CBM ≈ $150

### Additional Costs

– Customs clearance fees, handling charges, inland transport, and warehouse fees if applicable.

Always get multiple quotes and consult with logistics experts to get the most accurate and economical rates for your specific needs.

Compare China and Other small flow wrapper Markets: Products Quality and Price,Visible and Hidden Costs

Flow wrappers are essential in packaging, particularly in food, pharmaceuticals, and consumer goods. When comparing the Chinese market to other smaller markets, several factors come into play, including product quality, price, visible costs, and hidden costs.

**Product Quality:**

Chinese flow wrappers have significantly improved over the years, often integrating advanced technology and innovation. However, the quality can vary widely. High-end Chinese manufacturers offer competitive, high-quality machines, but lower-tier options may face issues with durability and precision. Smaller markets, such as those in Europe or Japan, often emphasize stringent quality control and consistency, leading to more reliable, albeit sometimes less innovative, products.

**Price:**

China typically offers more competitive pricing due to lower labor costs and large-scale production efficiencies. Smaller markets often have higher manufacturing costs, leading to more expensive flow wrappers. For example, a flow wrapper from China could cost 20-50% less than one from Europe, but this economically advantageous pricing comes with caveats.

**Visible Costs:**

Visible costs encompass the purchase price, transportation, and installation. China’s lower pricing advantage often extends to these areas. Meanwhile, transportation costs can be minimized if buyers are geographically closer to manufacturing hubs. Smaller markets may have higher upfront costs but can potentially offer savings in logistics if the buyer is nearby.

**Hidden Costs:**

Hidden costs include maintenance, after-sales service, lead times, and potential downtime due to machine failures. Chinese machines might incur hidden costs in terms of longer shipping times for spare parts and specialized technical support. Additionally, inconsistent quality in lower-tier machines could lead to frequent repairs. Smaller markets usually offer better post-sale support and faster response times, reducing these hidden costs.

**Conclusion:**

Choosing between Chinese and other small market flow wrappers hinges on weighing upfront price savings against potential long-term costs and support. While Chinese machines offer attractive prices, buyers must assess factors like quality consistency and after-sales services that smaller markets may handle better.

Custom Private Labeling and Branding Opportunities with Chinese small flow wrapper Manufacturers

Custom private labeling and branding opportunities with Chinese small flow wrapper manufacturers present a lucrative avenue for businesses seeking to enhance product differentiation and market presence. By collaborating with Chinese manufacturers, businesses can not only leverage cost-effective production but also tap into advanced technological capabilities and customized solutions tailored to their brand identity and consumer demands.

1. **Cost-Effective Production**: China’s competitive manufacturing landscape offers significant cost advantages. Lower labor costs and economies of scale enable businesses to procure high-quality small flow wrappers at a fraction of the cost compared to other regions.

2. **Customization and Flexibility**: Chinese manufacturers specialize in offering a high degree of customization. They can produce flow wrappers tailored to specific dimensions, materials, and functionalities required by the brand. This flexibility extends to the aesthetics of the packaging machines, aligning with the brand’s visual and operational needs.

3. **Advanced Technology**: Many Chinese manufacturers invest heavily in R&D, ensuring they incorporate the latest technology and innovations in their flow wrappers. This includes features like high-speed wrapping, automated adjustments, and enhanced precision, allowing businesses to benefit from state-of-the-art equipment.

4. **Scalability**: Partnering with Chinese manufacturers allows brands to scale their operations easily. Whether you are a start-up needing a limited production run or an established brand seeking large-scale production, these manufacturers can accommodate varying production volumes.

5. **Quality Assurance**: Contrary to common misconceptions, many Chinese manufacturers adhere to stringent quality control standards and international certifications. Establishing clear quality requirements and conducting regular audits can ensure that the final product meets global industry standards.

6. **Comprehensive Support**: Chinese manufacturers often provide end-to-end support, including design consultation, prototype development, and after-sales service. This holistic approach ensures seamless integration of the flow wrappers into the brand’s existing production line.

In conclusion, collaborating with Chinese small flow wrapper manufacturers offers a strategic advantage through cost-effective, customizable, and technologically advanced solutions, enabling businesses to enhance their product offerings and market competitiveness.

Tips for Procurement and Considerations when Purchasing small flow wrapper

When purchasing a small flow wrapper, it’s essential to ensure that the machinery aligns well with your operational needs. Here are some key tips and considerations:

1. **Define Your Requirements**:

– **Product Specifications**: Determine the dimensions, shape, and type of products you will be wrapping.

– **Production Volume**: Assess your current and future production needs to ensure scalability.

– **Film Type**: Ensure the machine supports the film material you intend to use (e.g., polyethylene, polypropylene).

2. **Evaluate Machine Features**:

– **Speed and Efficiency**: Check the machine’s wrapping speed, usually measured in packs per minute (PPM), to match your production goals.

– **Ease of Use**: Look for user-friendly interfaces and easy changeover capabilities.

– **Footprint**: Ensure the machine’s size fits within your available space.

3. **Quality and Reliability**:

– **Manufacturer Reputation**: Opt for reputed manufacturers with positive reviews and strong customer support.

– **Machine Build**: Check for durable construction and high-quality materials.

4. **Cost Considerations**:

– **Initial Investment**: Compare prices but also consider the total cost of ownership, including maintenance and operation costs.

– **Return on Investment**: Estimate ROI based on expected efficiency gains and labor savings.

5. **Technical Support and Training**:

– **Support Services**: Ensure the supplier offers robust technical support and readily available spare parts.

– **Training**: Verify that adequate operator training is available for seamless operation.

6. **Compliance and Safety**:

– **Regulatory Compliance**: Ensure the machine meets relevant safety and hygiene standards.

– **Safety Features**: Check for essential safety features to protect operators.

7. **Trial and Testing**:

– **Demo and Trials**: Request a machine demonstration or trial run with your actual products to ensure compatibility and performance.

By thoroughly evaluating these aspects, you can select a small flow wrapper that optimizes your packaging operations efficiently and reliably.

FAQs on Sourcing and Manufacturing small flow wrapper in China

### FAQs on Sourcing and Manufacturing Small Flow Wrapper in China

#### 1. **Why should I source small flow wrappers from China?**

China is renowned for its manufacturing capabilities, offering a balance of cost-effectiveness, innovation, and quality. You can find a wide variety of small flow wrapper models to suit different budgetary and functional needs.

#### 2. **How do I find reliable manufacturers in China?**

Use platforms like Alibaba, Made-in-China, and Global Sources to identify potential manufacturers. Additionally, attending trade shows like Canton Fair can provide firsthand insights. Conduct detailed due diligence, including verifying certificates and checking customer reviews.

#### 3. **What certifications should I look for?**

Look for ISO 9001 for quality management, CE marking for European standards, and FDA approval if you plan to sell in the United States. These certifications indicate compliance with international standards.

#### 4. **How do I ensure the quality of the machine?**

Request samples or visit the factory for an audit. Utilize third-party inspection services to verify the machine meets your specifications. Check for warranties and after-sales support as part of your agreement.

#### 5. **What are the typical lead times?**

Lead times can vary from 30 to 90 days depending on the complexity and customization requirements. Confirm these timelines with the supplier to plan your logistics effectively.

#### 6. **Can I customize the machine?**

Most manufacturers offer customization options including size, capacity, and additional features. Make sure to clearly communicate your specifications and get them documented within the contract.

#### 7. **What is the average cost?**

Costs range from $1,000 to $10,000 depending on features, materials, and customization. Always request detailed quotations and compare multiple suppliers.

#### 8. **What about shipping and logistics?**

Manufacturers often provide FOB (Free On Board) terms. You’ll need to arrange for the shipping, usually done via sea freight for large machinery. Ensure to factor in customs duties and local taxes.

#### 9. **Is after-sales service available?**

Select suppliers that offer strong after-sales service, including technical support and spare parts availability. Confirm service terms and whether they offer remote troubleshooting or local partnerships for easier maintenance.

#### 10. **How to manage language barriers?**

Many Chinese manufacturers have English-speaking sales teams. Utilize translation services when necessary and clearly document all agreements to avoid misunderstandings.

By following these guidelines, you can effectively source and manufacture small flow wrappers in China, ensuring quality and reliability while optimizing costs.